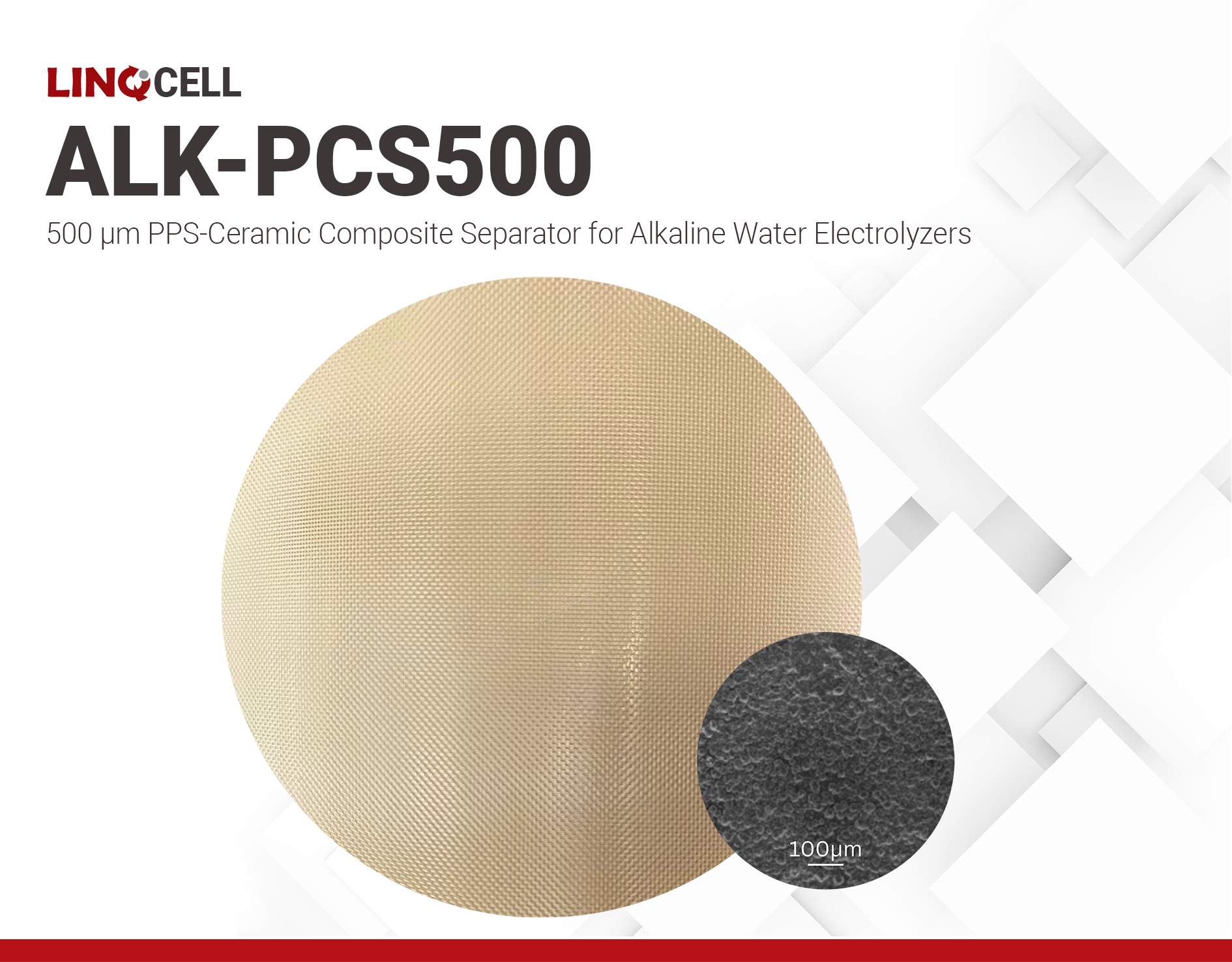

LINQCELL ALK-PCS500

- Low internal resistance

- High gas barrier properties

- Optimized separator for large-scale and high-pressure alkaline water electrolyzers

Product Description

LINQCELL ALK-PCS500 is a composite made of a polyphenylene sulfide (PPS) mesh matrix reinforced with a ceramic nano coating. The polymeric matrix provides high strength and high-pressure resistance from its sponge-like pore structure. The ceramic coating adds hydrophilicity, which improves water management during electrolysis. Additionally, the polymeric binder with nanopores in the dense coating enhances gas barrier properties, preventing gas crossover and mixing during operation. ALK-PCS500 features low internal resistance, excellent gas barrier properties, and a high bubble point pressure.

