LINQCELL CAT-NiMoAl

- Low overpotential for hydrogen evolution reaction

- Platinum-group metal (PGM)-free catalyst

- Optimized as cathode for alkaline water electrolyzers

Product Description

LINQCELL CAT-NiMoAl is a nickel-based electrode with nickel alloy catalyst layer deposited through plasma spray coating. It registers low overpotential for the hydrogen evolution reaction (HER), the cathodic reaction in electrochemical water splitting. While platinum is traditionally used to catalyze HER, its scarcity and high cost make transition metals like nickel strong alternatives. Nickel, in particular, demonstrates exceptional catalytic activity in alkaline solutions. CAT-NiMoAl is an improved version based on a ternary nickel–molybdenum–aluminum alloy, offering performance comparable to that of the benchmark platinum electrode, making LINQCELL CAT-NiMoAl a reliable, cost-effective, and high-performance cathode for alkaline water electrolyzers.

Key Features:

- Strong Catalytic Activity: The cathode demonstrates strong catalytic activity for the hydrogen evolution reaction (HER), crucial for efficient water splitting. This version is comparable to platinum.

- Excellent Stability: The cathodes have maintained their coating adhesion, voltage, and overall performance after 1000 hours of testing under a constant current of 10000 A/m2.

- Cost-Effective Alternative to Platinum: By using nickel-based alloys and a nickel alloy catalyst layer, the LINQCELL CAT-NiMoAl provides a more affordable solution compared to traditional platinum-based catalysts.

Highly Recommended for:

- Alkaline water electrolyzers, specifically as cathode for hydrogen production.

LINQCELL CAT-NiMoAl comes in different sizes to meet various device design requirements. Contact us for custom sizes or other specific requirements.

Technical Specifications

Additional Information

LINQCELL CAT-NiMoAl Properties

| Property | Value | Test Method / Conditions |

|---|---|---|

| Hydrogen Evolution Reaction Performance | |Current| at −1.5 V > 1.2 A | Linear sweep voltammetry (−1.5 to −0.3 V vs. Hg/HgO) |

| Mechanical Stability | Weight loss < 1% | Ultrasonication (120 W, 60 min) |

| Electrochemical Stability | Performance decay < 2% |Current| at −1.5 V > 1.2 A | Cyclic voltammetry (−1.5 to −0.3 V vs. Hg/HgO, 200 cycles) at 30% KOH, 30 °C ± 1 |

Woven Mesh Substrate Options for LINQCELL CAT-NiMoAl

Mesh 4019

Mesh 4619

Mesh 4625

What Does Woven Mesh Nomenclature, like “4619”, Mean?

Woven mesh nomenclature uses two parameters: mesh count and wire diameter. Mesh count is openings per inch (e.g., “46”), and wire diameter is the wire thickness (e.g., “19” = 0.019 mm). These set aperture size, open area, and strength. A 4619 mesh therefore has 46 openings per inch made from 0.019 mm wires—suited to filtration, screening, and electrochemical applications.

CAPLINQ’s nickel wire meshes, NWM250 and NWM300, feature 0.25 mm (250 µm) and 0.30 mm (300 µm) wire diameters, offering excellent conductivity, corrosion resistance, and durability for electrochemical/high-temperature environments.

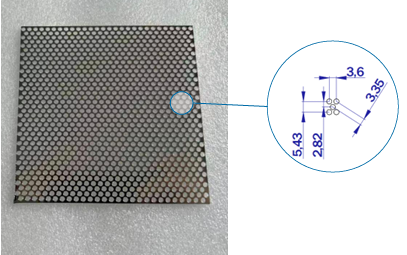

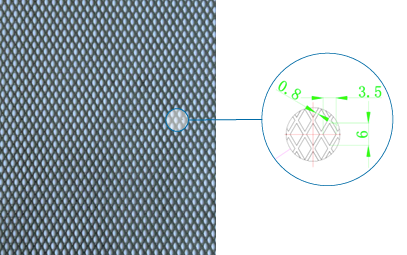

High-Rigidity Nickel Substrates for NiMoAl Cathode Catalysts

High-rigidity nickel substrates support stable NiMoAl cathodes. CAPLINQ supplies perforated nickel sheets (round openings) and expanded nickel sheets (diamond openings) engineered for high mechanical strength and dimensional stability, ensuring uniform current distribution, low contact resistance, and efficient gas removal.

