Aerospace Memory & Data Storage

Aerospace data storage is a mission-critical component that enables the capture, processing, and preservation of data across flight operations, space missions, and ground support activities. Modern aerospace storage systems must handle diverse data types, including avionics control instructions, navigation databases, satellite imagery, payload data, and health monitoring logs.

Types of Aerospace Memory: Volatile and Nonvolatile Data Storage

Data storage memory in aerospace systems is generally divided into two categories: volatile and nonvolatile.

Volatile Memory

Volatile memory depends on continuous power to retain information; when power is interrupted, data is erased. In aerospace systems it’s valued for speed and efficiency, ideal for real-time operations and temporary storage, but unsuitable for long-term retention.

Most Common Type: SRAM

SRAM stores data in flip-flop circuits, making it faster, more stable, and lower in latency than DRAM. Radiation-tolerant variants make it the preferred volatile memory for aerospace despite higher power use and cost.

PROs: Fast, stable, low latency; radiation-tolerant options.

CONs: Higher power use and cost; no long-term data retention.

USE CASES: Flight computers, avionics, cache memory, high-speed onboard processing.

Nonvolatile Memory

Nonvolatile memory preserves data without power, indispensable where mission data and logs must survive resets and power cycles.

Most Common Types: Flash & MRAM

Flash provides high-density storage for telemetry and mission data, while MRAM adds radiation tolerance and faster access where both persistence and speed are needed.

PROs: Retains data without power; secure for long missions; space-qualified versions exist.

CONs: Slower than volatile memory; limited write endurance; higher cost.

USE CASES: Flight software, telemetry logging, payload data, system health monitoring.

Key Environmental Factors Affecting Data Storage

Aerospace memory must perform reliably under extreme conditions. Conventional memory (hard drives, flash, DRAM) cannot be directly applied in aircraft or spacecraft due to radiation, vacuum, and thermal extremes. Specialized, radiation-hardened memory is required.

Radiation

Cosmic rays and solar radiation cause bit errors, latch-ups, and long-term degradation. Single-event upsets (SEUs), total ionizing dose (TID), and displacement damage reduce reliability and lifespan.

Temperature Effects

Memory must withstand freezing space conditions and re-entry heat. Low temperatures cause brittle failures, while heat accelerates leakage currents, expansion, and degradation.

Vacuum & Outgassing

Low-pressure environments can cause polymers and adhesives to outgas, depositing vapors on surfaces. Vacuum also complicates thermal management, raising overheating risks.

Vibration & Shock

Launch and re-entry stresses cause solder fatigue and connector loosening. Sudden shocks or vibration can corrupt signals and shorten lifespan if not reinforced.