Key Features:

- Enhanced Water Management: The ceramic nano coating on the PPS mesh matrix provides hydrophilicity, improving water management within the electrolyzer and contributing to efficient electrolysis.

- Superior Gas Barrier Properties: The polymeric binder with nanopores in the dense coating minimizes gas crossover and mixing, improving the efficiency and safety of the electrolyzer.

- High Strength and Pressure Resistance: The PPS mesh matrix with its sponge-like pore structure provides high mechanical strength and pressure resistance, making the separator suitable for high-pressure alkaline water electrolyzers.

As an electrolyte separator for alkaline water electrolyzers, LINQCELL ALK-PCS500 offers significant advantages over conventional market solutions. It can also be stored dry for up to 15 days, adding to its practical usability. Overall, LINQCELL ALK-PCS500 is an ideal choice for large-scale (1000 Nm3/h) and high-pressure alkaline water electrolyzers.

Highly Recommended for:

- Alkaline water electrolyzers, particularly for large-scale and high-pressure applications.

LINQCELL ALK-PCS500 is available in rolls with a maximum width of 210 cm. Contact us for custom sizes or other specific requirements.

Technical Specifications

| General Properties | |

| Porosity Porosity Void fraction is a measure of the void spaces in a material | 55 % |

| Total Thickness Total Thickness Total thickness is taking into account all the films, coatings, adhesives, release liners and special layers and is the maximum thickness of a film or tape. | 500 μm |

