EV Propulsion Systems

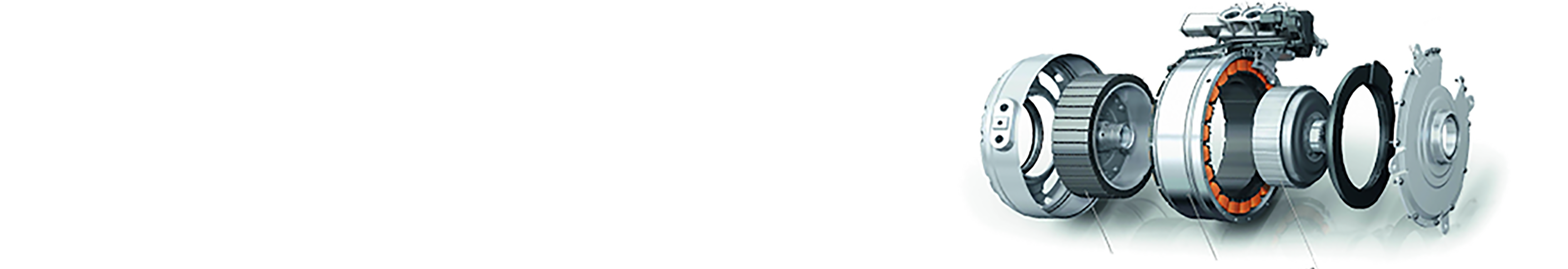

Electric vehicle propulsion systems are a critical component of modern electric vehicles, providing the motive force to propel the vehicle forward. These systems consist of an electric motor, motor control electronics, power electronics, and battery systems that work together to deliver efficient, reliable, and high-performance propulsion.

There are several types of electric motors used in electric vehicle propulsion systems, including AC induction motors, permanent magnet synchronous motors, switched reluctance motors, and IPM motors. Each type of motor has its own unique benefits and drawbacks, making it important to choose the right motor for the specific application.

Motor control electronics and power electronics play a crucial role in electric vehicle propulsion systems, regulating the flow of electricity between the motor and the battery, and controlling the speed and torque of the motor. These systems must be highly efficient and reliable to ensure optimal performance and range.

Battery systems are also a critical component of electric vehicle propulsion systems, providing the energy needed to power the electric motor. Lithium-ion batteries are the most common type of battery used in electric vehicles, offering a high energy density and long lifespan.

There are several types of motors that can be used in electric vehicles. Here is a list of some of the most common types, along with their subtypes:

- DC Motors

- Brushed DC Motor

- Brushless DC Motor

- AC Motors

- Induction Motor

- Permanent Magnet Synchronous Motor (PMSM)

- Interior Permanent Magnet Motor (IPM)

- Switched Reluctance Motor (SRM)

- Electrically Excited Synchronous Motor (EESM)

It's worth noting that some of these motor types can be further classified based on their specific construction or control method. For example, some PMSM motors use surface-mounted magnets, while others use interior magnets. Some AC motors use vector control, while others use direct torque control.

What is an AC motor?

The asynchronous induction motor, also known as the asynchronous AC motor, is a type of AC motor that is commonly used in electric vehicles.

It is a type of induction motor, which means that it uses electromagnetic induction to generate the magnetic field that interacts with the stator winding to produce motion. Unlike synchronous motors such as PMSM and EESM, the rotor of an asynchronous motor rotates at a slightly slower speed than the speed of the rotating magnetic field in the stator. This speed difference, known as slip, is necessary for the motor to operate and produce torque.

Asynchronous induction motors are relatively simple and robust, with a low cost of manufacturing. They are commonly used in electric vehicles due to their high reliability, low maintenance requirements, and good performance characteristics. However, they may have lower efficiency and power density compared to some other motor types, such as PMSM and IPM, and they may require more complex control systems for high-performance applications.

What is a DC motor?

While AC motors are more commonly used in modern electric vehicles, DC motors are still used in some applications. DC motors have been used in electric vehicles for many years and are known for their simplicity, reliability, and low cost.

DC motors have some advantages over AC motors in certain applications, such as in lower power electric vehicles, where they can be a cost-effective solution. They are also well-suited for regenerative braking, which allows them to convert kinetic energy back into electrical energy and store it in the battery.

However, AC motors are generally more efficient and have higher power density than DC motors. They are also easier to control and can provide better performance in high-speed applications. As a result, AC motors are more commonly used in modern electric vehicles, especially in high-performance applications.

Each motor type has its own advantages and disadvantages, and the choice of motor will depend on factors such as cost, performance requirements, and application.

We will focus on some of the main types of motors used in electric vehicles, like:

AC Induction Motor: AC induction motors are the most commonly used motor type in electric vehicles due to their simplicity, reliability, and low cost. They are efficient, have a high power density, and are easy to control. However, they have a limited speed range and require more complex motor control electronics to operate efficiently at higher speeds.

These motors are cheap to make, they don't require rare earth materials and they have exceptional reliability. On the downside they have bigger cooling needs and lower power density and efficiency compared to other motors.Permanent Magnet Synchronous Motor (PMSM): PMSMs are highly efficient and offer a high power density, making them an attractive option for electric vehicle applications. They have a wider speed range than AC induction motors and are easier to control at higher speeds. However, they are more expensive and have a lower torque density than AC induction motors. IPM motors are a subtype.

Switched Reluctance Motor (SRM): SRMs offer a simple and robust motor design, making them attractive for electric vehicle applications. They are highly efficient, have a high power density, and offer a wide speed range. However, they are less common in electric vehicles and can be more challenging to control than AC induction or PMSM motors.

Each type of motor has its own set of advantages and disadvantages, and the choice of motor type depends on the specific needs of the vehicle and its intended use. Some factors to consider include efficiency, power density, torque density, speed range, control complexity, and cost. Ultimately, the motor type must be selected based on the requirements of the vehicle to achieve optimal performance, range, and efficiency.