Automotive Camera Module

Automotive camera modules, together with LiDAR and other sensor technologies, bring advanced safety features in concert to identify objects, pedestrians and potential hazards for the driver. They are widely used in automotive applications like advanced driver assistance systems (ADAS), surround view, driver monitoring, etc.

There are various electronic materials being applied at every level of camera construction – from the die within the image processor to component connection, thermal management, PCB protection and structural bonding of the final lens assembly. The ability to facilitate reliable performance and a clear view in temperature extremes, during rough rides and after exposure to harsh conditions, greener and more environmentally friendly formulations are tailored to the unique requirements of automotive camera systems.

Camera Module Assembly Adhesive

Module assembly requires good adhesion, flexibility, various substrate compatibility and enough electrical conductivity for grounding. These are typically easy to find properties but can be quite costly. Silver is king but there are Silver plated Cu and Nickel options that can work effectively. Module assembly adhesives are applied at interfaces including: lens barrel to lens barrel housing, lens barrel housing to PCB, lens barrel housing to camera module housing, etc.

- Good side sealing with stable volume control

- Fast cure (<60mins) and low temperature cure possible (<100°C)

- High adhesion to variety of substrate (metal, PCB, LCP, etc.)

- Operating temperature range -40~130 °C

- Low halogen content and RoHS compliant

- Good and stable electrical connection if needed (same like solder)

Product Recommendations

LOCTITE® ABLESTIK CE 3103WLV and LOCTITE ABLESTIK CE 3104WXL are rigid, Ag filled epoxies with an operating temperature of -40°C/+150°C. They are used for the bonding of non noble passive components onto noble terminated LTCC boards as well as bonding passives and discretes.

- Lead-free alternative to solder

- Anti-corrosion technology (US patents 6344157, 6583201)

- Pass NASA outgassing

- Curable using standard soldering profile

- Excellent reliability at temperature and humidity (Data Package CE3103WLV)

LOCTITE® ABLESTIK ICP 2120 (Ag filled MS polymer) and LOCTITE® ABLESTIK ABP 2034 (Ag filled BMI hybrid) are flexible conductive bonds on non-noble finishes (like Ni, SUS) with relative low temperature cure, developed for high-volume consumer devices. Both show excellent adhesion in interfaces such as SUS and Nickel in heat sensitive applications such as bracket grounding and VCM assembly for Camera modules. They can be used for batteries that require curing temperatures below 80° or even 60°C. Both products are running in volume production in Asia, regulatory review and release in Europe and Americas are pending.

- Curing 30 min @ 50°C and or 1-3 days @ 25°C (by moisture)

- Low tensile modulus (~900 MPa @ 25°C)

- Low Direct Contact Resistance (DCR <5Ω) on Ni & Stainless steel (SUS)

- Relatively high thermal bulk conductivity (7 W/mK)

- Curing 120 min @ 80°C

- Ultra low tensile modulus (~80 MPa @ 25°C, ~40 MPa >50°C)

- Low Direct Contact Resistance (DCR ~5Ω measured on Nickel)

- Combining lowest VR (0.0003 Ω-cm) with lowest modulus

Assembly Adhesives For Non-Noble Substrate

| PROPERTIES | ABP2034 | ICP2175 | 8175 | CE3103WLV | CE3104WXL | CE3920 |

| Chemistry | Acrylic/BMI | MS Polymer | Epoxy | Epoxy | Epoxy | Epoxy |

| Benefits | Low temp cure Ultra-low modulus | Excellent DCR Low temp cure | Stencil printable Stress absorbing | Low viscosity Anti-corrosion | Stencil printable Anti-corrosion | Low viscosity Low CTE |

| Viscosity | 32,000 mPa·s | 28,000 mPa·s | 55,000 mPa·s | 20,000 mPa·s | 65,000 mPa·s | 65,000 mPa·s |

| Thixotr. Index | 6.6 | 2.5 | 2.0 | 5.5 | 6.0 | 5.7 |

| Pot Life @25°C | - | - | 14 days | 72 hours | 72 hours | 72 hours |

| Storage Temp | -20 °C | -40 °C | -40 °C | -40 ~ -35 °C | -40 ~ -35 °C | -40 °C |

| Tg by TMA | 18 °C | - | 90 °C | 114 °C | 119 °C | 100 °C |

| CTE1, CTE2 | 46, 120 ppm/°C | - | 55, 200 ppm/°C | 45, 225 ppm/°C | 29, 130 ppm/°C | 40, 200 ppm/°C |

| Volume Resistivity | 1.2 * 10-3 Ωcm | 1.0 * 10-4 Ωcm | 0.5 * 10-3 Ωcm | 0.8 * 10-3 Ωcm | 0.7 * 10-3 Ωcm | 0.3 * 10-3 Ωcm |

| Cure Schedule | 120 min @80°C | 30 min @50°C | 30 min @150°C | 10 min @120°C or 3 min @150°C | Reflow oven: 5 min @125°C; Convection oven: 8 min @125°C | 5 min @150°C |