| Thermal Properties | |

| Operating Temperature | 110 °C |

Additional Information

LINQCELL ALK-PCS500 Key Material Properties

| Property | Value | Unit |

|---|---|---|

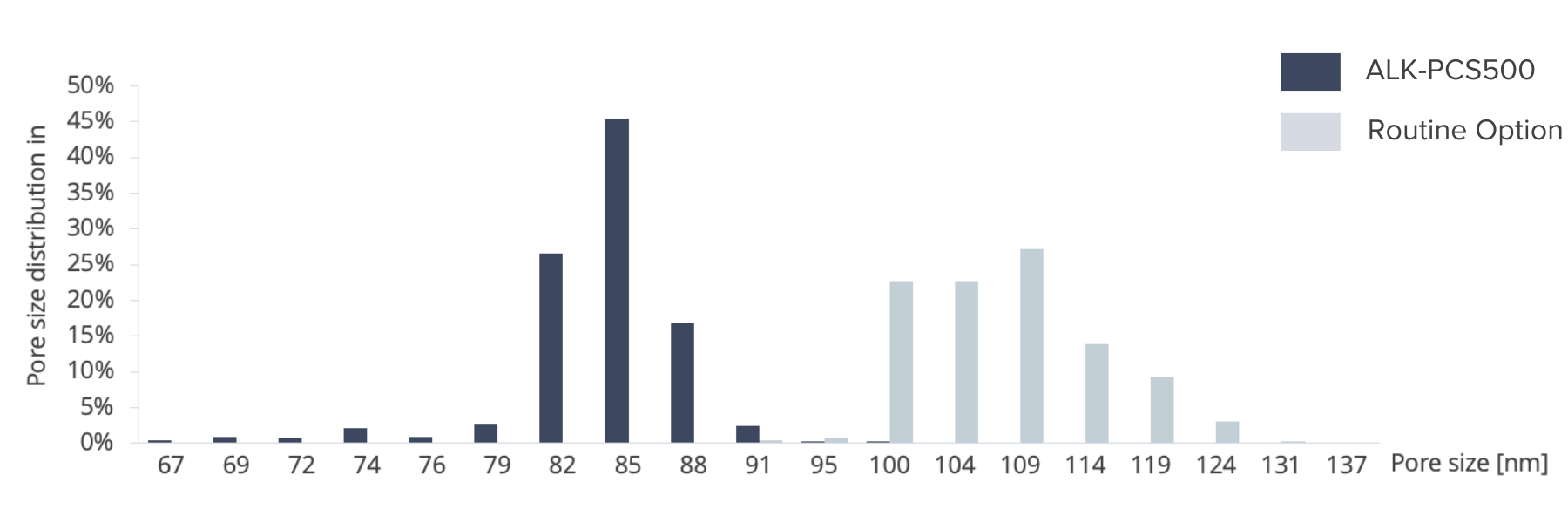

| Average Pore Diameter | <150 | nm |

| Maximum Pore Diameter | 200 | nm |

| Bubble Point | 3–5 | bar |

| Area Specific Resistance at 80 °C, 30% KOH | ≤0.15 | Ω·cm² |

- High Bubble Point — Minimizes gas crossover under high ΔP.

- Small, Uniform Pores — Consistent ion transport for stable, efficient operation.

- High Peel Strength — Excellent adhesion and mechanical integrity for long life.

- Cost Reduction — Stable performance with lower overall system cost.

Smaller and More Uniform Pores Deliver Balanced Gas Barrier Performance and Moisture Retention

Smaller, uniform pores minimize H₂/O₂ crossover to preserve gas purity and safety while retaining electrolyte for continuous ion transport. This prevents drying and supports stable, long-term electrolyzer operation.

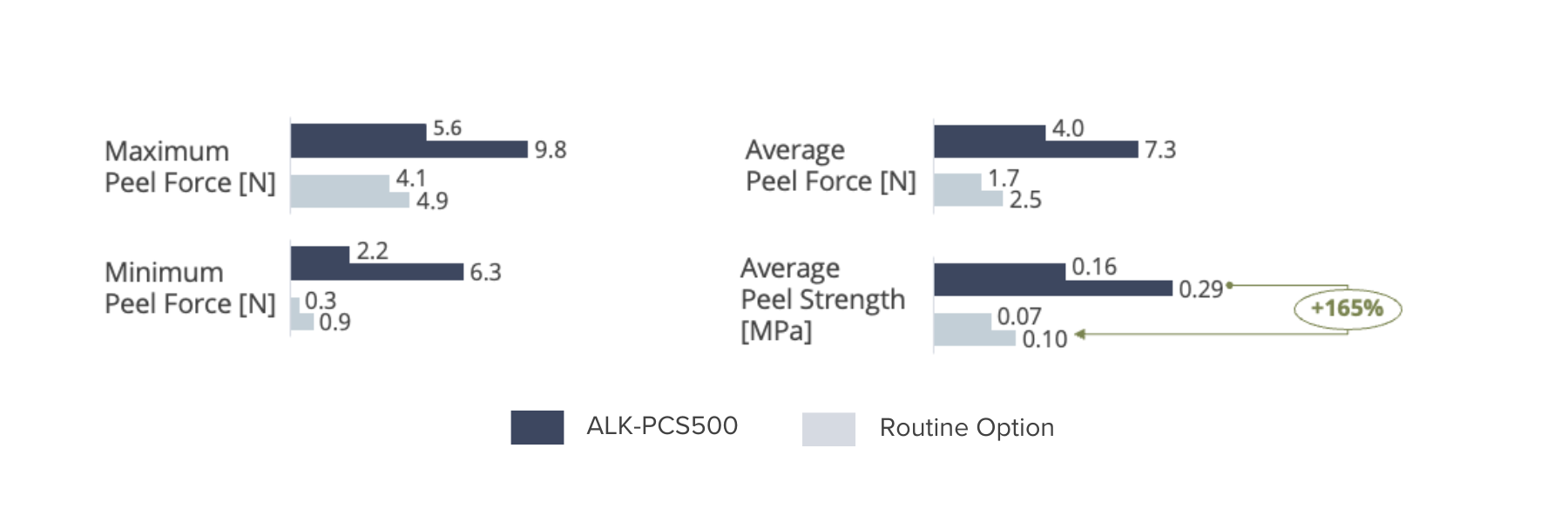

High Peel Strength Ensures Long-Term Separator Integrity

ALK-PCS500 achieves 0.29 MPa peel strength — about a 165% improvement over a routine membrane — helping maintain the gas-tight layer and extend service life.

