ABchimie 6028UV UV Cure Thixotropic Resin

- One-component

- Fast UV Curing

- Excellent adhesion to plastics

Product Description

ABChimie® 6028UV is a transparent thixotropic resin coating designed to provide mechanical and environmental protection to electronic components and assemblies. Its thixotropic quality allows for controlled application with high thicknesses (up to 4mm) without sagging. This makes it ideal for encapsulation or localized protection.

ABChimie® 6028UV is acrylic-based and has excellent adhesion to many substrates, including flexible ones like plastics. It cures rapidly under UV light, has zero VOCs, and can be applied to high-speed manufacturing processes to increase productivity. ABChimmie 6028UV is in full compliance with REACH and RoHS regulations.

Product Key Features

- Transparent, thixotropic UV-curing resin

- Allows for thick, controlled application without sagging

- Fast UV cure (mercury lamp) for high-speed processing

- Solvent-free formulation (no VOCs)

Applications

- Encapsulation of electronic components requiring high volumes, localized protection, and a thick coating

- Sensors on PCBs, wire-bonded chips, and reinforcement of solder joints.

- Can be used to seal plastic casings on PCBs

- Printed circuit assemblies.

Technical Specifications

| General Properties | |

| Appearance Appearance Appearance at room temperature. | Thixotropic translucent liquid |

| Density (g) | 1.06 g/cm3 |

| Mechanical Properties | |

| Durometer (Shore D) | 45 |

| Thermal Properties | |

| Coefficient of Thermal Expansion (CTE), α1 Coefficient of Thermal Expansion (CTE), α1 CTE α1 (alpha 1) is the slope of the Coefficient of thermal expansion in a temperature range below the Glass transition temperature (Tg). It explains how much a material will expand until it reaches Tg. | 63 ppm/°C |

| Coefficient of Thermal Expansion (CTE), α2 Coefficient of Thermal Expansion (CTE), α2 CTE α2 (alpha 2) is the slope of the Coefficient of thermal expansion in a temperature range above the Glass transition temperature (Tg). It explains the extent to which a material will expand after it passes Tg. | 118 ppm/°C |

| Flash Point Flash Point The flashpoint of a solvent is the lowest possible temperature at which it can vaporize to form an ignitable vapor. Flashpoint is often confused with “autoignition temperature”, which is the temperature at which a solvent ignites without an ignition source. | 100 °C |

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | -35.5 °C |

| Physical Properties | |

| Young's modulus | 84 MPa |

Additional Information

Frequently Asked Questions About ABChimie® 6028 UV

What are typical applications for ABChimie® 6028 UV?

ABChimie® 6028 UV is a UV-curable resin designed to protect printed circuit board assemblies (PCBs) and components in demanding manufacturing environments, including:

- Automotive electronics (e.g., control units, sensors)

- Industrial automation (e.g., motor drives, PLCs)

- Consumer electronics (e.g., smart devices, wearables)

- Other high-reliability electronic assemblies

Learn More About ABChimie® 6028 UV

ABChimie® 6028 UV is a proven solution for engineers seeking fast, reliable protection of electronic assemblies in demanding manufacturing environments. This UV-curable resin delivers rapid curing, excellent electrical insulation, and strong environmental resistance—ideal for applications in automotive electronics, industrial automation, consumer electronics, and other high-reliability assemblies.

Main Advantages of ABChimie 6028 UV

ABChimie® 6028 UV cures rapidly under UV light, enabling integration into both batch and inline production. The resin forms a durable, high-performance layer that protects assemblies while supporting high-throughput manufacturing.

ABChimie® 6028 UV cures to a Shore D hardness of 45, providing excellent mechanical protection. This hardness helps resist scratches, abrasion, and minor impacts, ensuring long-term stability of encapsulated components.

ABChimie® 6028 UV is thixotropic: it maintains a stable, non-running consistency at rest but flows easily under shear during application. This ensures precise placement, minimal sagging, and uniform coverage before rapid UV curing.

ABChimie® 6028 UV bonds strongly to flexible substrates, including plastics and polymer-based PCBs. Its adhesion ensures reliable protection even on surfaces that bend or flex, ideal for wearables, flexible electronics, and lightweight assemblies.

How to Choose a Resin

Selecting the most suitable resin requires consideration of key factors:

- ✔ Norms & Compliance

- ✔ Environment / Exposure Conditions

- ✔ Repairability

- ✔ Electrical Performance

- ✔ Application Method

- ✔ Operating Temperature

Compliance You Can Trust ✅

ABChimie® 6028 UV meets stringent industry standards, ensuring reliability and regulatory adherence for OEMs and contract manufacturers:

- REACH Compliant

- RoHS 2011/65/EU Compliant

Curing Tip: ABChimie 6028 UV cures with UV rays. It is crucial to use the appropriate equipment, as well as the recommended settings, to achieve the best properties of the resin.

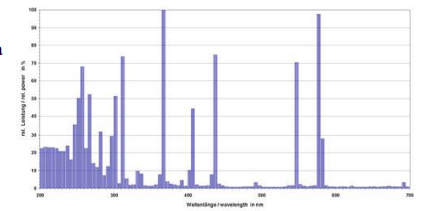

Ref. Leistung / ref power ln % over wavelength in nm

Ref. Leistung / ref power ln % over wavelength in nm

Key Curing Properties

Mercury

200-400 nm

1000 mJ/cm2

1 mm

Typical property values shown for reference only and should not be used as specifications.

Alternative to Mercury Lamp Curing of ABChimie 6028 UV

ABChimie 6028 UV is also available in the LED - version, which cures by LED Lamp.

ABChimie 6028 UV LED [Go to 6028 UV LED Product Page↗]

- Thixotropic resin

- Fluorescent under UV light

- Excellent adhesion to flexible substrates

- Immediate curing with UV LED exposure

Best suited for: High-speed process looking to use LED light for curing