KESTER 186 Soldering Flux

- Approved under MIL-F-14256 as Rosin Mildly Activated.

- High thermal stability

- Excellent electrical reliability

Product Description

Kester 186 Rosin Flux is a high-performance formula developed for critical soldering applications, even on difficult assemblies, where process requirements mandate a Type RMA (Rosin Mildly Activated) flux. It meets requirements for MIL-F-14256 and provides fluxing ability approaching that of Type RA flux.

Kester 186 is engineered for reliability, possessing high thermal stability suitable for soldering multi-layer assemblies that require high preheat temperatures. Its residue offers superior electrical and environmental properties, making it acceptable for many no-clean applications.

Product Key Features

- Maintains performance and residue solubility even after exposure to high preheat temperatures for multi-layer soldering.

- Causes no surface insulation resistance (SIR) degradation.

- Non-corrosive and non-conductive.

- No-clean compatible

Applications

- Designed for use in applications where difficult assemblies must be soldered but an RMA flux type is required.

- Ideal for soldering complex multi-layer electronic assemblies requiring high preheat temperatures.

Technical Specifications

| General Properties | |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 0.879 |

| Thermal Properties | |

| Flash Point Flash Point The flashpoint of a solvent is the lowest possible temperature at which it can vaporize to form an ignitable vapor. Flashpoint is often confused with “autoignition temperature”, which is the temperature at which a solvent ignites without an ignition source. | 18 °C |

Additional Information

Flux Application

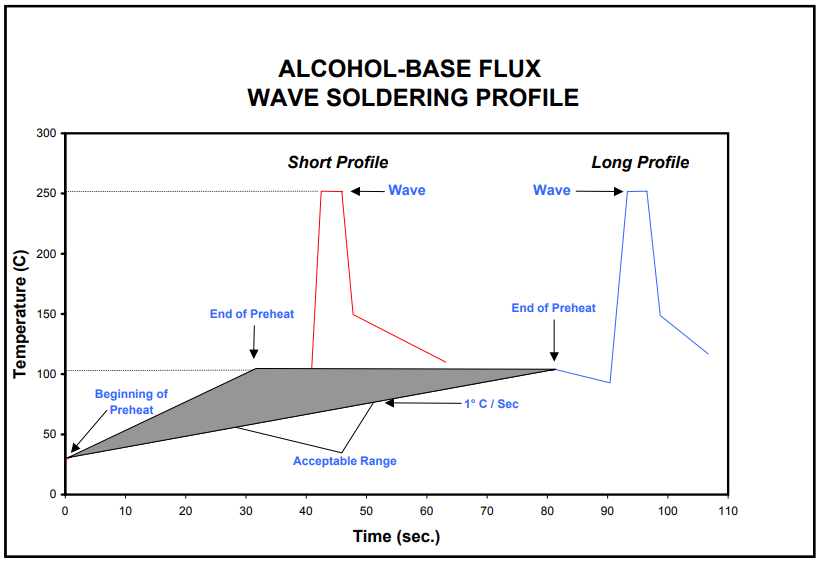

In Wave Soldering, 186 can be applied to circuit boards by a foam or dip process. An air knife after the flux tank is recommended tp remove excess flux from the circuit board and prevent dripping on the preheated surface. A spray application can be used if the spray system can handle a high solids flux (36%).