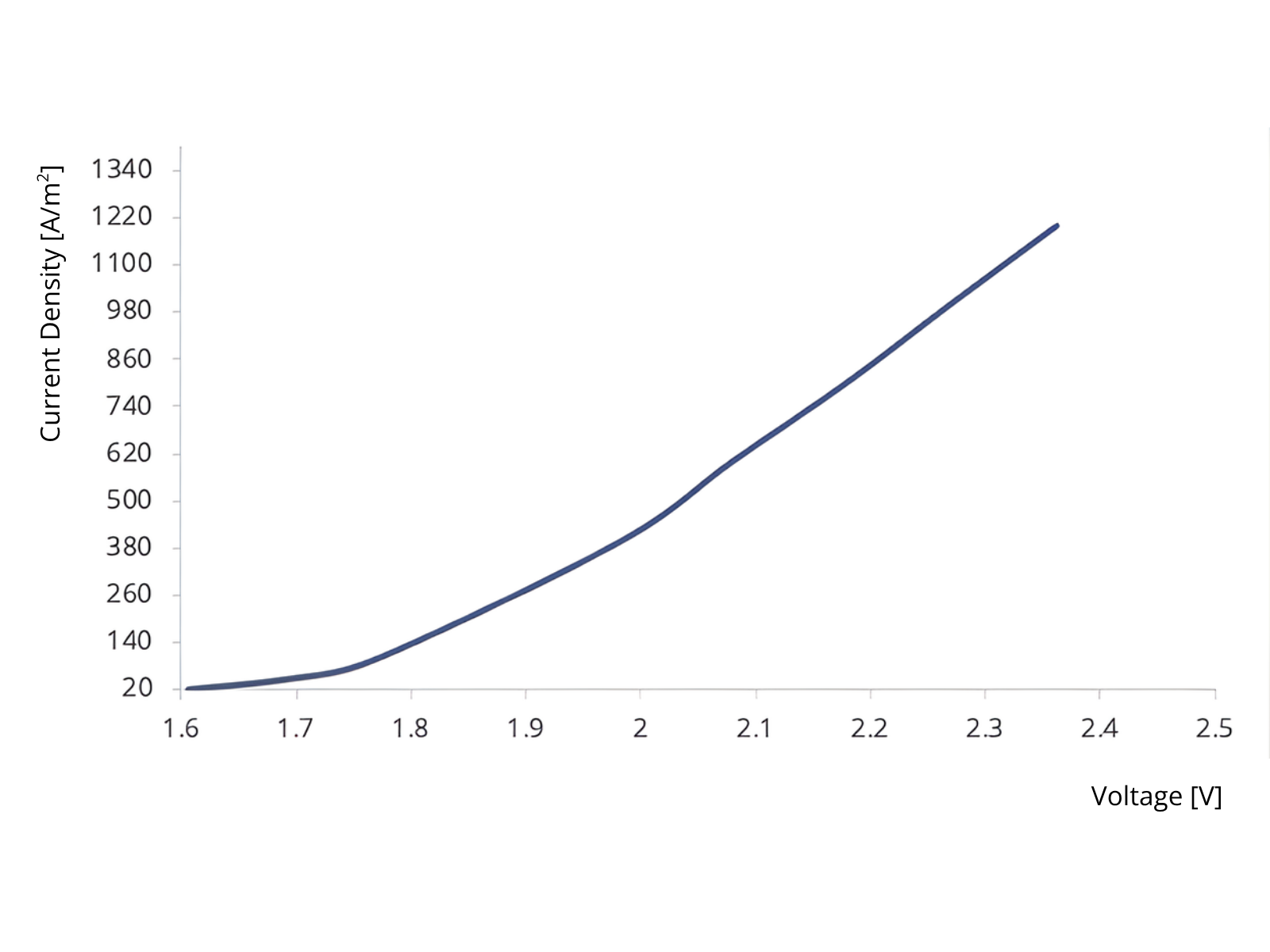

Performance in Single-Cell Alkaline Water Electrolysis

The polarization curve of ALK-PCS500 demonstrates excellent electrochemical performance under alkaline conditions (30% KOH) using a nickel mesh anode and LINQCELL CAT-NiAl cathode. ALK-PCS500 consistently operates at lower cell voltages across the current density range, confirming its low area resistance. This indicates efficient ion transport and minimal voltage loss, especially in the mid-current region, improving overall electrolyzer efficiency. Testing performed at 30 °C, 1 bar.