Perforated Sheet with Round Openings

Expanded Sheet with Diamond Openings

Hydrogen Evolution Reaction Activity of LINQCELL CAT-NiMoAl on LINQCELL NWM250

| Component | Description |

|---|---|

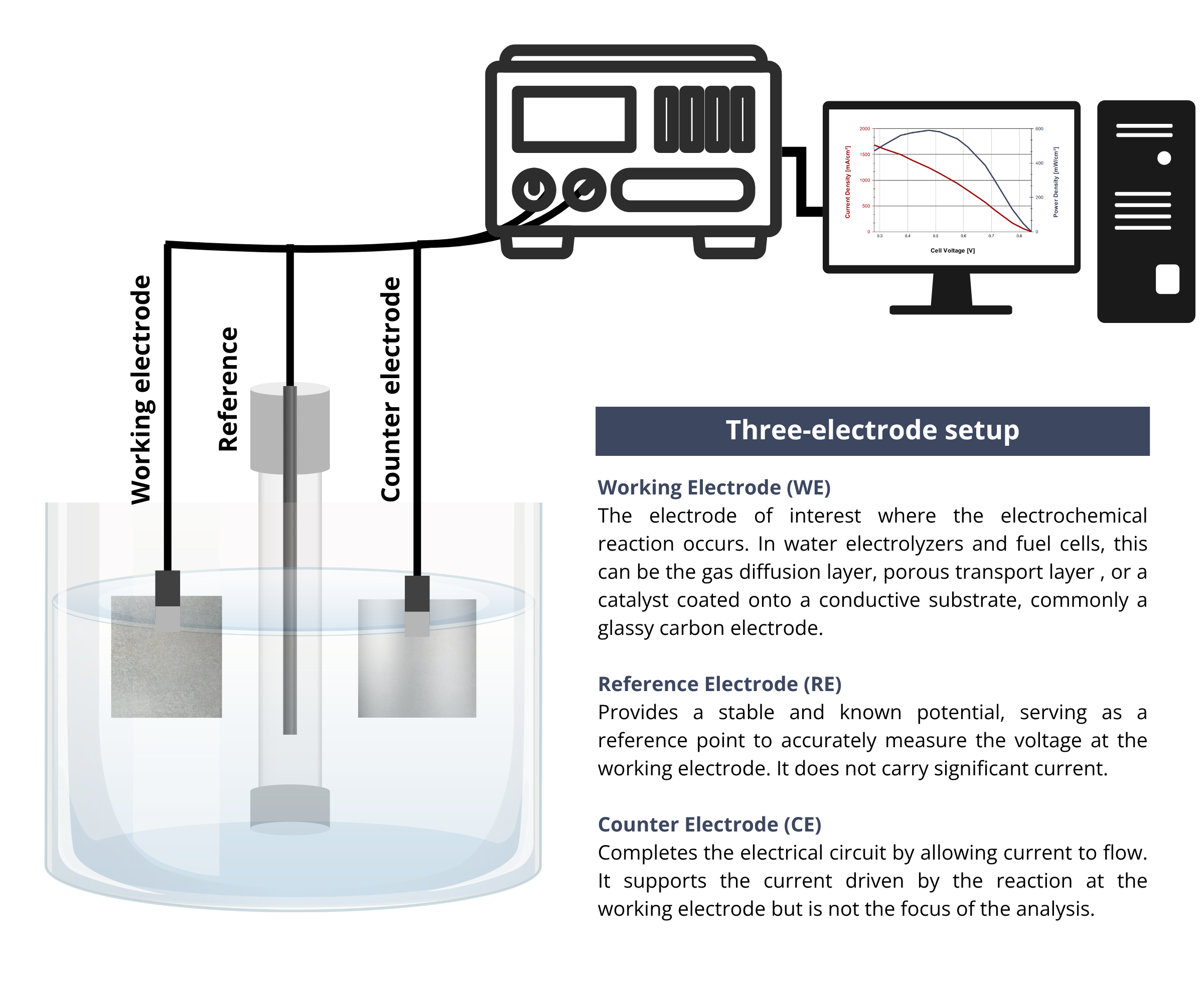

| Working Electrode (WE) | Sample (1 cm² active area, 1 cm × 1.5 cm) |

| Counter Electrode (CE) | NWM250 Ni mesh (mesh count = 46, ≥ 2 cm²); WE–CE = 2 cm |

| Reference Electrode (RE) | Hg/HgO |

Electrolyte: 30 wt% KOH; temperature: 80 ± 1 °C.

Sample Specifications

| Component | Parameter | Specification |

|---|---|---|

| LINQCELL NWM250 Nickel Wire Mesh Substrate | Substrate Material / Grade | N6 (Ni + Co ≥ 99.5%, Fe < 0.10%) |

| Wire Diameter | 0.25 ± 0.002 mm | |

| Warp/Weft Mesh Count | 46 ± 1 threads / 25 mm | |

| LINQCELL CAT-NiMoAl Cathode Coating | Catalyst Loading | 240–300 g/m² |

| Coating Thickness | ≤ 0.1 mm |

Test Protocol

The HER overpotential tests were carried out using a standard three-electrode setup with 30 wt% KOH as the electrolyte, maintained at 80 ± 1 °C.