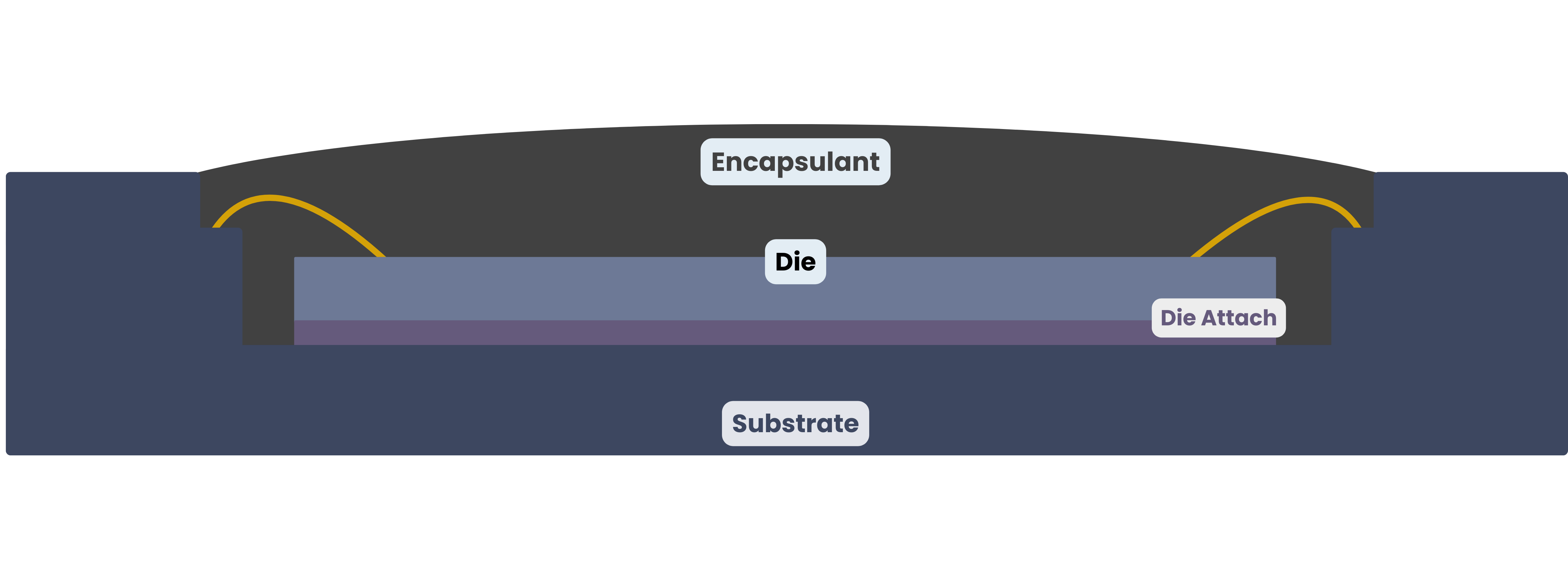

Materials in Aerospace Memory Packaging

Reliability is achieved through materials and packaging rather than the circuit itself. Hermetic ceramic packages, Au wire bonds, low-outgassing encapsulants, and radiation-tolerant CMOS enable memory to survive extreme aerospace conditions.

Die Attach in Aerospace Memory

Die attach secures the memory die, transfers heat, provides backside grounding, and must meet strict low-outgassing standards (ASTM E595 / ECSS-Q-ST-70-02). Conductive die attach is most common since aerospace memory dies are often tied to ground.

Au–Sn Eutectic

- Benchmark for aerospace memory packaging, including SRAM, MRAM, and EEPROM

- Delivers a clean, flux-free bondline, high thermal and electrical conductivity, and hermetic reliability critical for space-grade applications

- Yields void-free joints in ceramic and Kovar packages

Limitations: Expensive, high reflow temperature, CTE mismatch risks

Ag-Filled Epoxy

- Thermosetting silver-filled epoxy die attach cured at 150–180 °C

- Provides electrical grounding, stress absorption, and space-qualified low-outgassing formulations.

Limitations: Lower thermal conductivity, non-hermetic, radiation aging.

Recommended Conductive Die Attach for Aerospace Memory

For aerospace memory die attach, we want:

- Low TML (<0.2%) and low CVCM (~0%) to minimize outgassing in space environments

- Cure schedule compatible with memory dies and ceramic packages to reduce thermal stress

- Good thermal and electrical conductivity to manage heat and provide reliable backside grounding

Henkel conductive die attach meets these requirements. It is a silver-filled polymer adhesive engineered for aerospace memory devices, including SRAM, MRAM, and EEPROM. The formulation delivers high thermal and electrical conductivity for efficient heat dissipation and reliable backside grounding, mechanical compliance to absorb vibration and CTE mismatches, and low outgassing for long-term space reliability. Many Henkel grades have passed NASA TML/CVCM outgassing tests, and some also meet MIL-STD-883 Method 5011, ensuring proven, mission-ready performance in extreme aerospace environments.

Featured Products

LOCTITE ABLESTIK 84-1LMI ↗

High-performance silver-filled epoxy die attach for microelectronics

- TML: 0.12% | CVCM: 0 | Cure: 1 h at 150 °C

- Suitable for rad-tolerant memories (SRAM, MRAM, Flash) in LEO satellites, CubeSats, and constellations where mission duration is shorter and thermal loads are modest

LOCTITE ABLESTIK 84-1LMIT ↗

Aerospace and military-grade silver-filled epoxy die attach with high thermal conductivity

- TML: 0.14% | CVCM: 0.01% | Cure: 1 h at 150 °C

- Common in rad-hard memory devices for GEO comm satellites, military satellites, and deep-space probes when Au–Sn eutectic solder is not required; offers higher reliability and screening pedigree than 84-1LMI

LOCTITE ABLESTIK 2902 ↗

Low-temperature cure silver-filled epoxy die attach for heat-sensitive devices

- TML: 0.19% | CVCM: 0.02% | Cure: 2 h at 120 °C

- Best for rad-tolerant CubeSat or smallsat memory devices where low-temperature cure is critical (e.g., thin ceramic packages, delicate metallizations). Less common in long-duration rad-hard missions due to lower thermal conductivity.