LINQCELL CAT-NiAl Properties (Reference)

| Property | CAT-NiAl | Test Method / Conditions |

|---|---|---|

| HER Performance | |Current| at −1.5 V > 1 A | Linear sweep voltammetry (−1.5 to −0.3 V vs. Hg/HgO) |

| Mechanical Stability | Weight loss < 1% | Ultrasonication (120 W, 60 min) |

| Electrochemical Stability | Performance decay < 2% | Cyclic voltammetry (−1.5 to −0.3 V vs. Hg/HgO, 200 cycles, 30% KOH, 30 °C ± 1) |

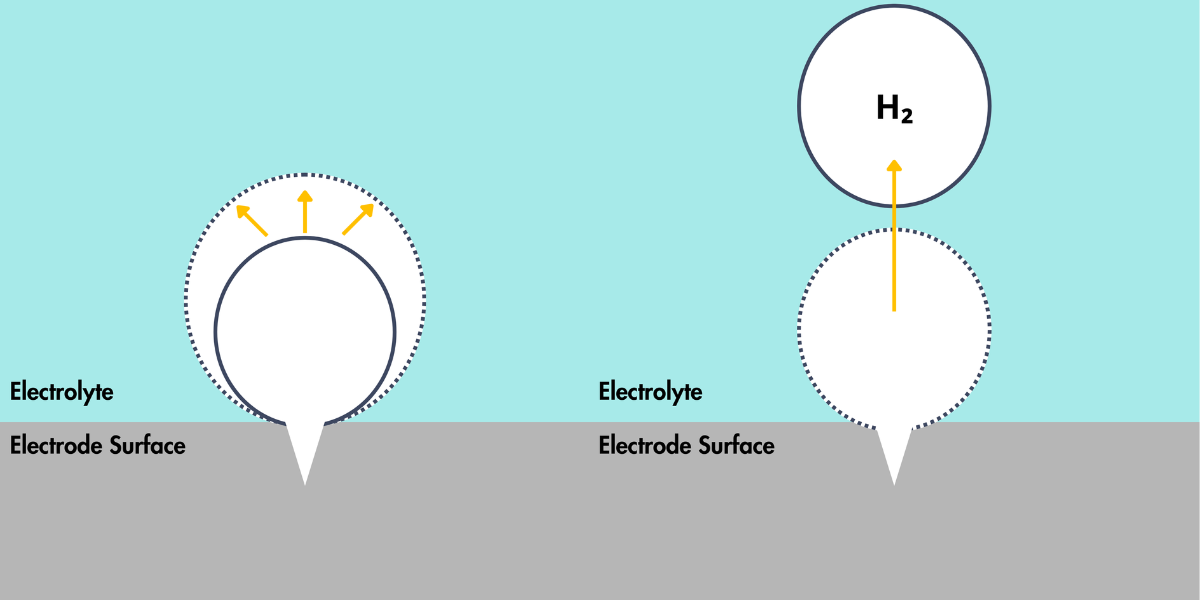

During alkaline water electrolysis, gas bubbles continuously form at the electrode surfaces and interact with the separator. These bubbles can accumulate within or near the separator pores, increasing local resistance and impeding ion transport. Prolonged bubble adhesion may also cause mechanical stress on the separator surface, leading to gradual degradation or delamination in poorly bonded materials.

