Slot insulation

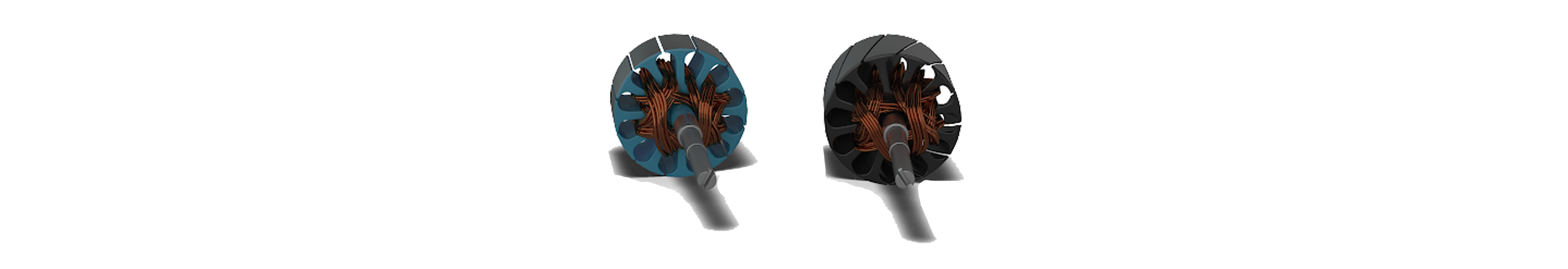

Motor Armatures

A motor armature is the rotating component of an electric machine that interacts with the magnetic field to produce torque in motors. The armature consists of a laminated iron core, windings of conductive wire, and a commutator (in DC machines) or slip rings (in AC machines) to transfer current between stationary and rotating parts.

Armatures can operate under different configurations depending on the type of machine and excitation method. They are found in DC motors, synchronous machines, and induction machines, each with specific winding arrangements and magnetic field interactions. In DC motors, the armature is typically located on the rotor, while in some AC machines the armature can be on the stator.

In a DC motor, electromechanical energy conversion occurs through the following processes:

Current induction in the windings: Current supplied to the armature windings generates a magnetic field that interacts with the stator’s magnetic field.

Force generation: According to Lorentz’s law, the interaction of the armature’s magnetic field with the stator field produces a force on the conductors, generating torque and causing rotation.

Commutation: The commutator and brushes reverse the current direction in the armature windings as the rotor turns, ensuring continuous torque in the same rotational direction.

As in other electromechanical systems, the overall principle of operation is the conversion of electrical power into mechanical motion, with the armature acting as the key intermediary between the electrical input and the mechanical output.

Where Motor Armatures are Found

Industrial motors include power tools, home appliances, and industrial motors. In the automotive industry, motors are used for enclosures, windshield wipers, seat adjusters, window lifts, and fuel pumps. Quality cars can have up to 130 motors.

Motor Armature Insulation Classes

What is Insulation Class?

A motor’s insulation class is the maximum (hot spot) temperature at which the insulation can be operated and still have an average life of 20,000 hours. The Rule of Thumb is that a 10°C rise cuts the insulation's useful life in half and a 10°C decrease doubles the insulation's life. The insulation classes for electrical machines are defined in IEC 60085 – Electrical Insulation – Thermal Evaluation and Designation. That standard sets out the thermal classifications (Class A, B, F, H, etc.) and their maximum permissible operating temperatures.

Depending on where the motor is going to be used, Class B should be sufficient for 95% of the applications. There are some applications such as ABS motors or Power closure motors that require Class H insulation but these are the exception to the rule.

| Insulation System Class | Maximum Hot Spot Temperature |

| A | 105 °C |

| B | 130 °C |

| C | 155 °C |

| D | 180 °C |

What is UL 1446 Testing?

UL 1446 is a certification standard developed by Underwriters Laboratories (UL) to qualify electrical insulation systems such as those found in motors, generators, and transformers. These systems rely on a combination of many different materials—magnet wire, resins, tapes, epoxy powders, and more—that must all work together under electrical and thermal stress.

The performance of a single material on its own does not guarantee that the full system will pass UL 1446. For instance, an epoxy coating powder may demonstrate excellent dielectric or thermal properties in its datasheet, but once it is applied to an armature, its effectiveness depends on multiple factors. The composition of the powder, its adhesion to the stator, the material of the stator itself, the thickness of the coating, and its interaction with other components all influence the outcome.

Testing an individual powder can provide a general indication of how it behaves under stress, yet system-level testing is what ultimately determines compliance. UL 1446 does not certify isolated materials; it certifies the reliability of the entire insulation system as a whole. This is why a strong performance claim, even when backed by datasheet results, is not equivalent to UL certification.

Read more about UL 1446 Testing for Epoxy Coating Powders.

Application - Epoxy Coating Powder for Slot Insulation

An electric motor is made by wrapping an electric current around a magnetic core, and these two must be insulated from each other. This can be done in two ways: (1) Using slot liners and plastic casting; (2) Using insulating epoxy coating powder. Compared with slot liners and plastic casting method, epoxy coating powders owns the advantages of efficiency and reliability as:

- Allows to use up to 25% more copper wire, making the motors 15%~20% more efficient.

- Provides a more even consistent distribution, which improves the balancing, efficiency and life time of the motors. It also makes it much quieter.

