Kester TSF-ULR18

- Ultra-low residue

- No-clean formulation

- High reliability

Product Description

Kester TSF-ULR18 is a no-clean, ultra-low residue tacky flux designed to meet the demands of advanced semiconductor packaging. TSF-ULR18 addresses challenges in high-density miniaturization and ultra-fine interconnect processes where flux cleaning is difficult or unnecessary.

Product Key Features

- Ultra-low residue

- No-clean formulation

- High reliability

- Optimized for fine pitch; ideal for ultra-fine copper pillar and micro-ball bump flip chip IC packages

Applications

- Flip Chip on Lead Frame, Ultra Fine Pitch Cu Pillar Bump and Micro-Solder Bump, 2.5D, 3D Packaging, Flip Chip MEMs, and others Flip Chip Packaging that do not require flux cleaning.

Technical Specifications

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 350000 mPa.s |

| General Properties | |

| Pot Life Pot Life Pot life is the amount of time it takes for the viscosity of a material to double (or quadruple for lower viscosity materials) in room temperature after a material is mixed. It is closely related to work life but it is not application dependent, less precise and more of a general indication of how fast a system is going to cure. | 24 hours |

Additional Information

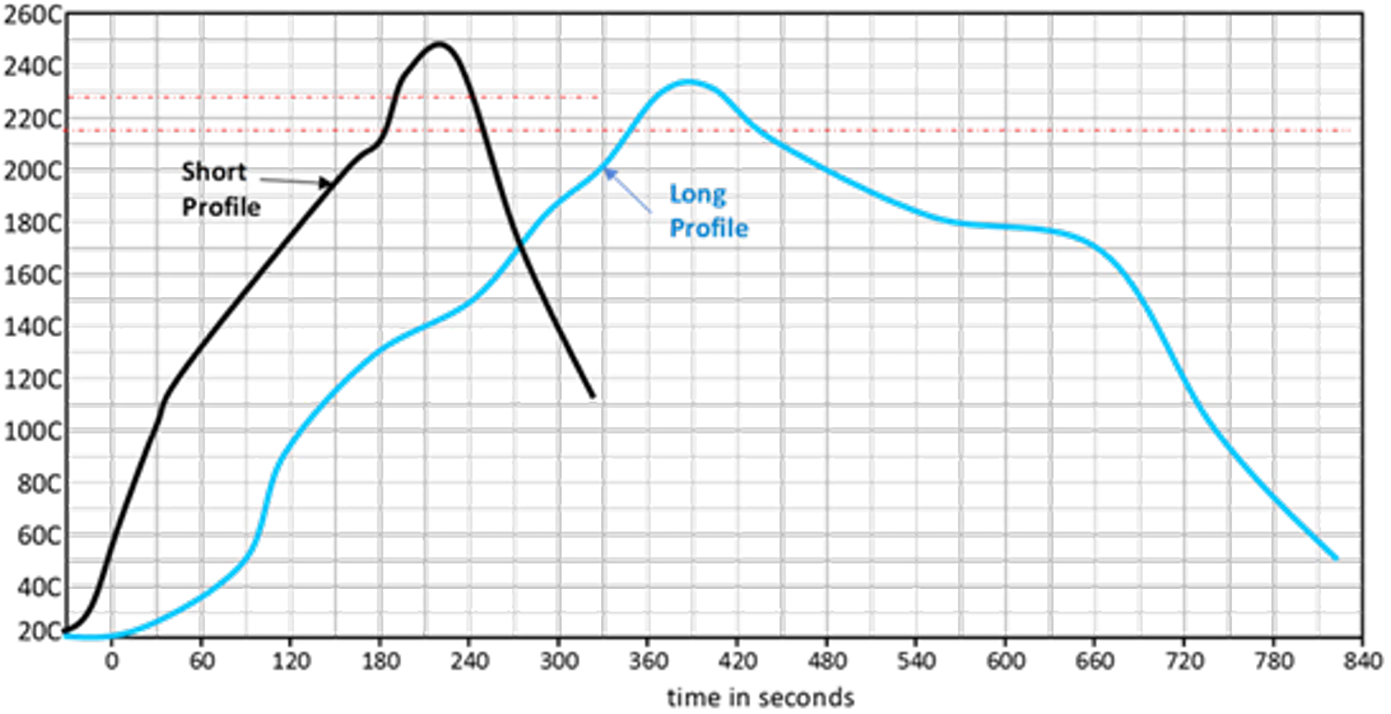

Recommended Reflow Profile

The typical convection reflow profile for TSF-ULR18 use for various lead-free alloys such as Sn96.5Ag3.5, Sn99.3Cu0.7, SnAg1.8, Sn100 and other various SnAgCu alloys is shown here. This profile is simply a guideline. TSF-ULR18 was engineered to be versatile and robust for customer reflow process. The optimal profile varies depending on device, component design, fixture, package design and device defect challenges. Please contact us if you need additional profiling advice.