If you have been paying attention to the product developments over the last few years, reworkable underfills are gaining more and more traction over non reworkable ones.

Without thinking about it too much, it kinda makes sense, but why and when would you ever need a reworkable underfill? And what’s the difference between a reworkable and a non reworkable one?

To get to that let’s start with a typical rework process. There are two steps to it, that shouldn’t take longer than 5 minutes in total. Removing the components and cleaning the board. If you want to enumerate them:

Removing components

- Preheat board (~100sec)

- Reflow components (~100 sec)

- Manually debond components

Cleaning the board

- Apply tacky flux

- Scrape underfill residue

- Pick up remaining residue with flux saturated cotton swab

- Cool down board and wipe with solvent

Marked in red are the steps where things can go horribly wrong and where reworkable underfills shine over classic ones.

Non reworkable underfills

Removing a component and scraping an underfill that wasn’t designed with reworking in mind can be quite damaging for the board. Non reworkable underfills tend to have high adhesion to solder masks. As a result, scraping them can completely destroy the pads and traces and heavily damage the solder mask.

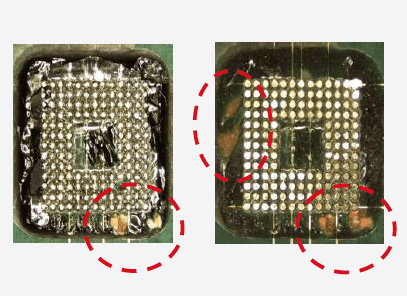

By using a classic product, the board surface will have more than 50% underfill residue after debonding and it will most likely damage the surface. Even after trying to clean it there will be 30-40% residue and at least 10% of the solder mask will be damaged.

Reworkable underfills

With a reworkable underfill, there will be minimal residue after debonding. Reworkable underfills have low adhesion to solder mask so mechanical scrapping is easy. This means that after the cleaning step the board surface will be undamaged and residue free.

So when you are dealing with expensive production motherboards that might need to be repaired or when you are towards the end of the assembly process (finished part) and something needs fixing, a reworkable underfill is what you need and what will save the day.

Moreover, you are in for a treat since many current generation epoxy underfills such as LOCTITE ECCOBOND UF3811 or UF3812 are already reworkable. Maybe you just discovered a new feature for something you’ve already qualified.

Does this make non reworkable underfills bad? Well, no, obviously not. There are many applications where reworking is not even a viable option either from a financial or from a process standpoint so you would never have to worry about reworking your board.

Maybe you just want a material that has been formulated without any reportable REACH SVHCs and is not CMR classified. If so, LOCTITE ECCOBOND UF1173 is the right product for you.

Or maybe you just want to know more about underfills or have a question about your very custom, very tricky and very demanding package. In that case we will be very happy to help you if you Contact us or if you leave a comment below.