PTFE Tapes

PTFE Film, PTFE Tape and Generic Teflon® Products

CAPLINQ is proud to offer its own LINQTAPE™ PTFE-Series brand of high-performance, flexible, skived PTFE films with silicone adhesives for a range of applications.

High Performance Skived PTFE Tape and Film

LINQTAPE™ PTFE-Series tapes typically come in 33 meter (36 yard) length rolls of varying widths. and the base Polytetrafluoroethylene film (backing) thickness range is between 1-mil (25µm) and 5-mil (125µm) thick. Other widths, lengths and thicknesses may be available upon request.

PTFE3S | 3-mil Skived PTFE Tape with Silicone Adhesive

- 3 mil Skived PTFE film

- Silicone adhesive

- >9500V breakdown voltage

- 2 weeks

PTFE5S | 5-mil Skived PTFE Tape with Silicone Adhesive

- 5 mil Skived PTFE film

- Silicone adhesive

- >13000V breakdown voltage

- 2 weeks

PTFE2S | 2-mil Skived PTFE Tape with Silicone Adhesive

- 2 mil Skived PTFE film

- Silicone adhesive

- >7500V breakdown voltage

- In stock

Product Selector Guide

| Product name | Description | Adhesive type | Adhesive thickness | PTFE thickness | Total thickness | Peel Strength (N/25mm (oz/in)) | Breakdown voltage |

|---|---|---|---|---|---|---|---|

| PTFE2S | 2-mil Skived PTFE Tape with Silicone Adhesive | Silicone | 1.5mil (38µm) | 2mil (50.8µm) | ±3.5mil (89µm) | 7 (25) | >7,500V |

| PTFE3S | 3-mil Skived PTFE Tape with Silicone Adhesive | Silicone | 1.5mil (38µm) | 3mil (76.2µm) | ±4.5mil (114.3µm) | 7 (25) | >9,500V |

| PTFE5S | 5-mil Skived PTFE Tape with Silicone Adhesive | Silicone | 1.5mil (38µm) | 5mil (127µm) | ±6.5mil (165µm) | 7 (25) | >13,000V |

Frequently Asked Questions

FREQUENTLY ASKED QUESTIONS ABOUT PTFE TAPES

What are PTFE tapes used for?

Some of the most common applications for PTFE tapes include:

- Heating panels

- Electrical insulation

- Thermal insulation

- Wrapping and connecting high-voltage cables

- Bellows and hose liners

- Tank and vessel lining

- Slide bearings

What is PTFE and why is it a good choice for tapes?