Underfills for Aerospace Memory

In aerospace memory devices, the standard step after die attach is wire bonding. Gold wire wedge bonds are commonly used in rad-hard memory because of their corrosion resistance, fatigue endurance, and proven reliability in hermetic ceramic packages.

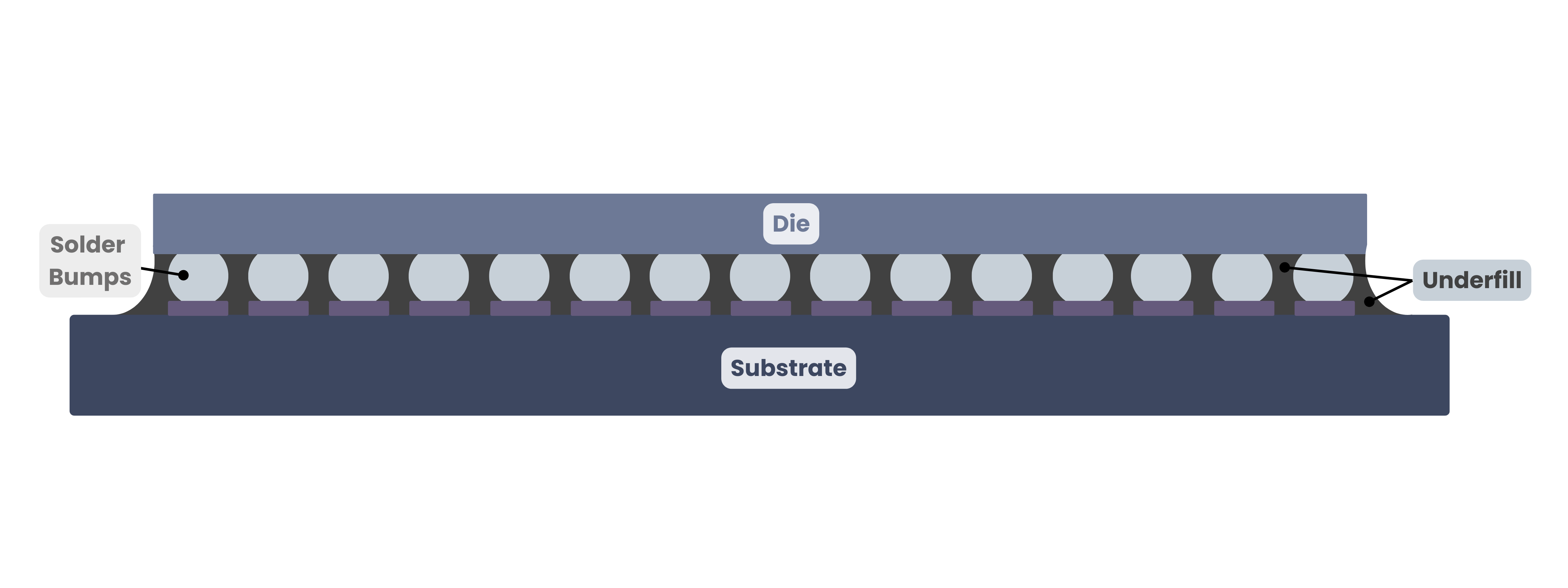

For radiation-tolerant memory packaged in plastic ball grid arrays (BGAs), chip scale packages (CSPs), or flip-chip formats, underfill materials are often applied. The underfill encapsulates solder bumps or bond regions, reducing thermo-mechanical stress, protecting against vibration and shock, and improving device reliability and life under repeated thermal cycling.

Why use an underfill in aerospace memory?

- Distributes CTE-induced stress across solder joints and interconnects

- Improves shock and vibration resistance in launch and LEO environments

- Enhances thermal cycling reliability and extends device lifetime

Illustration: Flip-chip package with capillary underfill around solder bumps.

In summary

- Rad-hard memory: Wire bonding only; hermetic ceramic package provides protection.

- Rad-tolerant memory: Wire bonding with optional underfill, especially for flip-chip, BGA, or large-die aerospace memory devices in LEO missions, to enhance reliability and thermal/mechanical stress resistance.

