DOWFROST LC 25 Heat Transfer Liquid

- Made with Dow PURAGUARD™ USP/EP grade PG (>99.8% purity)

- Freeze protection to –10°C (14°F)

- Formulated for high-efficiency heat transfer

Product Description

DOWFROST™ LC 25 is a ready-to-use, propylene glycol heat transfer fluid (HTF) formulated at a 25 vol% PG concentration (PG25). It contains a specialized corrosion-inhibitor package that slows oxidation commonly observed in glycol-based HTFs. The inhibitor package also stabilizes pH and reserves alkalinity, reducing corrosivity toward common system metals such as copper, brass, carbon steel, cast iron, and aluminum used in high-efficiency cooling systems.

DOWFROST™ LC 25 is made with Dow PURAGUARD™ USP/EP grade propylene glycol (>99.8% purity), which meets strict United States Pharmacopeia (USP) and European Pharmacopoeia (EP) standards. Compared with lower-grade glycols, the lower impurity content of PURAGUARD™ PG reduces the formation of degradation byproducts that lead to odor, discoloration, and shortened fluid service life, effects that corrosion inhibitors alone cannot prevent.

Key Features:

- 25% propylene glycol concentration (PG25)

- Made with Dow PURAGUARD™ USP/EP grade PG (>99.8% purity)

- Corrosion-inhibited glycol protects copper, brass, steel, cast iron, and aluminum

- Maintains pH stability and reserve alkalinity for longer fluid life

- Freeze protection to –10°C (14°F)

- Dyed fluorescent yellow-green for easy leak identification

- Formulated for high-efficiency heat transfer in industrial and data-center cooling loops

The combination of high-purity propylene glycol and optimized corrosion inhibitors makes DOWFROST™ LC 25 a chemically stable, low-impurity heat transfer fluid suitable for long-term operation in industrial and data center cooling systems.

Uses:

- Datacom and telecom equipment cooling loops

- Direct-to-chip liquid cooling for high-performance processors

- Data center thermal management and cooling systems

Technical Specifications

| Thermal Properties | |

| Boiling Point Boiling Point The amount of degree’s needed to reach in order to make the substance boil. | 101.4 °C |

| Specific Heat Capacity Specific Heat Capacity Specific heat capacity is the amount of heat energy required to raise the temperature of a substance per unit of mass. The specific heat capacity of a material is a physical property. It is also an example of an extensive property since its value is proportional to the size of the system being examined. | 3.94 J/(g⋅°C) |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 0.485 W/m.K |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 2.8 mPa.s |

Additional Information

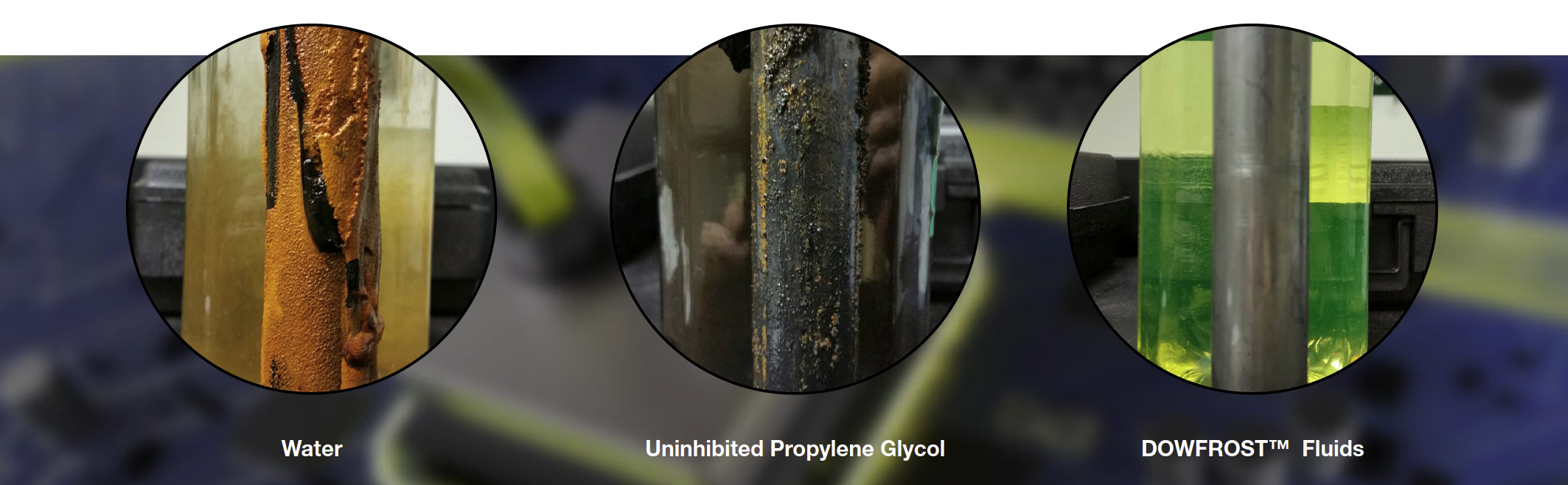

Typical values shown for reference only and should not be used as specifications. Quick takeaways How to use this table Refractive index values are reference data for concentration verification and should be measured using calibrated instruments at the specified temperatures. Long-term reliability of direct-to-chip liquid cooling systems depends on strict control of corrosion across all wetted materials. Comparative corrosion testing demonstrates that DOWFROST™ LC 25 delivers excellent corrosion protection across all metals tested , achieving orders-of-magnitude lower corrosion rates than water and uninhibited propylene glycol. Visual comparison of metal corrosion after exposure to water, uninhibited propylene glycol, and DOWFROST LC 25. Corrosion performance evaluated using ASTM D1384 testing at 190 °F (88 °C) for two weeks with constant air bubbling. Glycol solutions were prepared at 30 vol%. Corrosion rates are reported as mils penetration per year (mpy). Corrosion rates above 0.5 mpy (2.5 mpy for aluminum) generally indicate insufficient corrosion protection. DOWFROST™ LC heat transfer fluids are designed to be chemically compatible with common system metals and alloys at bulk fluid temperatures up to 90 °C (194 °F). DOWFROST™ LC 25 is formulated for long-term compatibility with common elastomers and plastics at bulk fluid temperatures up to 90 °C (194 °F). Always confirm with material suppliers for specific formulations. Compatibility ratings are qualitative and may vary by formulation and supplier. DOWFROST™ LC 25 is formulated to maintain chemical compatibility with a wide range of elastomers and plastics commonly used in liquid cooling systems operating at bulk fluid temperatures up to 90 °C (194 °F). Materials such as PTFE and FEP exhibit excellent compatibility at elevated temperatures, while EPDM, polyethylene (PE), polypropylene (PP), and polysulfone-based polymers (PSU, PPSU) are generally suitable for operation up to approximately 75 °C. Some elastomers and plastics, including NBR, silicone, polyamide (PA), polyoxymethylene (POM), and certain fluoroelastomers (FKM), may have lower recommended temperature limits or reduced long-term stability when exposed to propylene glycol–based fluids. DOWFROST™ LC 25 is a ready-to-use heat transfer fluid and should not be diluted. It is formulated with the correct concentration of corrosion inhibitors to protect datacom equipment cooling systems (DECS) and other liquid cooling loops. If dilution is unavoidable, only purified water—distilled, deionized (DI), or reverse osmosis (RO)— should be used. Minimum water quality limits for any unavoidable dilution: DOWFROST™ LC 25 contains corrosion inhibitors, pH buffers, and stabilizing additives that are intentionally added to protect metals and maintain long-term fluid performance. These additives increase ionic content, resulting in electrical conductivity values typically above 2,000 µmhos/cm. The higher conductivity is not a concern because DOWFROST™ LC 25 is used in closed-loop liquid cooling systems, where the fluid is fully contained and isolated from electronic circuits.Typical Properties and Applications of DOWFROST™ LC 25

Typical Properties

Propylene Glycol Concentration 25 vol% Freezing Point 14 °F (–10 °C) Boiling Point @ 760 mmHg 101.4 °C Specific Gravity (25/25 °C) 1.030–1.036 pH 8.0–10.5 Reserve Alkalinity >6.0 mL 0.1 N HCl Thermal Conductivity @ 50 °C 0.485 W/m·K Specific Heat @ 50 °C 4.13 kJ/kg·K Viscosity 2.72 mPa·s @ 20 °C

