HGP12PT | High Thermal Conductivity Putty Pad

Technical Specifications

| General Properties | |

| Color Color The color | Red |

| Film Thickness Film Thickness Film thickness is the thickness of a backing film without taking into account any coatings or adhesive layers. It is measured in micron and the conversion factor to mil is 0.039. | 0.5 - 2 mm |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 3.3 |

| Thermal Properties | |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 12.0 W/m.K |

| Thermal Impedance | 0.13 °C·cm²/W |

| UL 94 Rating UL 94 Rating Flammability rating classification. It determines how fast a material burns or extinguishes once it is ignited. HB: slow burning on a horizontal specimen; burning rate less than 76 mm/min for thickness less than 3 mm or burning stops before 100 mm V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed. V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole. 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole | V-0 |

| Electrical Properties | |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 1.0x1013 Ohms⋅cm |

Additional Information

Frequently Asked Questions About HGP12PT (12 W/m·K Ultra-Soft Thermal Putty Pad)

What are typical applications for HGP12PT?

HGP12PT is commonly used in thermal management of sensitive electronics that require extreme softness and stress-free assembly.

- Telecommunications equipment

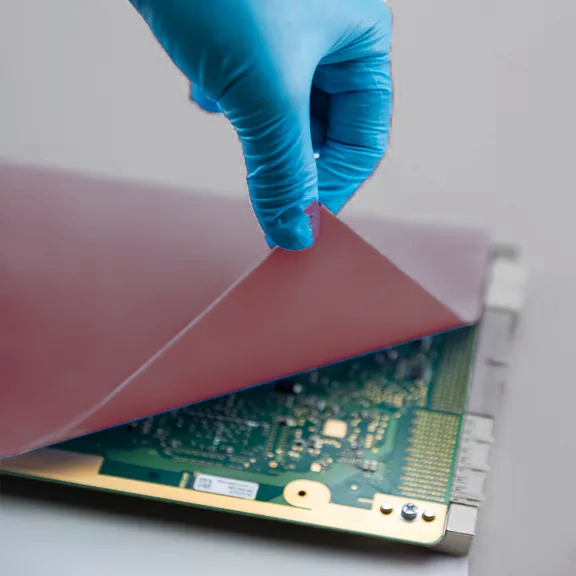

- GPU and data center systems

- High-power lighting (LED, LCD, optical)

- SSD thermal pads for controllers and NAND

- Wireless and RF modules

Learn More About HGP12PT (12 W/m·K Ultra-Soft Putty Pad)

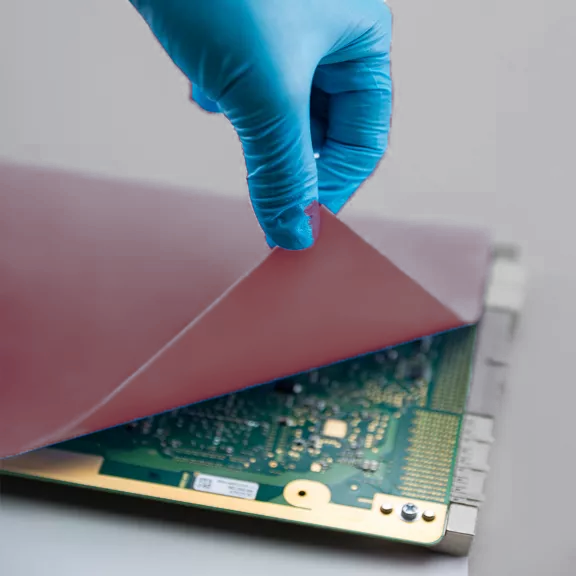

HGP12PT is an ultra-soft thermal putty pad designed to fill complex gaps with minimal force. Its tacky surface promotes good wetting, while the fiberglass reinforcement provides mechanical stability during handling and installation.

Key Features at a Glance

- ✔ 12.0 W/m·K thermal conductivity

- ✔ Ultra-soft, highly conformable structure

- ✔ Tacky surface for excellent wetting

- ✔ Fiberglass reinforcement

- ✔ Low volatile and low oil bleed

- ✔ UL 94 V-0 flame retardancy

Versatile Application Methods

Application Methods

HGP12PT is placed manually onto components. Its tacky surface ensures good adhesion during assembly, and the fiberglass layer maintains pad integrity during installation.

Reliable Across Environments

Low oil bleed, low volatility, and consistent putty-like mechanical behavior ensure reliable long-term operation from -40°C to +125°C.

Compliance You Can Trust ✅

HGP12PT meets the key requirements for high-reliability thermal interface materials.

- UL 94 V-0 flame retardant

- Low volatile content (ASTM E595)

- Low siloxane (D3–D10 <100 ppm)

- ASTM D5470 thermal validation

- ASTM D257 electrical insulation

- Operating temperature -40°C to +125°C

High-Heat, High-Conformability Applications for HGP12PT

Server motherboards frequently have inconsistent component heights that create uneven gap distances for VRMs, power inductors, and memory modules. Standard pads may not compress enough in low-pressure zones, leaving air pockets.

Power semiconductor baseplates, especially copper or DBC surfaces, may warp during manufacturing or thermal cycling, creating uneven contact areas.

Modern PCUs often have uneven housings and components with large mechanical tolerances. Traditional gap pads cannot fully conform to deep surface irregularities, resulting in poor contact and high thermal resistance.

5G and telecom hardware include sensitive and densely packed RF systems where slight misalignments create unpredictable air gaps.

Solstice HGP12PT Solution

The putty pad accommodates complex geometries and pressure variations, ensuring consistent heat transfer from RF chipsets and PA modules. Its low-modulus and compressible nature protects fragile components while preventing hotspot formation during continuous transmission. The material remains stable under high ambient temperatures common in telecom shelters and outdoor cabinets.