Recommended Underfills for Aerospace Memory

To help select the right underfill for aerospace memory devices, the table below summarizes Henkel underfill products, their outgassing performance (TML/CVCM), cure schedules, and best use cases for different memory types and mission profiles. This guide supports flip-chip, BGA, and large-die SRAM, MRAM, Flash, and DRAM applications in LEO satellites and other space environments.

| Product | TML % / CVCM % | Cure Schedule | Best Aerospace Use Case | Memory Type / Mission |

|---|---|---|---|---|

| ECCOBOND FP4545FC | 0.23 / 0.01 | 1 hr at 165 °C | General-purpose flip-chip underfill with low outgassing | Flip-chip SRAM or MRAM in LEO satellites |

| ECCOBOND UF1173 | 0.43 / 0.02 | 5 min at 150 °C | Fast-cure underfill for higher-throughput assembly, where moderate outgassing is acceptable | Plastic BGA Flash/DDR in CubeSats / smallsats |

| ECCOBOND UF3811 | 0.45 / 0.04 | 1 hr at 100 °C | Low-temperature cure for sensitive substrates or dies | Large die Flash or DRAM modules in LEO constellations |

| ECCOBOND FP4531 | 0.20 / 0.03 | 7 min at 160 °C | Aerospace-grade flip-chip underfill with very low TML; widely used | MRAM or SRAM dice in medium-lifetime satellites |

| ECCOBOND 3128 | 0.40 / 0.01 | 20 min at 80 °C | Ultra-low cure temp underfill for delicate or low-CTE substrates | DDR3/DDR4 in CubeSats or short-duration demo missions |

Encapsulation for Aerospace Memory

Encapsulation in aerospace memory devices, similar to encapsulation in terrestrial semiconductor packages, is a critical step that ensures environmental protection, hermeticity, and long-term reliability. Hermeticity provides an airtight seal that prevents moisture, gas, or contaminant ingress, maintaining stable performance of SRAM, MRAM, EEPROM, Flash, and DDR memory in extreme space and satellite environments.

Illustration: Encapsulation around die and interconnects to resist moisture, shock, and thermal cycling.

Why encapsulation matters

- Maintains hermeticity or provides environmental protection in non-hermetic packages

- Reduces thermo-mechanical stress on wires, bumps, and interconnects

- Improves reliability through launch shock, vibration, and thermal cycling

The encapsulation material is selected based on radiation protection requirements—radiation-hard or radiation-tolerant—to ensure reliable operation and mission-ready performance in aerospace applications.

| Encapsulation Material | Rad-Hard Memory (Hermetic, GEO/Deep Space) | Rad-Tolerant Memory (Plastic, LEO/CubeSat) |

|---|---|---|

| Ceramic (Alumina, HTCC, LTCC) | Recommended — Primary package body; provides hermeticity, radiation stability, and mechanical rigidity | Not recommended — Rare (too costly for rad-tolerant devices) |

| Metal / Glass Seals (Kovar lids, Au–Sn solder, glass-to-metal seals) | Recommended — Standard for lid sealing; cavity filled with dry N₂ | Not used — Plastic encapsulation instead |

| Epoxy Molding Compound (EMC) | Avoid — Would outgas in hermetic packages | Recommended — Primary encapsulant for plastic BGA/TSOP; use low-outgassing, NASA-approved EMCs |

| Liquid Epoxy Encapsulants (glob-top, staking) | Avoid — Not for bulk coverage; occasional tiny dots for wire-bond staking | Recommended — Glob-top over die/wires; selective staking; ASTM E595 compliant (e.g., Henkel ECCOBOND FP4531, 3128) |

| Silicone Encapsulants / Gels | Avoid — Not used inside hermetic cavity | Sometimes — Used for stress relief in board-level assemblies; low-outgassing grades only |

Recommended Liquid Encapsulants for Aerospace Memory

In addition to epoxy molding compounds, liquid encapsulants can also be used in aerospace memory, especially for radiation-tolerant packages. These flowable epoxy, silicone, or urethane resins are applied over the die and bond wires, then thermally cured to form a protective barrier. When formulated to meet NASA outgassing standards, they protect the package mechanically and relieve stress, ensuring reliable operation in space.