1.15 mPa·s @ 50 °C Volume Expansion (–10 to 90 °C) 5.1 % Sulfate Content <10 ppm Chloride Content <5 ppm Total Hardness (as CaCO₃) <20 ppm Recommended for

Propylene Glycol Concentration vs. Refractive Index and Freezing Point

PG Concentration (wt%) PG Concentration (vol%) Refractive Index (20 °C) Refractive Index (25 °C) Freezing Point (°F) Freezing Point (°C) 18 17.8 1.3542 1.3536 19.9 –6.7 19 18.8 1.3555 1.3548 19.4 –7.0 20 19.8 1.3568 1.3561 18.9 –7.3 21 20.8 1.3581 1.3573 18.1 –7.7 24 23.8 1.3618 1.3611 15.6 –9.1 25 24.9 1.3630 1.3622 14.7 –9.6 26 25.9 1.3643 1.3634 13.6 –10.2 27 26.9 1.3655 1.3646 12.6 –10.8 28 27.9 1.3667 1.3659 11.5 –11.4 29 29.0 1.3679 1.3670 10.2 –12.1 30 30.0 1.3691 1.3691 9.0 –12.8 31 31.0 1.3702 1.3693 7.7 –13.5 32 32.0 1.3714 1.3705 6.4 –14.2 33 33.1 1.3725 1.3716 5.0 –15.0 34 34.1 1.3737 1.3728 – –15.8 35 35.1 1.3748 1.3739 1.9 –16.7 Corrosion Performance of DOWFROST™ LC 25

Metal Water (mpy) Uninhibited PG (mpy) DOWFROST™ LC 25 (mpy) COPPER 0.08 0.16 0.03 SOLDER 3.14 34.70 0.04 BRASS 0.23 0.20 0.07 MILD STEEL 9.69 9.80 0.02 CAST IRON 21.20 16.20 0.02 ALUMINUM 13.20 1.80 0.31 Chemical Compatibility with Wetted Metals

Chemical Compatibility with Elastomers and Plastics

Elastomers and Plastics Compatibility with DOWFROST™ LC 25 Acrylonitrile butadiene rubber (NBR) ★☆☆☆☆ Most compositions not recommended above 40 °C Polyoxymethylene (POM) ★☆☆☆☆ Not recommended above 30 °C Ethylene Propylene Diene Monomer (EPDM) ★★★★☆ Acceptable up to at least 75 °C Fluoroelastomer (FKM) ★★☆☆☆ Some compositions not recommended above 40 °C Fluorinated Ethylene Propylene (FEP) ★★★★★ Acceptable up to at least 90 °C Polyamide (PA) ★☆☆☆☆ Most compositions not recommended above 40 °C Polychloroprene (CR) ★★☆☆☆ Some compositions not recommended above 40 °C Polyethylene (PE) ★★★★☆ Acceptable up to at least 75 °C Polyphenylene Sulfide (PPS) ★★★☆☆ Acceptable up to at least 60 °C Polytetrafluoroethylene (PTFE) ★★★★★ Acceptable up to at least 90 °C Polypropylene (PP) ★★★★☆ Acceptable up to at least 75 °C Polysulfone / Polyphenylsulfone (PSU, PPSU) ★★★★☆ Acceptable up to at least 75 °C Silicone ★☆☆☆☆ Most compositions not recommended above 40 °C Frequently Asked Questions

▶ Is DOWFROST™ LC 25 compatible with elastomers and plastics used in liquid cooling systems?

▶ Can DOWFROST™ LC 25 heat transfer fluid be diluted?

Total Chlorides (as Cl⁻) < 25 mg/L Total Sulfates (as SO₄²⁻) < 25 mg/L Total Hardness (as CaCO₃) < 50 mg/L Total Iron (as Fe) < 1 mg/L Electrical Conductivity < 50 µmhos/cm pH 5 < pH < 9 ▶ Why does DOWFROST™ LC 25 have higher electrical conductivity than purified water, and is it a concern?