KESTER TSF-6852 Tacky Soldering Flux

- 8-hour stencil life

- Leaves bright and shiny joints

- ORH1 per J-STD-004

Product Description

KESTER TSF-6852 is a synthetic water-soluble tacky soldering flux. The synthetic ingredients eliminate naturally occurring raw materials typically found in fluxes. This maximizes lot-to-lot consistency. TSF-6852 is room temperature stable and does not require refrigeration for long-term storage. This reduces production line space for material storage and the cost of refrigerated storage. TSF-6852 has been formulated to be a drop in replacement for a variety of metallurgies including low melting point alloys, typical tin-lead eutectic alloys and the higher melting point, lead-free alloys. TSF-6852 is classified as ORH1.

Product Key Features

- 8-hour stencil life

- Room temperature long-term storage

- Residue removal by water

- ORH1 for reliable performance standards.

Applications

- Soldering applications in electronics assembly requiring tacky flux.

Technical Specifications

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 220000 mPa.s |

Additional Information

Application

TSF-6852 is designed for stencil/screen printing, pin transfer, dot dispensing and/or syringe applications. Tacky solder flux formulations can be used as a tack and flux vehicle for soldering components to a solid solder deposit (SSD), or precision pad technology (PPT) board surfaces. Great for rework applications on all PCB packages. Can be used in BGA/PGA sphere/pin attachment vehicle or for repair and reballing/repinning.

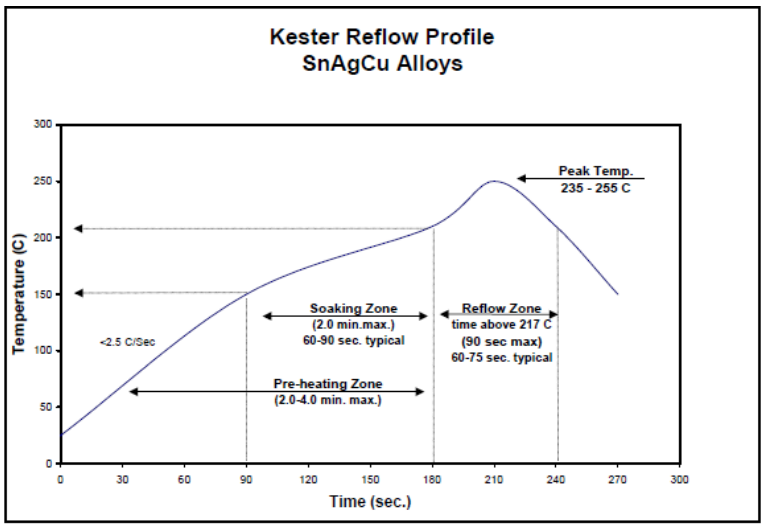

Recommended Reflow Profile

The recommended convection reflow profile for Sn96.5Ag3.5, Sn99.3Cu0.7, or the various SnAgCu alloys is shown here. This profile is simply a guideline. As TSF-6852 was engineered to be a versatile, robust interconnect material other reflow profiles will be effective. The optimal profile for a process may be different from the one shown based on oven type, component design, fixturing and mix of defects. Please contact Kester Technical Support if additional profiling advice is needed. TSF-6852 will facilitate excellent wetting in an air reflow environment and can also be used in an inert (nitrogen) environment.