Hysol GR510-HP | Black Epoxy Mold Compound

- Very low CTE of 8 ppm/°C

- High filler loading (88%)

- Designed for high power applications

Product Description

Hysol GR510 HP is a low CTE epoxy mold compound for SOP and QFP packages. It is Hysol Huawei's high performance epoxy molding compound for small semiconductor packages including resistors, Small Outline Packages (SOP), Small Outline Transistors (SOT) and Small Outline Diodes (SOD). The very high filler loading (88%) gives it a very low coefficient of thermal expansion as well as a very low moisture absorption. Packages using this epoxy mold compound have achieved JEDEC reliability of MSL 3 or better.

Hysol GR510 HP is a green, RoHS compatible material that has a proven reliability performance on SOP & QFP packages and high power integrated circuits. It exhibits excellent electrical performance even with Copper wire at high temperatures and has excellent workability with more than 300 shots continuous mold while also meeting UL94 V-0 flammability rates at 1/8 inch thickness. Its CTI, comparative tracking index value is 600V.

Technical Specifications

| General Properties | |

| Color Color The color | Black |

| Filler Content | 88 % |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 1.99 |

| Thermal Properties | |

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 116 °C |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 0.80-0.93 W/m.K |

| UL 94 Rating UL 94 Rating Flammability rating classification. It determines how fast a material burns or extinguishes once it is ignited. HB: slow burning on a horizontal specimen; burning rate less than 76 mm/min for thickness less than 3 mm or burning stops before 100 mm V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed. V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole. 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole | V0 |

| Electrical Properties | |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 2.0x1016 Ohms⋅cm |