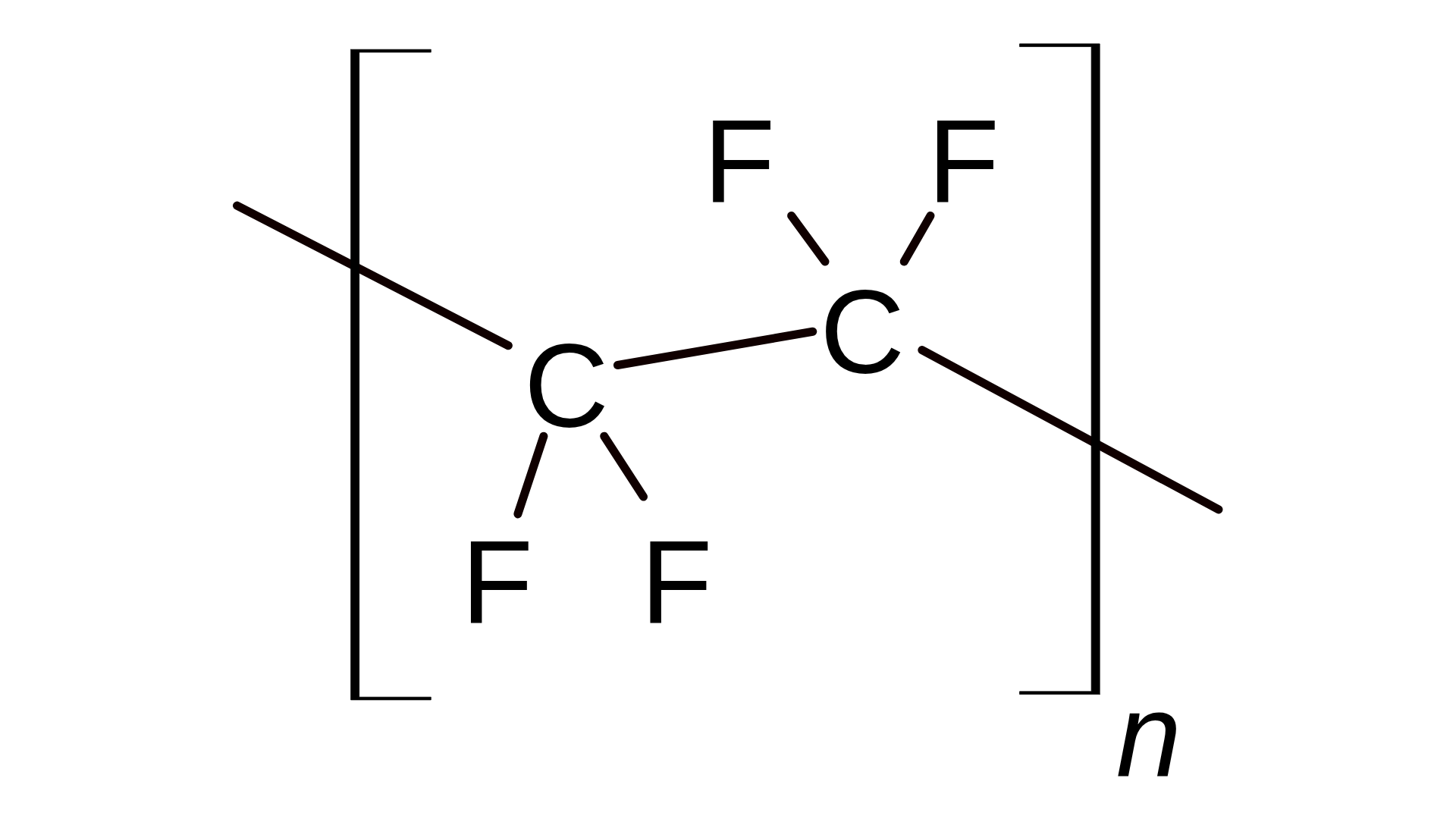

PTFE stands for Polytetrafluoroethylene. It is a fluorocarbon solid polymer, made up of carbon and fluorine. PTFE's durability, chemical and temperature resistance, and electrical insulation properties allow for versatility in applications and uses.

Learn More

PTFE Tapes

When talking about polytetrafluoroethylene (PTFE) or more commonly known as Teflon tapes, there are two general types of tape that are associated with the name: regular Teflon tapes and skived PTFE tapes.

The former is produced through extrusion and is commonly used for home improvements. On the other hand, skived PTFE tapes are produced by thinly and uniformly slicing layers of Teflon from a larger, bulkier block of the material.

From its name alone, skived PTFE tape is made up of two elements: carbon and fluorine. It is a polymer consisting of long chains of repeating units (also called monomers) of carbon and fluorine, which have a strong polar covalent bond (i.e., they “share” electrons). The bond between carbon and fluorine is so strong that they refuse to bond with other elements.

Additionally, there are two types of forces present in bulk materials, especially in the context of polymers: adhesive and cohesive forces.

Cohesive Forces

Collectively refer to intermolecular forces between the molecules that resist separation. If a stronger cohesive force is present between polymer chains, they are more likely to resist separation and remain bundled up together.

Adhesive Forces

Refer to the attractive forces between unlike substances, which then disrupt the cohesion between “like” polymer chains.

Long chains of PTFE, when bundled up together, have strong cohesive forces. The strong bonding between carbon and fluorine also makes the material have significantly low surface energy and adhesion forces with, virtually, anything that comes into contact with it. In simpler terms, the bond between carbon and fluorine are so strong that they don't want to bond with anybody else. This makes PTFE the ideal polymer for applications requiring materials that are chemically inert, low friction, and non-stick.

Listed below are the desired properties of skived PTFE tapes that make them suitable for several applications:

- High heat and chemical resistance

- Excellent electrical insulator (high dielectric strength, high surface resistivity, and resistance to electrical breakdown)

- Significantly low coefficient of friction

- Non-stick surface

When selecting the right skived PTFE tape, the following properties should be considered in relation to the intended application:

- Thickness - affects other properties such as strength and flexibility

- Width

- Adhesive type & thickness

- Peel strength

- Breakdown voltage

Skived PTFE tapes are typically used for the following applications:

- Creating a non-stick surface on rollers and belts of industrial machines that usually handle tacky and sticky materials such as adhesives.

- Protection for wires against the elements, especially those exposed to extreme heat.

- It can also be used as mold release for composite molding.

- PTFE tapes can also protect surfaces against corrosive chemicals since the material is considered as chemically inert.