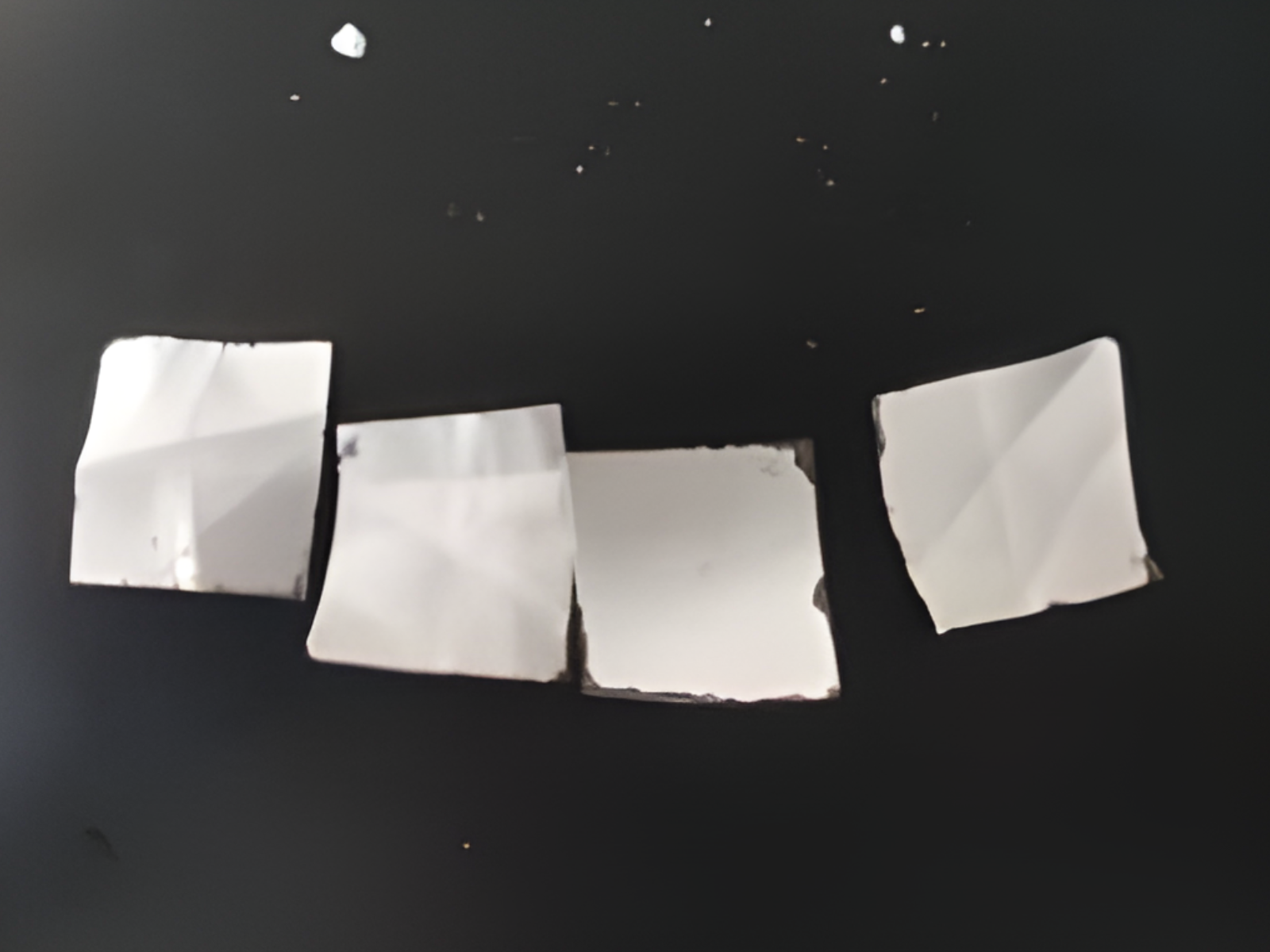

The integrity of ALK-PCS500 was evaluated under simulated gas bubble conditions using ultrasonication. Samples were exposed to 30% KOH at 80 °C, with 120 W ultrasonication for 10 hours and 300 W for 4 hours to replicate the mechanical and chemical stress caused by gas bubble formation during alkaline water electrolysis.

ALK-PCS500 maintained its structural integrity with no visible delamination or coating damage, confirming its strong adhesion and durability under harsh operating conditions.

Separator Integrity at Elevated Temperatures

Separators in alkaline water electrolyzers are often exposed to elevated temperatures during different stages of use—from drying before cell assembly to prolonged operation in hot, concentrated alkaline environments. These conditions can lead to thermal shrinkage, warping, or loss of mechanical strength in conventional polymer-based membranes.

To replicate these high-temperature conditions, ALK-PCS500 was subjected to dry compression at 85 °C for 10 hours and boiling at 30% KOH for 10 hours.

| Simulated Condition | Test Condition | ALK-PCS500 Post-test |

|---|---|---|

| Membrane drying prior to sealing installation | Dry compression at 85 °C for 10 h | No detachment or cracking on bending |

| High-temperature electrolysis under harsh alkaline environment | Boiling in 30% KOH for 10 h | No detachment or cracking; properties intact

|