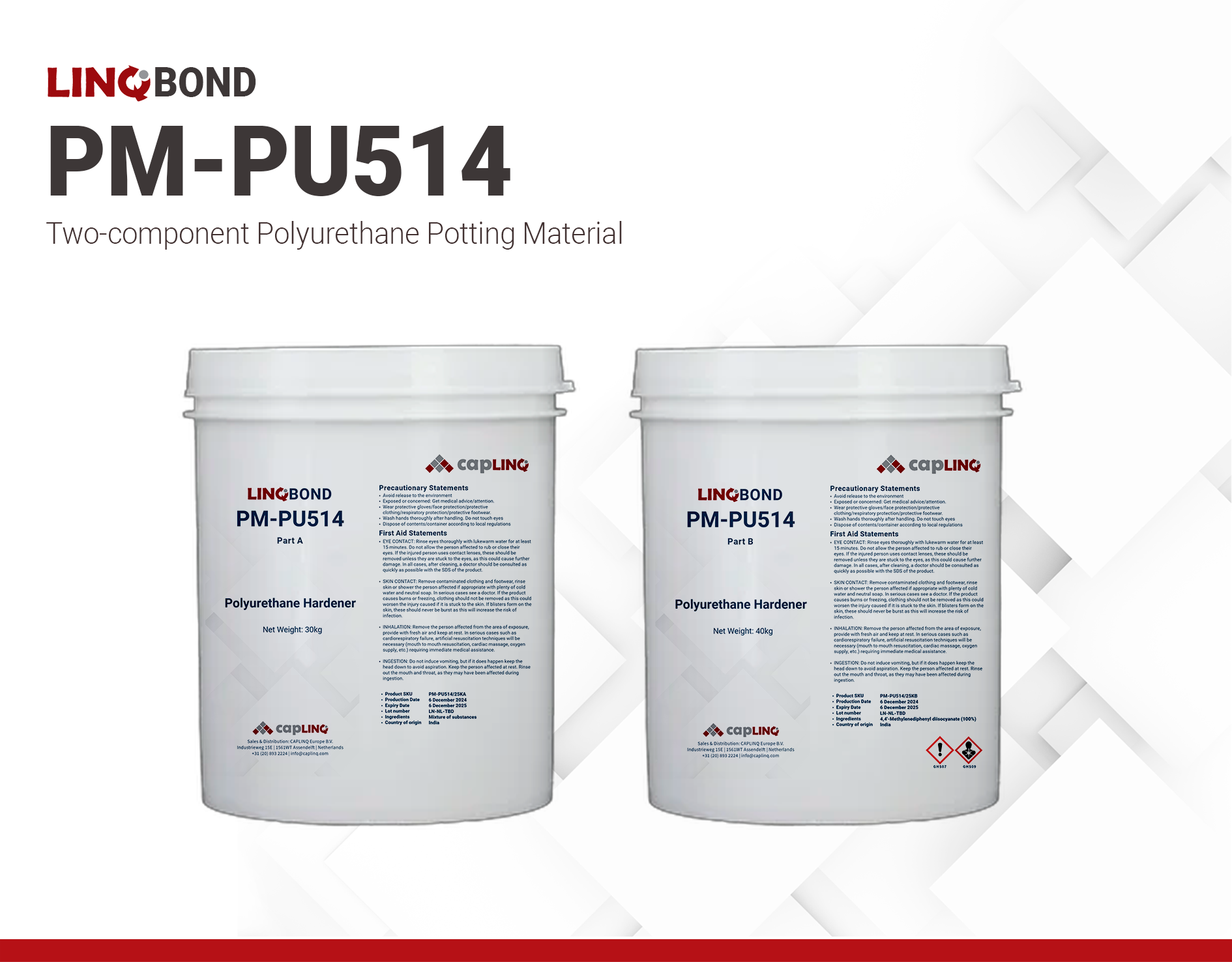

LINQBOND PM-PU514 | Two-component Polyurethane Potting Material

- Low Viscosity

- Excellent Thermal Conductivity

- Wide Temperature Range

Product Description

LINQBOND PM-PU514 is a user-friendly, two-component polyurethane system designed for electronic and filtration applications. It is formulated to have low viscosity, ensuring ease of processing. PM-PU514 is ideal for capacitor potting, PCB encapsulation, filter sealing (including HEPA), and cable jointing.

LINQBOND PM-PU514 boasts a pot life of 25-30 minutes achieving full curing within 10-12 hours at 35°C. Its thermal conductivity >0.8 W/m·K, and wide temperature working range of -60 to +135°C make it a robust solution for various industrial applications. Additionally, with a UL 94 V-0 flammability rating guarantees strong performance and outstanding reliability.. Both Parts A & B are available in 250kg drums or 25kg plastic buckets. Contact us for more information.

Key Benefits

- Low Viscosity: PM-PU514 offers low viscosity, ensuring easy application and thorough penetration into intricate components, enhancing the reliability of potting and sealing processes.

- Excellent Thermal Conductivity: With a thermal conductivity greater than 0.8 W/m·K, PM-PU514 effectively dissipates heat, protecting sensitive electronic components from thermal damage.

- Wide Temperature Range: The product's ability to perform in extreme temperatures, ranging from -60 to +135°C, makes it suitable for a variety of demanding environments, ensuring long-term stability and performance

Key Applications

- Capacitor potting

- PCB potting

- Filter sealing/HEPA filter

- Cable jointing

Technical Specifications

| General Properties | |

| Appearance Appearance Appearance at room temperature. | Off-white |

| Pot Life Pot Life Pot life is the amount of time it takes for the viscosity of a material to double (or quadruple for lower viscosity materials) in room temperature after a material is mixed. It is closely related to work life but it is not application dependent, less precise and more of a general indication of how fast a system is going to cure. | 25 - 30 minutes |

| Thermal Properties | |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 0.8 W/m.K |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 2,400 3,500 mPa.s |

Additional Information

PM-PU514 Part A & B Technical Specifications

| Property | Part A | Part B | Unit |

| Appearance | Ivory Resin | Brownish-yellow Liquid | — |

| Viscosity | 3,000 - 5,000 | 150 - 250 | cP |

| Density | 1.4 - 1.5 | 1.2 - 1.24 | g/cm3 |

PM-PU514 Mixing Ratio

| Part A (by weight) | Part B (by weight) |

| 100 | 25 |

Directions for Use

- Thoroughly stir both parts prior to mixing together.

- Mixing by Hand: Combine the required parts byweight, mix until completely mixed. Exercise caution while mixing to

minimize air entrapment. Avoid foreign containments. - Mixing and dispensing by automated equipment: Use properly rationed equipment. Use mixing system that can

properly mix part A & B.

- Mixing by Hand: Combine the required parts byweight, mix until completely mixed. Exercise caution while mixing to