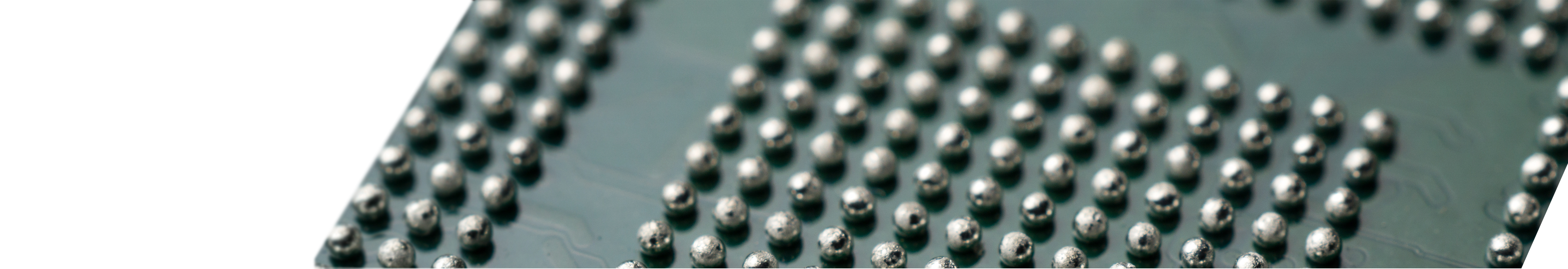

Flip Chip BGA

Flip Chip BGA (FCBGA) packages are assembled around state‑of‑the‑art, single unit laminate or ceramic substrates: (1) Flip Chip Organic BGA - Laminate or build-up organic substrate offers better electrical performance than wire-bond type BGA package especially in high frequency applications; (2) Flip Chip Ceramic BGA - Alumina ceramic substrate offers better moisture resistance, electrical insulating property and higher thermal conductivity than organic substrate. FCBGA is used primarily for high-reliability commercial applications (e.g. CPU). By combining flip chip interconnect with ultra advanced substrate technology, FCBGA packages can be electrically tuned for maximum electrical performance with a high routing density.

Key Features

- High performance and low cost package solutions

- Superior thermal peformance with copper or aluminum lid/heat spreader

- Package sizes from 10 mm to 67.5 mm

- Pb-free, and Cu pillar as bumps

- SMT components on top or bottom side

- Multi-die capability

- Computing: Memory, CPU, APU, GPU, HDD storage

- Network: small cell base station, network storage driven by cloud computing and high speed processors

- Comsumer: DTVs, STBs, game consoles and IOT

- Moisture Sensitivity Level: JEDEC Level 4 or 3@260°C

- Temperature Cycling Test: -55°C/125°C, 1000 cycles

- High Temperature Storage: 150°C, 1000hrs

- Highly Accelerated Stress Test: 130°C, 85%RH, 2 atm, 96 hrs

The above are typical condition numbers.

| Product Recommendation For FCBGA Assembly | ||

| Semicondutor Capillary Underfill (CUF) | Board Level Underfill | Lid Attach Adhesive For BGA |

UF8828 FP4511 FP4549 (HT) | Conductive Lid Attach Non conductive Lid Attach

| |

|

|

|

BGA Lid attach.

- MC723

- 3003

- 3005

- 3188

BGA Encapsulation

Integrated circuits are extremely vulnerable packages that need protection from the outside world. They need to be thermally, mechanically and electrically insulated in order to endure operational conditions.

Ball Grid array underfills

Additionally, underfills help with thermal expansion that can also cause serious issue and cracks. The underfill material acts as an intermediate between the difference in CTE of the chip and board providing the leeway and flexibility required under thermal stress.

Underfills for BGA packages.

In principle most underfills should work for Ball grid arrays but some popular products are: