ALPHA OM-535

Harmonization Code : 3810.10.00 | Soldering, brazing or welding powders and pastes consisting of metal and other materials

Main features

- Enables elimination of a second or third reflow cycle

- 8+ Hour stencil life

- Compatible with all commonly used Pb-free surface finishes

Product Description

ALPHA OM-535 features a low-temperature solder paste technology that enables a single reflow application for the assemby of double-sided boards. It has excellent no-solder drip phenomena during the reflow process. ALPHA OM-535 with SBX02 alloy has been successfuly used with peak reflow profiles between 155 - 190℃. This version also shows a higher mechanical strength and drop shock resistance than SnBi0.4Ag alloy. The flux in ALPHA OM-535 has excellent electrical resistivity than exceeds industry standards.

ALPHA OM-535 enables the elimination of an extra wave or selective wave soldering process when temperature sensitive through-hole components are used in an assembly.

Product Key Features

- Increased daily throughput, eliminating the need for managing wave solder.

- Removes the need for an extra SMT process, which significantly lower the cost of producing an electronic assembly.

- The alloys yield very low voiding BGA solder joints, even when a traditional SAC alloy sphere is used.

Applications

Technical Specifications

| General Properties | |

| Color Color The color | Light Yellow ~ Yellow Residue |

Additional Information

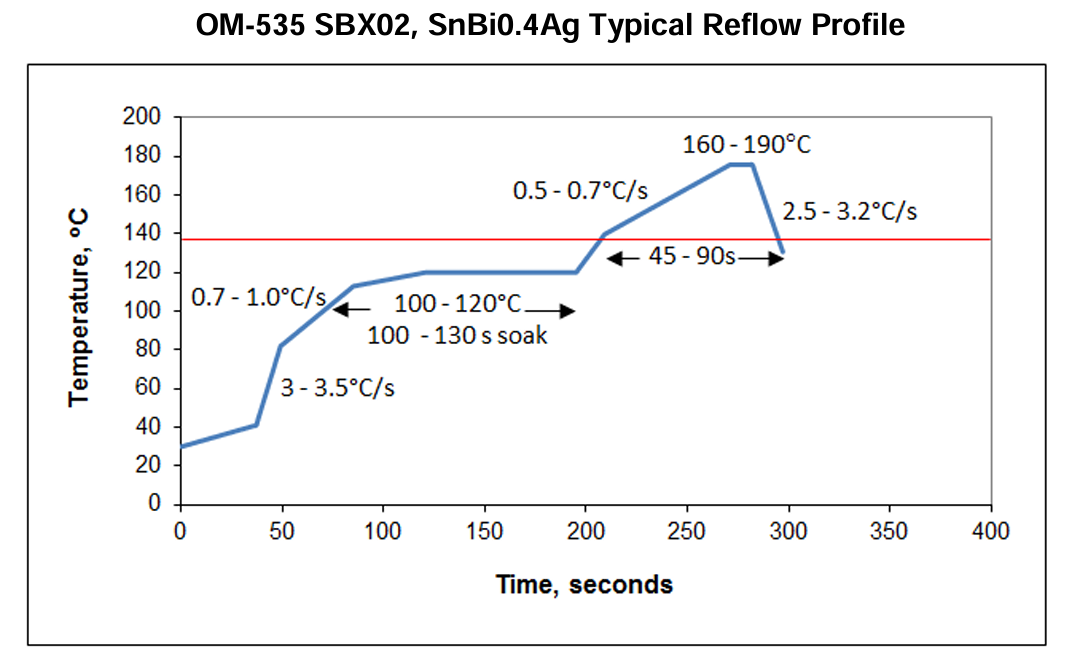

OM-535 Reflow Profile

Application

- STENCIL: Recommend ALPHA CUT, ALPHA NICKEL-CUT, ALPHA TETRABOND®, or ALPHA FORM stencils @ 0.100 mm - 0.150 mm (4-6 mil) thick for 0.4 - 0.5 mm (0.016” or 0.020”) pitch. Stencil design is subject to many process variables. Contact your local Alpha stencil site for advice.

- SQUEEGEE: Metal recommended

- PRESSURE: 0.21 - 0.36 kg/cm of blade (1.25 -2.0 Ibs/inch)

- SPEED: 25 – 100 mm per second (1 – 6 inches per second)

- PASTE ROLL: 1.5-2.0 cm diameter and make additions when roll reaches 1 cm (0.4”) diameter (min). Max roll size will depend upon blade.

- STENCIL RELEASE SPEED: 1 – 5 mm/sec

- LIFT HEIGHT: 8 – 14 mm(0.31 – 0.55”)