- Epoxy powders is 10 times more conductive than air, which dissipates more heat from the motor, increasing operating lifetime.

Great Performance

- Excellent edge coverage

- High cut through resistance temperature (minimum 300°C)

- High service temperatures and insulation class

- Capability to provide a range of thermal conductivities

Great Manufacturing Productivity

- High build rate enables faster coating line speed

- Outstanding adhesion to metal and plastics

- Low thickness required to achieve max performance

- Both induction and oven cure chemistries

Properties Matrix Of Epoxy Coating Powders

While selecting epoxy coating powder solutions for your motor application, there are many properties we may take into consideration. Some key properties include:

Dielectric Strength

Good dielectric strength saves material, allows to reach same breakdown voltage with less material.

Flow

Flow around 20mm means: Easy to apply during production, able to cover hard to reach parts of the motor and consistent and even coverage.

Short Cure Time

A short cure time at lower temperatures ensures increases productivity.

LINQSOL Epoxy Coating Powders are thermosetting powders designed to provide electrical insulation, mechanical protection, and environmental resistance to a wide range of components. These powders are based on epoxy resins that, when applied and cured, form a tough, uniform coating. The curing process crosslinks the resin, giving the final coating excellent dielectric strength, adhesion, and resistance to heat and chemicals.

Featured Products

- Class B (130°C) Thermal Insulation

- 25 kV/mm Breakdown Voltage

- Class F (155°C) Thermal Insulation

- 30 kV/mm Breakdown Voltage

Key Features and Benefits of LINQSOLTM Epoxy Coating Powders

- Low specific gravity, which means a reduced amount of powder needed

- Optimal stick point temperature that reduces material build-up across multiple shifts, minimizing cleaning time

- High edge coverage, which means no failure in corners

- A high cut through resistance that passes automotive requirements and protects from coil windings, even at high temperatures

- A longer shelf life at higher temperatures saves storage and transport costs.

Frequently Asked Questions about Epoxy Coating Powders

Paper inserts rely on physical layers, which can leave small gaps, are less resistant to vibration and moisture, but offer better thermal conductivity and are cheaper for simple designs. Epoxy is more suitable for automated, high-reliability applications, while paper inserts remain common for lower-cost or straightforward slots.

How is ECP applied to motor armatures?The powder is typically applied using methods such as fluidized bed dipping or electrostatic spraying. In the fluidized bed process, particles are suspended in a gas stream, creating a “fluid-like” state that allows the coating to evenly cover the copper windings. After application, the coated armature is cured at elevated temperatures, which solidifies the powder into a continuous, durable insulating layer. Proper control of particle size, airflow, and curing conditions is essential to achieve consistent and high-quality insulation.

By forming a thin, uniform insulation layer, epoxy coating powder allows more copper to be packed into each slot compared to traditional slot liners. Higher copper fill reduces electrical resistance and improves the motor’s power density, resulting in increased efficiency. Additionally, improved thermal conductivity from the coating helps dissipate heat more effectively, maintaining performance and reducing energy losses during operation. Increased uniformity also leads to decreased vibration, which increases the efficiency of the motor.

What should I consider when selecting an ECP for my motor armature application?Key factors include dielectric strength, thermal class, and coverage quality. Dielectric strength ensures the insulation can withstand operating voltages without breakdown, while thermal class determines the temperature range the coating can handle. Edge coverage and uniformity are also important to prevent weak spots that could lead to partial discharges. Additionally, application method compatibility and environmental considerations, such as halogen content, may influence the selection of the most suitable epoxy powder for a given motor design.

Featured Presentation: CAPLINQ Product Offerings

CAPLINQ Materials for Motor Armatures

Curious about how the right materials can improve motor armature performance? This quick presentation walks you through CAPLINQ’s lineup for Epoxy Coating Powders: what they’re made of, how they perform, and where they fit best. Whether you’re optimizing for efficiency, durability, or both, these materials are engineered to keep up.

Got questions or need help choosing the right epoxy coating powder for your motor armatures? Reach out to us!

Contact Us →Presentations

Types of Low-Temperature Electrolyzers

This presentation introduces the main types of low-temperature electrolyzers—systems that operate below 150 °C and are widely used for green hydrogen production. It covers the core technologies, including alkaline, PEM, and AEM electrolyzers, and highlights their operating principles, key materials, benefits, and challenges.

Related Blogs

Epoxy Coating Powders for Motor Armature Slot Insulation

This blog explores the use of epoxy coating powders for motor armature slot insulation. It explains how these powders create a protective barrier between steel laminations and copper windings, improving copper fill, heat dissipation, and motor efficiency. The blog also highlights key factors to consider, such as dielectric strength, thermal performance, and coverage, for optimal motor reliability and lifespan.

Fluidized Bed for Epoxy Coating Powders

This blog discusses the fluidized bed process for applying epoxy coating powders, commonly used in motor armature slot insulation. It explains how finely ground powder particles are suspended in a gas flow, creating a fluid-like state that allows for uniform coating of components.

What are Halogen-free Epoxy Coating Powders?

This blog explains halogen-free epoxy coating powders and their environmental benefits. It covers why halogens in flame retardants can produce toxic by-products, how certain applications may not require flame retardants, and the relevant standards defining halogen-free materials.