KESTER NF372-TB Soldering Flux

Harmonization Code : 29051200 | Propan-1-ol (propyl alcohol) and propan-2-ol (isopropyl alcohol)

Main features

- Provides good solderability at atmospheric temperature

- Zero-halogen & low solids formulation

- Safe for rework

Product Description

KESTER NF372-TB is a zero-halogen, no-clean, low solids liquid flux engineered for superior performance in demanding soldering operations. It's universally compatible with both leaded and lead-free alloys and is classified as ROL0 under the IPC J-STD-004B standard, ensuring minimal and safe residues.

NF372-TB Solder Flux is part of Kester’s high reliability product line and compatible with NP505-HR Solder Paste, RF550 Rework Flux and SELECT-10™ Selective Soldering Flux.

Product Key Features

- Zero-halogen & low solids

- Withstands long dwell times and high preheat temperatures

- Residues are minimal, clear, and non-tacky

- Fully compatible with a wide array of leaded and lead-free solder alloys

Applications

- Thick PCBs or applications requiring high thermal input.

Technical Specifications

| General Properties | |

| Solids | 3.90 % |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 0.793 |

Additional Information

Flux Application

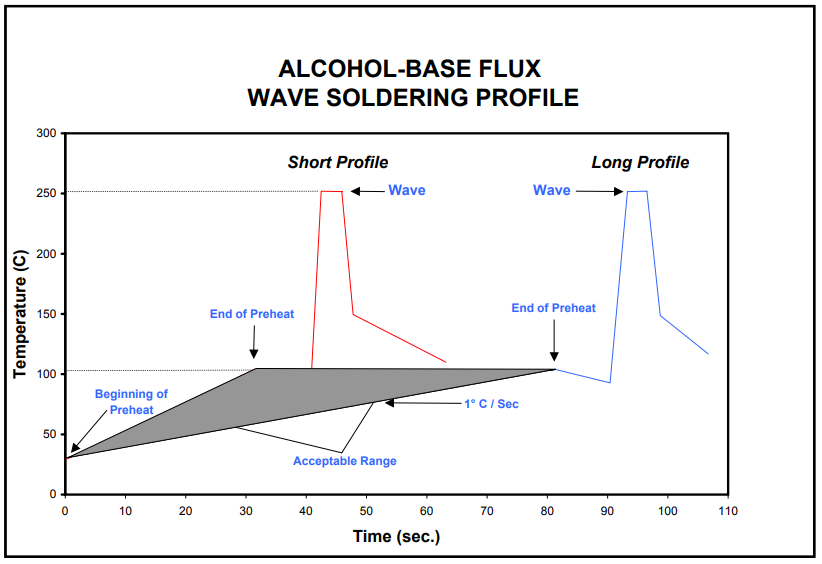

Process Parameters

| Process Parameters | Recommendation |

| Flux Deposition | 600 to 1400 ug/in2 of solids (93 to 217 ug/cm2) |

| Top Side Board Temperature (Bottom Preheaters Only) | 75 to 120℃ |

| Top Side Board Temperature (Bottom and Top Preheaters Only) | 95 to 140℃ |

| Bottom Side Board Temperature | 0 to 32℃ vs top side board temperature |

| Recommended Preheat Profile | Straight tamp to top side board temperature |

| Conveyor Speed | 0.5 to 1/2 m/min (1.6 to 3.9 ft/min) |

| Solder Contact Time | 3 to 7 seconds |

| Solder Bath Temperature | 260 to 270℃ (500 to 518℉) for SnCu or SAC alloy 245 to 260℃ (473 to 500℉) for Sn63Pb37 alloy |