| Chemical Properties | |

| Moisture absorption | 0.24 % |

| Physical Properties | |

| Spiral Flow @ 175°C | 101.6 cm |

| Curing Conditions | |

| Transfer Pressure | 40 - 85 kg/cm2 |

| Transfer Time | 5 - 15 s |

Additional Information

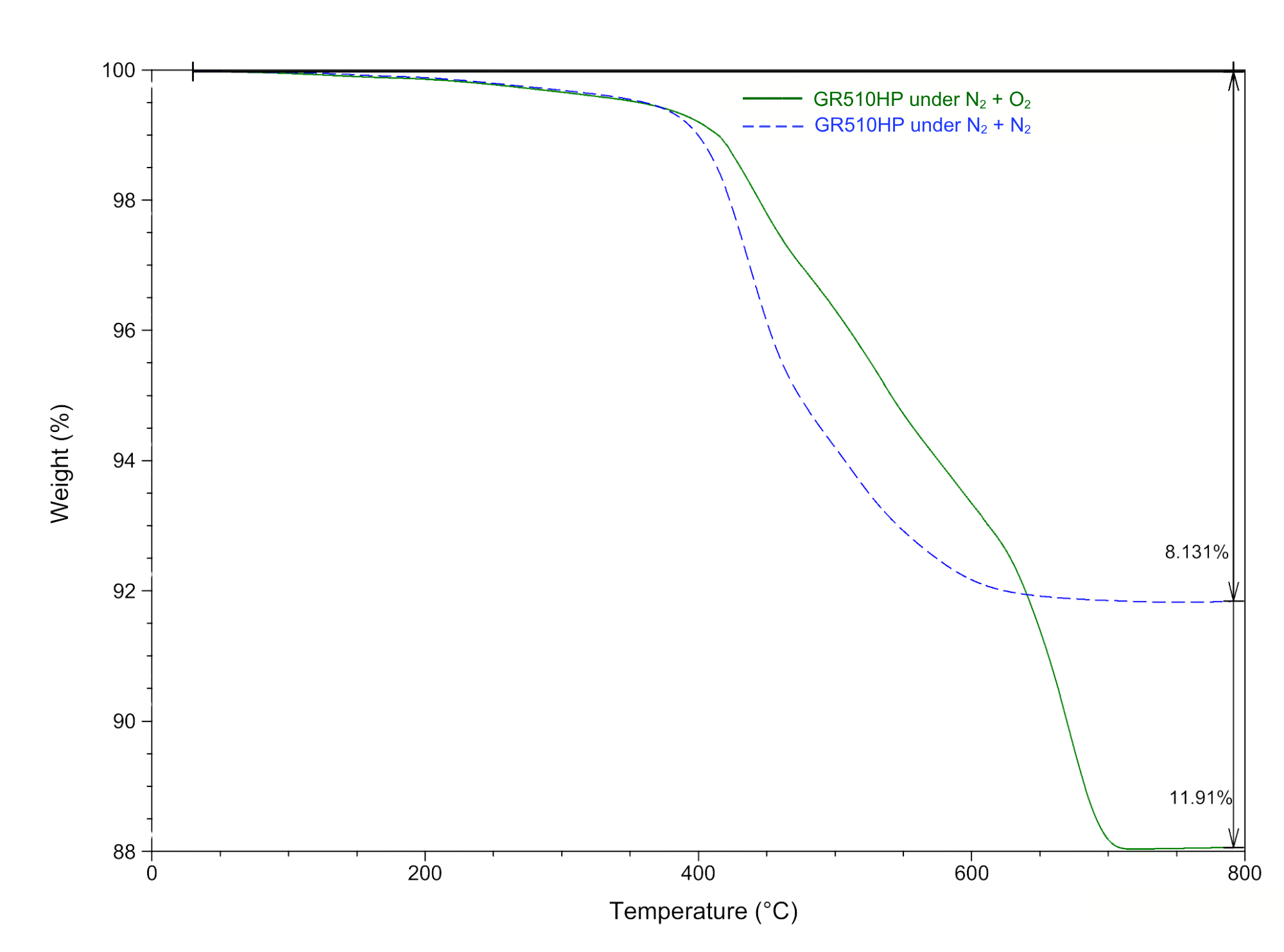

GR510HP Thermal Degradation Performance

In the oxidative environment, the degradation profile shifts slightly toward higher temperatures, with T₅% = 540 °C and T₁₀% = 668 °C, while the Tₘₐₓ (DTG) occurs at 428 °C with a slower mass-loss rate (≈ 0.000835 % / °C). This counter-intuitive rise in onset temperature is characteristic of systems where oxidative crosslinking or char consolidation temporarily delays volatile evolution. However, total mass loss increases to 11.91 wt %, and the residual ash yield decreases to 88.09 %, reflecting that oxidative cleavage ultimately consumes part of the carbonized structure. The result in the N2+O2 run is a more complete burnout of organic content/filler plus inorganic additives.

| Property | Unit | 25 °C | 150 °C | 175 °C |

|---|---|---|---|---|

| Volume Resistivity | Ω·cm | 37.6 | 0.26 | 0.01 |

| Flexural Strength | MPa | 153 | 26 | 19 |

| Flexural Modulus | MPa | 21 986 | 936 | 694 |

| Adhesion to Cu (post PMC) | N | 428 | 284 | 149 |

| Adhesion to Cu (post MSL3) | N | 358 | 225 | 139 |

| Adhesion to Cu (post PMC) | MPa | 7.41 | 4.92 | 2.58 |

| Adhesion to Cu (post MSL3) | MPa | 6.20 | 3.90 | 2.41 |

| Property | Unit | GR-510HP |

|---|---|---|

| Glass Transition Temperature (Tg) | °C | 121 |

| Coefficient of Thermal Expansion α₁ | ppm / °C | 7.5 |

| Coefficient of Thermal Expansion α₂ | ppm / °C | 30.5 |

| Dielectric Constant @ 1 MHz | – | 3.7 |

| Electrical Conductivity (oEW) | µS/cm | 20 |

| Thermal Conductivity | W/m·K | 0.93 |

| Ion Content | ||

| Chlorine (Cl⁻) | ppm | 9 |

| Sodium (Na⁺) | ppm | 4 |

| Potassium (K⁺) | ppm | 1 |

| Bromine (Br⁻) | ppm | 0 |

| Sulfate (SO₄²⁻) | ppm | 9 |

Adhesion Strength Data

| Property | Value | Unit |

| Adhesion at RT to Cu Substrate after PMC | 7.41 | MPa |

| Adhesion at RT to Cu Substrate after Preconditioning | 5.33 | MPa |

| Adhesion at RT to Cu Substrate after ML3 | 6.2 | MPa |

Electrical Properties

| Test Mode | Alternating Current | Direct Current | |

| Voltage Ramp Speed (KV/sec) | 2 | 4 | |

| Dielectric Strength (KV/mm) | GR510-HP | 14.9 | 49.0 |

| KL-G-100S | 14.0 | 28.4 | |

| Gr-360A-ST | 13.9 | 24.2 | |

Test utilized insulating oil as surrounding medium.