KESTER 979 Solder Flux

- Chemically compatible with most solder mask & laminates

- Does not degrade SIR

- Bellcore GR-78 Compliant

Product Description

Kester 979 is a VOC-free, no-clean flux formulated for producing high-quality, low-defect solder joints on electronic circuit board assemblies. Its advanced, finely tuned activation system delivers the best wetting performance available in VOC-free liquid flux technology, resulting in the shiniest solder joints possible.

Product Key Features

- Contains no volatile organic compounds for a safer workplace and reduced environmental impact.

- Superior wetting & joint appearance

- Leaves a minimal amount of residue after soldering, which is non-corrosive, non-conductive, and does not require removal

- Does not attack properly cured solder masks or standard FR-4 Epoxy-Glass laminate materials.

Applications

- Wave soldering & selective soldering

- Processes requiring low-residue fluxes

Note: Not compatible for use in a soldering process that does not have a preheat cycle associated with it, such as soldering with an iron.

Technical Specifications

| General Properties | |

| Solids | 4.5 % |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 1.02 |

Additional Information

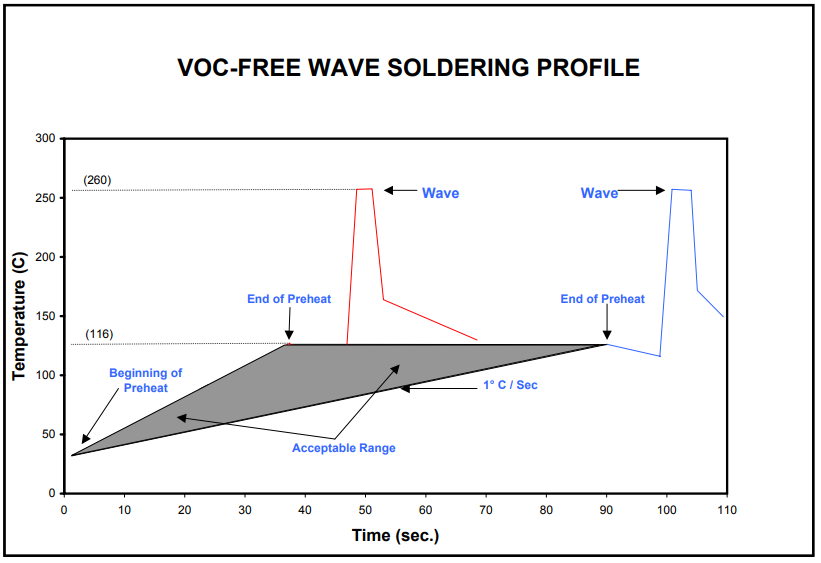

Flux Application

In Wave Soldering, Kester 979 can be applied to circuit boards by a spray, foam, or dip process. Flux deposition should be 120 to 240ug of solids/cm2 (750 to 1500ug of solids/in2). An air knife after the flux tank is recommended to remove excess flux from the circuit board and prevent dripping on the preheater surface. 979 does not work in foam application.

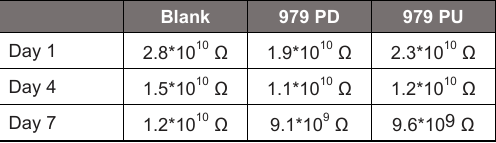

Surface Insulation Resistivity (SIR) Data