Gas Detection Tapes

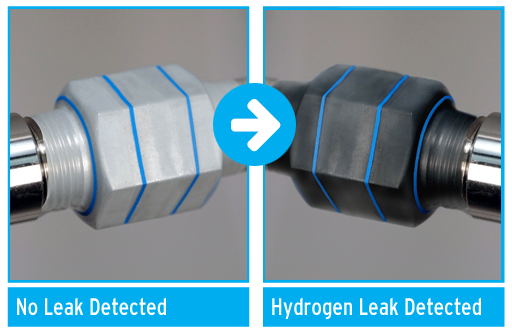

Gas detection is a critical element for the safe manufacturing, handling and use of many industrial gases. Hydrogen Leak detection tapes are taking advantage of chemo-chromic reactions to quickly and efficiently identify leaks. The partial reduction of a catalysed transition metal oxide causes a colour change that makes the leak easy to detect and immediately fix.

Hydrogen's properties make it very hard to detect . It is light, odourless, colourless with a low ignition energy that can create invisible flames. That's why we need a reliable and low cost solution that detects unintended releases from pneumatic systems. Identifying them facilitates corrective actions and is an imperative preventive measure for Hydrogen applications.

Detection tapes are low cost, with a positive indication for both the presence and the absence of hydrogen and can be easily incorporated in any current system without requiring alterations or additional power sources. They are durable, hydrogen sensitive and work with as visual detectors.

The cross linking silicone adhesive ensures a no residue connection that resists UV and most corrosive chemicals and can be wrapped around irregular and unconventional shapes. Since silicone is a hydrogen permeable carrier, the pigment is accessible and changes when the need arises.

These tapes can be used in cabinet connections for routine checks so that leaks will be easily identifies during inspections. They are ideal for hydrogen supply connection points in fuelling stations. Being within visual range of inspection routes they can aid prioritising and expediting repairs based on quantity of alerts and maximising repair efficiency.

LINQTAPE HDT1SR | Hydrogen detection tape

- 100 um film thickness

- Visual H2 leak detection

- 3,000V Breakdown voltage

- 8 weeks

LINQTAPE HDT1S | Hydrogen detection tape

- 1 and 2 inch Options

- Visual H2 leak detection

- Fast and reliable for H2 storage and transportation

- No longer available

DetecTape™ H2 | 10 mil - PF4 | Hydrogen Leak Detection

- Self fusing

- Suitable for all metal substrates

- Perforation every 4 inches

- No longer available

DetecTape™ H2 | 10 mil - PF8 | Hydrogen Leak Detection

- Self fusing

- Chemical and UV resistant

- Perforation every 8 inches

- No longer available

DetecTape™ H2 | 20 mil NP| Hydrogen Leak Detection

- Self fusing 20 mil tape

- Easy to install

- No perforation

- No longer available

Product Selector Guide

| Product name | Description | Film Thickness | Total thickness | Width | Appearance at Room Temperature | Elongation | Polymer Type | Tensile Strength | Breakdown Voltage |

|---|---|---|---|---|---|---|---|---|---|

| Linqtape HDT1SR | Hydrogen Leak Detection Tape | 3.9 mil (99 μm) | 5.9 mil (150 μm) | 22 (mm) | Beige | 700 % | Silicone | 0.32 kg/mm2 | 3,000 V |

Frequently Asked Questions

How fast does the colour change?

The leak rate and concentration determine the speed of color change.The effect is cumulative so even slow or small leaks can lead to significant colour change over a long period of time. Since the reaction is permanent and non reversible after hydrogen is detected, tape replacement is recommended after repair.

How hard is the installation process?

Leak detection tapes can be easily installed by on-site maintenance, inspection teams or equipment operators. They don\'t require any certified training and do not require power to operate. They can be used in unison with existing leak detection tools including sniffers and ultrasonic detectors.

Learn More

Detection Tapes

Detection tapes work based on the principle of colorimetric detection, which is when a substance’s presence and concentration are observed through changes in the color of a solution or a surface of a material. Typically, a chemical reaction produces the change in color, which then “detects” the presence of a certain substance.

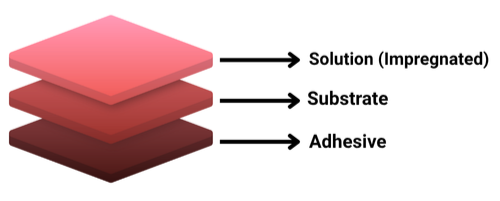

Figure. Colorimetric detection

What's in a Detection Tape?

Detection tapes generally have three components:

- Substrate - Substrates are usually polymer films such as cellulose.

- Solution - A chemical solution that reacts with the substances that is monitored is usually impregnated onto the substrate. This solution, when it chemically reacts, produces the shift in color in detection tapes.

- Adhesive - Detection tape adhesives are usually acrylic or silicone.They are more often pressure-sensitive, particularly in gas detection tapes.

Why Use Detection Tapes?

Alternative Hydrogen Leak Detection Methods

Detection Method | Description |

Bubble Testing | Bubble testing is a simple spot test method with no continuous monitoring at low pressures. |

Thermal Conductivity | Works well in stable environments with minimal temperature change. The background gas needs to have conductivity very different from hydrogen. |

Catalytic Combustion | This method detects the heat of combustion and works well for low concentrations. It is not meant for pure hydrogen. |

Electrochemical Sensors | Those sensors use a liquid electrolyte. Varying temperatures can affects the gas diffusion, making the sensor unreliable. |

Mass Spectrometers | Mass spectrometers are extremely sensitive and expensive. They require skilled operators and may have long response times. |

Gas Chromatographs | Gas Chromatographs are similar to mass spectrometers and have the same "profile" with advantages and disadvantages. |

Ultrasonic | The ultrasonic technology is constantly improving, but it cannot determine the exact location of the leak and whether a combustible mixture is present. |

Semi-Conducting Oxide | The sensor relies on surface effects with a minimum oxygen concentration. While generally reliable, the performance degrades at lower temperatures. |