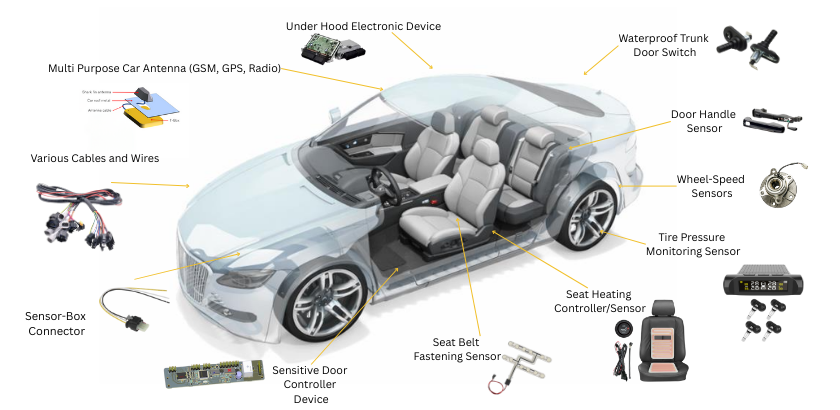

Other Automotive Sensor's Adhesive

As safety regulations become more stringent and consumer demand drives greater product miniaturization and advanced electronic connectivity across industries—from automotive to smartphones—the need to effectively protect electronic components from moisture, dust, and contaminants is more critical than ever. Low-pressure molding (LPM) materials provide engineers and designers with a reliable solution by:

- Reducing manufacturing complexity and overall production cost

- Delivering excellent electrical insulation and environmental protection

- Supporting sustainability goals through reduced material waste and improved process efficiency

Low-pressure molding (LPM) materials, typically polyamide-based hot-melt resins, are widely used in automotive electronics to protect and encapsulate sensitive sensor components. In modern vehicles, sensors such as door handle sensors, seat belt fastening sensors, wheel-speed sensors, tire pressure monitoring systems (TPMS), and under-hood electronic devices require reliable protection against moisture, vibration, dust, and temperature fluctuations.

LPM materials are processed at low injection pressures, minimizing mechanical stress on delicate PCBs, wire bonds, and connectors commonly found in automotive sensors. This makes LPM especially suitable for overmolding fine wires, sensor housings, and compact electronic modules without damaging internal components.

In applications such as waterproof trunk door switches, cable assemblies, and sensor box connectors, LPM provides excellent sealing performance and environmental protection. The material forms a robust yet flexible encapsulation, improving resistance to water ingress, chemicals, and automotive fluids while maintaining dimensional stability.

Additionally, LPM materials offer good adhesion to plastics, metals, and cable jackets, enabling reliable strain relief for wires used in seat heating controllers, antenna modules (GSM, GPS, radio), and interior sensor systems. With fast cycle times and low material waste, LPM is a cost-effective solution that meets automotive reliability and durability requirements.

Low-Pressure Molding Polyamide Hot Melt Products

Need a reliable low pressure molding adhesive for your electronic assemblies? Review our product range below to identify the best fit for your protection and performance requirements.

Product | Operating Range (°C) | Shore Hardness (ISO 868) (Instant/15s) | Viscosity at 25°C (Pa.s) | Softening Point (°C) (ASTM D3461) | Typical Characteristic |

-40°C to 150°C | 38/27 D | 3.0-4.0 | 183°C ±5°C | General-purpose high-performance moldable polyamide with good adhesion and environmental and thermal shock resistance. Used for applications such as automotive exteriors. | |

-40°C to 150°C | 40/32 D | 4.0-6.0 | 180°C ±5°C | Moldable polyamide with very good thermal stability as well as UV and moisture resistance. Available in black only. | |

-20°C to 150°C | 45/40 D | 3.0-4.0 | 200°C ±5°C | Moldable polyamide with excellent thermal stability and increased hardness for electronics over-molding. | |

-55°C to 120°C | 30/16 D | 2.5-3.5 | 157°C ±5°C | Moldable polyamide with very good low-temperature resistance and good adhesion for automotive applications. |