Featured Products

LOCTITE STYCAST 2850FT↗

Two-part, filled epoxy encapsulant designed for potting and protecting high-reliability electronics

- Provides excellent thermal conductivity and mechanical strength to dissipate heat and withstand vibration

- Low shrinkage and dimensional stability ensure long-term reliability under thermal cycling

- Used to pot and encapsulate hybrid memory modules (SRAM, EEPROM, MRAM) in ceramic packages, where vibration damping and thermal management are critical in aerospace missions

LOCTITE ECCOBOND E 1216M↗

General-purpose aerospace encapsulant with low outgassing

- Capillary flow with strong adhesion, providing mechanical support to solder joints and die interfaces

- Low ionic content and ability to pass ASTM E595 NASA outgassing make it suitable for space hardware

- Applied as an underfill in ceramic and organic memory packages for satellites and rad-tolerant systems

OPTOLINQ OLS-1000↗

Optically-clear halogen-free epoxy encapsulant designed for LED packaging, optoelectronics, and advanced microelectronics

- Provides high optical transparency with multiple viscosity options: LV (low viscosity for flow), HV (higher body), HF (halogen-free compliance)

- Low haze, minimal discoloration, and good outgassing performance

- Can be used as glob-top and cavity encapsulants in aerospace memory hybrids and optoelectronic assemblies, enabling visual inspection and low-outgassing protection in radiation-tolerant systems

Conformal Coatings for Aerospace Memory

Conformal coating is not applied during wafer-level or package-level fabrication steps such as die attach, wire bonding, molding/encapsulation, lid sealing, or hermetic sealing. Instead, conformal coatings come into play later, at the board-level assembly stage, once the packaged aerospace memory devices are mounted onto printed circuit boards (PCBs) or hybrid modules.

Why do aerospace memory PCBs need conformal coating?

- Protects against humidity and condensation to prevent corrosion and short circuits on memory boards.

- Prevents oxidation of solder joints, connectors, and exposed metals for long-term PCB reliability.

- Improves electrical insulation, reducing leakage currents and stabilizing memory performance.

- Reinforces solder joints and components to resist vibration and mechanical stress during launch and operation.

- Minimizes outgassing in vacuum when using aerospace-qualified conformal coating formulations.

- Adds an extra barrier beyond package-level sealing, boosting overall module durability.

Where it fits in the flow

Conformal coatings are applied after memory devices are packaged and assembled onto the PCB or hybrid module. They complement, but do not replace, package-level protections like hermetic lids or encapsulants, providing board-level environmental protection and mechanical robustness for the complete assembly.

Conformal Coating Base Chemistries

Conformal coatings for aerospace electronics include acrylic, urethane, silicone, epoxy, and parylene. Each resin chemistry balances moisture resistance, chemical durability, thermal stability, flexibility, and reworkability, making selection dependent on mission reliability and cost requirements.

Acrylic

Pros: Fast dry, easy rework, cost-effective for general aerospace use.

Cons: Limited chemical and temperature resistance.

Urethane

Pros: Strong resistance to moisture, chemicals, and abrasion.

Cons: Rigid; long cure; difficult to rework.

Silicone

Pros: Excellent flexibility and thermal stability for high-temperature use.

Cons: Hard to remove; chemical resistance varies by grade.

Epoxy

Pros: Durable, high adhesion, chemical and abrasion resistant.

Cons: Brittle; not easily reworked; check outgassing properties.

Conformal Coatings for Aerospace Memory

There is no single “best” conformal coating chemistry for aerospace memory or aerospace electronics. The right choice depends on mission profile, environment, and reliability. Acrylics suit cost-sensitive boards; silicones, high-temperature stability; urethanes, chemical resistance; epoxies, durability; parylene, maximum reliability.

HumiSeal 1C49LV ↗

Flexible silicone conformal coating engineered for extreme temperature cycling and low outgassing in aerospace electronics.

- Operating range –65 to +200 °C for avionics and satellite reliability.

- Strong dielectric insulation and moisture protection for dense memory circuits.

- Applied on DRAM modules in aerospace memory boards to withstand vibration and thermal shock.

HumiSeal 1C53 ↗

Single-component, silicone conformal coating designed for high-reliability electronics

- High solvent and chemical resistance against hydraulic fluids and cleaners.

- Qualified to MIL-I-46058C and IPC-CC-830 (common requirements for military/aerospace electronics).