Working Electrode Activation and Stabilization. The working electrode, with a 1 cm² active area, was first stabilized by running 20 CV cycles between –1.5 V and –0.9 V at a scan rate of 100 mV/s.

Linear Sweep Voltammetry. Once stable, linear sweep voltammetry (LSV) was performed over the same potential range at 5 mV/s. Measurements were repeated until two consecutive scans showed less than 2 mV variation at a current density of –5000 A/m². The reported overpotential values represent the average of these consistent readings at –5000 A/m² vs. RHE, with a reproducibility margin of ±2 mV.

HER Overpotential at 5000 A/m² ≤ 250 mV (vs. RHE)

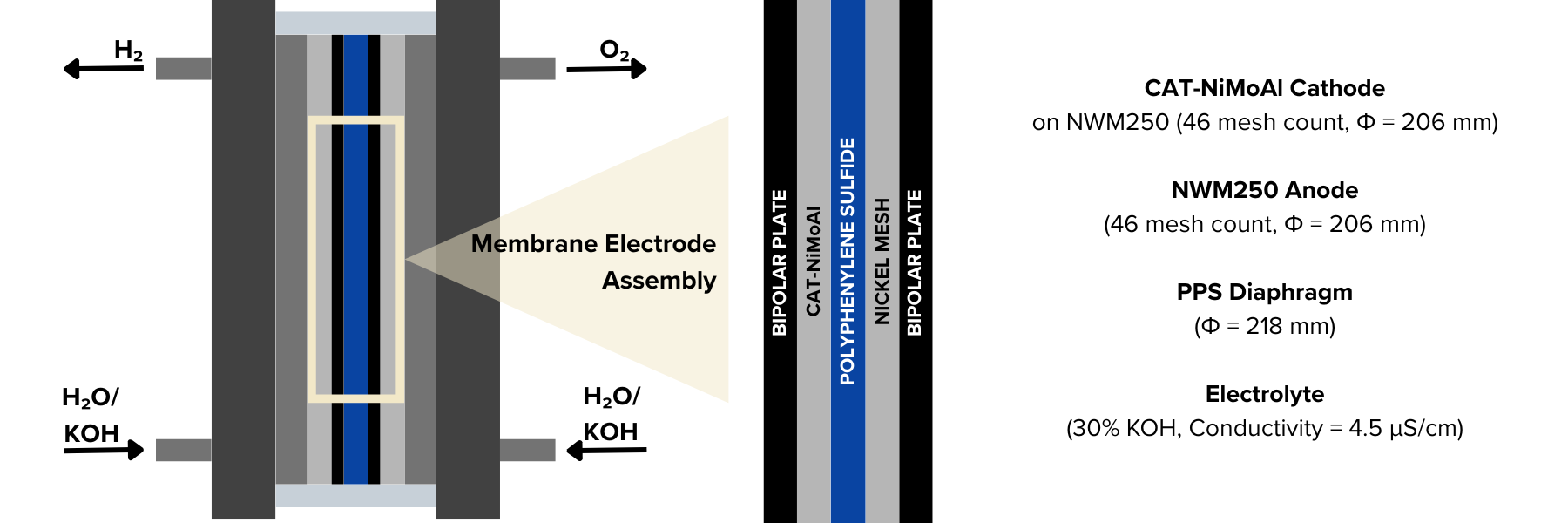

Single-Cell Test Conditions and Procedure

Materials

- Cathode: LINQCELL® CAT-NiMoAl (46 mesh, 0.25 mm wire, Ø206 mm)

- Anode: NWM250 (46 mesh, 0.25 mm wire, Ø206 mm)

- Diaphragm: Polyphenylene sulfide (PPS) (Ø218 mm)

- Electrolyte: 30% KOH (RO water, 4.48 µS/cm conductivity)

Conditions

- Stabilization: 8-hour continuous operation

- Cycling: 2-hour start-stop intervals

- Temperature: 85 °C

- Test range: 2500–4000 A/m²

Procedure

Electrode Activation

- 16-hour immersion in 20% KOH at RT (until bubble-free)

- 30-minute DI water rinse

Assembly

- Component layering with precision alignment

- Thermal steam tightening

- Leak testing verification

- System commissioning

Single-Cell Test Results with LINQCELL CAT-NiMoAl Cathode

| Current Density (A/m²) | Voltage (V)* |

|---|---|

| 2500 | 1.540 |

| 3000 | 1.562 |

| 3500 | 1.585 |

| 4000 | 1.611 |

*Average voltage from the 5th–7th measurements

Lower voltages indicate superior catalytic performance.

Characterization and Performance of LINQCELL CAT-NiMoAl Cathode for Alkaline Electrolysis

The following presentation summarizes the HER activity and single-cell performance of LINQCELL CAT-NiMoAl cathodes under alkaline electrolysis conditions. It presents the test protocols and key results.