This blog explains that the performance of polyimide (Kapton) tape across extreme temperatures is determined by the adhesive, not the film. It compares acrylic and silicone adhesives, showing how each behaves in low and high temperatures and helping readers choose the right tape for demanding applications.

Aviation Solar Panel

TML - Total Mass Loss

% of a materials mass that evaporates when exposed to a vacuum and high temperature.

CVCM - Collected Volatile Condensible Material

The fraction of mass that evaporates from the material then condenses on a cold surface.

WVR - Water Vapor Recovered

% of water vapor released by the material under the same conditions that can condense on a a collector.

LINQTAPE™ PIT1A-LO is an amber high-temperature resistant polyimide film designed for both permanent and temporary bonding in many high-temperature applications.

| Product | Total Mass Loss (TML-WVR) | Condensed Volatiles (CVCM) | |

|---|---|---|---|

| PIT1A-LO | <1.0 % | <0.1 % | |

ASTM E 595 Standard | <1.0 % | <0.1 % |

⚡ Applications

- Electrical Insulation

- Edge protection

- Vibration damping

- Thermal Stability

- Temporary or permanent masking

✅ Advantages

✔ Low outgassing

✔ Excellent high temperature resistance

✔ Electrical Insulation

Frequently Asked Questions about Low Outgassing Tapes

What are low-outgassing tapes used for?

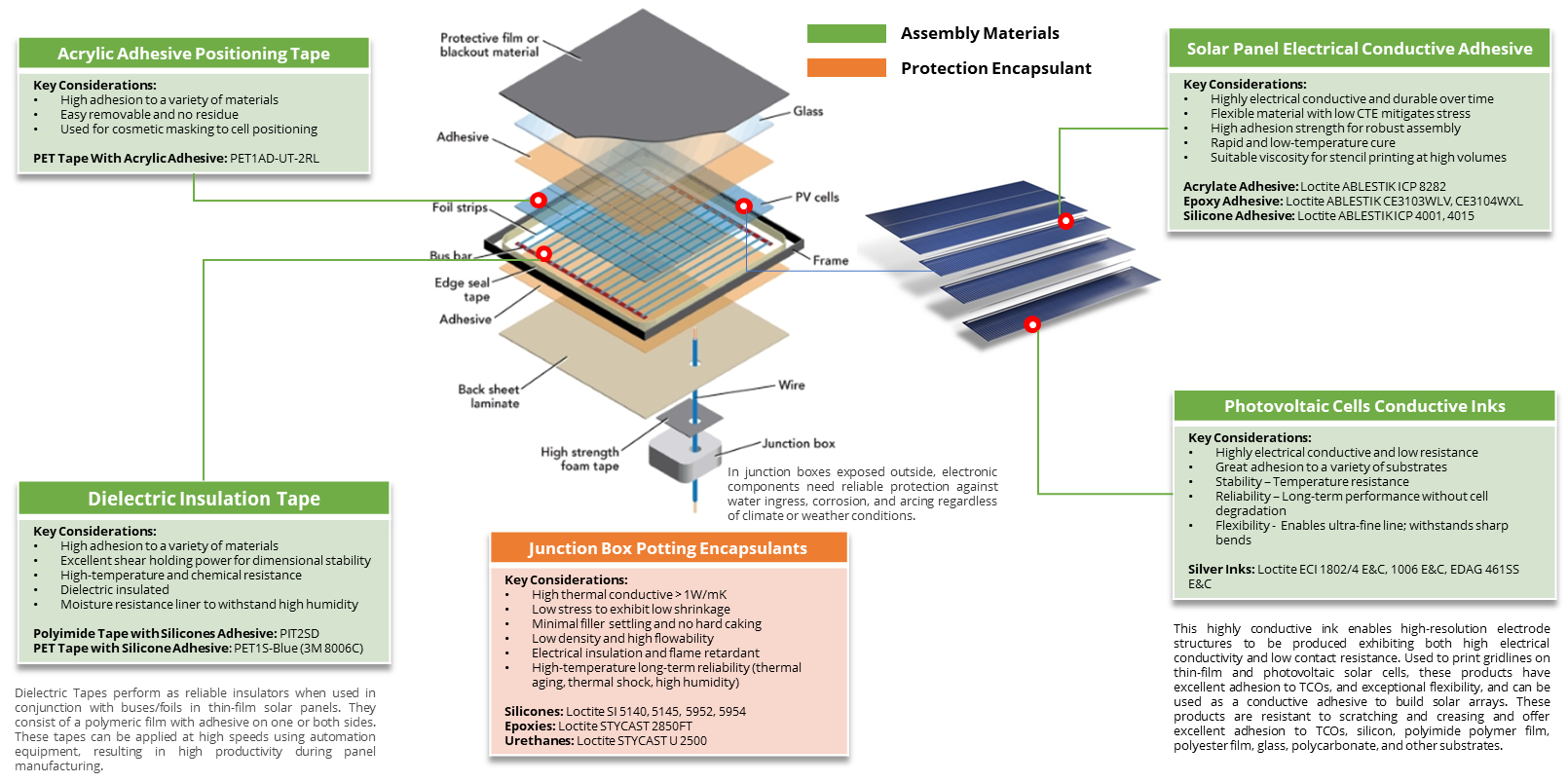

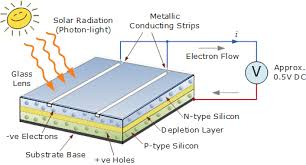

Low-outgassing tapes are used to protect sensitive components in environments where contamination from volatile compounds must be minimized. Common applications include aerospace, satellites, high-altitude aircraft, solar panels, and precision electronics. They provide electrical insulation, mechanical protection, and chemical stability without releasing gases that could compromise performance.

What specifications do I need to review when selecting a polyimide tape for an aerospace application?Aerospace outgassing tapes should have TML <1%, CVCM <0.1%, high temperature resistance (typically -70°C to 260°C), and strong adhesion without leaving residue.

What materials are used in low-outgassing tapes?

These tapes typically use high-purity polyimide (Kapton) films combined with specialized low-volatility adhesives. Both components are processed and cured to remove residual solvents and ensure long-term chemical stability.

What would happen if I used a non-outgassing tape in an aircraft solar panel?Non- outgassing tapes can release volatiles that condense on cells, reducing efficiency and damaging contacts, while low outgassing tapes ensure long-term performance.

Featured Presentation: CAPLINQ Product Offerings

CAPLINQ Materials for Specialty Tapes and Films

Curious about how the right materials can improve performance? This quick presentation walks you through CAPLINQ’s lineup for Specialty Tapes and Films.

Got questions or need help choosing the right materials for your aviation solar panels? Reach out to us!

Contact Us →Presentations

Introduction to Specialty Tapes

This presentation introduces the main types of specialty tapes and films, focusing on high-performance materials used in demanding environments. It explains adhesion properties, typical tape applications, and different industry uses, and provides guidance on how to select and use these tapes correctly to ensure optimal performance.

Related Blogs

Hydrogen Safety with Hydrogen Detection Tapes?

This blog explains how CAPLINQ’s hydrogen‑detection tapes help improve safety when working with hydrogen — a gas that’s highly flammable, diffuses quickly, and is very hard to detect because it’s colorless, odorless, and lighter than air.

Copper Foil Tape for EMI Shielding?

This blog discusses how copper foil tape is used for EMI (electromagnetic interference) shielding, static dissipation, and grounding in electronic devices. It highlights the tape’s conductive adhesive, easy application, and ability to protect sensitive circuits while improving signal integrity and device reliability.