- Used on EEPROM and Flash memory boards in avionics requiring solvent resistance and long-term durability.

HumiSeal 2A53 ↗

Rigid epoxy conformal coating providing strong environmental and electrical barrier protection for aerospace electronics.

- High dielectric strength and moisture resistance for stable data retention.

- Effective barrier against aggressive chemicals and contaminants.

- Selected for non-volatile memory controller modules in aerospace systems needing rigid encapsulation.

Final Aerospace Memory Recommendation

All three recommended products are qualified to MIL-I-46058C and IPC-CC-830B, ensuring compliance with aerospace and defense coating standards.

Primary coating: HumiSeal 1C49LV → best balance of NASA outgassing compliance, thermal range, and electrical stability.

Secondary options:

- 1C51 / 1C53 if extra chemical/solvent resistance is required.

- 2A53 if rigid encapsulation is needed and outgassing can be managed with pre-baking.

Frequently Asked Questions about Data Storage in Aerospace Systems

Yes, but with limitations. Commercial plastic-packaged memories are suitable only for low-radiation, short-duration missions, such as LEO satellites or small CubeSats. They are not recommended for GEO, deep-space, or high-radiation environments, because they lack radiation hardening, can degrade under vacuum or thermal cycling, and generally do not meet NASA outgassing or MIL-STD-883 standards. For long-term, mission-critical space applications, radiation-tolerant or hermetic aerospace-grade memory is strongly advised.

What is the difference between radiation-hard and radiation-tolerant memory?The key difference is radiation resilience. Radiation-hard (rad-hard) memory is built on hardened processes that withstand total ionizing doses (TID ≥100–300 krad(Si)) and resist single-event effects (SEE) such as SEUs, SELs, and SEBs, making it ideal for deep-space missions and GEO satellites.

Radiation-tolerant (rad-tolerant) memory typically tolerates TID 10–50 krad(Si) and is not fully immune to single-event effects, relying on system-level mitigation such as error-correcting codes (ECC), scrubbing, and limited shielding, making it suitable for LEO satellites and medium-radiation environments.

What standards govern aerospace memory packaging materials?Aerospace memory packaging standards ensure SRAM, MRAM, EEPROM, Flash, and DDR memory operate reliably in LEO, GEO, and deep-space missions. Key standards include:

- NASA Outgassing Requirements (ASTM E595 / TML & CVCM): Limit mass loss and volatile emissions in vacuum.

- MIL-STD-883: Defines mechanical, thermal, and hermeticity tests for space-grade microelectronics.

- ECSS-Q-ST-70-02: European standard for low-outgassing, radiation-tolerant, and reliable materials.

The main difference lies in environmental and reliability requirements. Military-grade memory is designed for harsh terrestrial conditions, such as extreme temperature, shock, and vibration, following standards like MIL-STD-883. Aerospace-grade memory meets stricter space-specific standards, including NASA outgassing, radiation tolerance, hermetic sealing, and long-term reliability in LEO, GEO, or deep-space environments.

What are the main failure mechanisms for aerospace memories?

Aerospace memories can fail due to:

- Radiation effects: SEUs, SELs, SEBs, and TID degradation.

- Thermal stress: Extreme cycles causing die cracking or bond wire fatigue.

- Mechanical stress: Vibration, shock, and CTE mismatch.

- Material degradation: Outgassing, corrosion, or epoxy/underfill embrittlement.

- Packaging defects: Voids, incomplete encapsulation, poor hermetic sealing.

How long can aerospace memory retain data?

Aerospace and space-grade memories typically offer retention of 10–20 years under nominal conditions.

- MRAM: 10–20 years, near-infinite endurance.

- Hermetic STT-MRAM: >10 years in LEO, MEO, GEO, HEO.

- High-density Flash/NVM: ~20 years at –55 °C to +125 °C.

- SRAM/MRAM hybrids: ~10 years at ~125 °C.

Actual mission lifetime depends on write frequency, thermal cycling, vibration, radiation exposure, and space stresses.

Related Blogs

How Outgassing in Materials is Tested: Key Parameters and Procedures

This blog explains how outgassing in materials is tested, covering the key parameters, such as Total Mass Loss (TML) and Condensed Volatile Materials (CVM), and standard procedures (ASTM E595) to ensure material reliability in high-vacuum, high-temperature, aerospace, and electronics applications.