Fluxophobic Stencil Treatments

Fluxophobic stencil treatments are special coatings applied to stencils used in the printing process of surface-mount technology (SMT) printed circuit boards (PCBs). The goal of these coatings is to prevent the adhesion of flux residue, a byproduct of the soldering process, to the stencil, thus increasing the yield of good PCBs, reducing cleaning time and costs. These coatings are typically applied to the surface of the stencil using a spray, brush or roller and are often used in conjunction with other stencil treatments, such as anti-tarnish and anti-stick coatings, to improve the performance of the stencil and the overall SMT process.

The benefits of using fluxophobic stencil treatments include reducing cleaning time and costs, increased accuracy of the printing process, improved yields of good PCBs, and long-lasting protection of the stencil. The choice of fluxophobic stencil treatment will depend on the specific requirements of the application, such as the type of flux being used and the environment in which the stencil will be used.

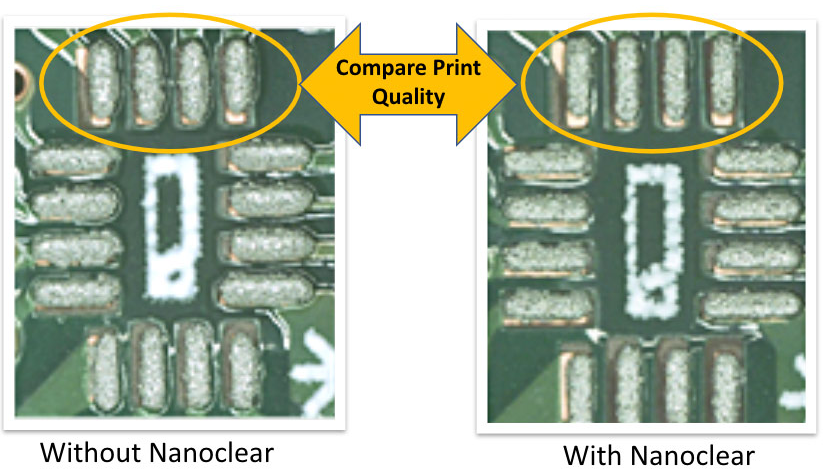

Aculon NanoClear stencil wipes deliver increased output and yield in assembly lines. They reduce the number of under-stencil wipes. Faster release and improved print resolution is achieved. NanoClear stencil technology has been proven on the market and now with a new and improved formula outperforms the competition in terms of performance and ease of use.

NanoClear Fluxophobic Stencil Treatment Wipes

- Best-in-class stencil treatment technology

- Better quality printing

- Reduce underside cleaning

NanoClear Test Pen

- Best-in-class stencil treatment technology

- Simple and effective test

- No training required

Frequently Asked Questions

What is a fluxophobic stencil treatment?

A fluxophobic stencil treatment is a special coating applied to stencils that are used in the printing process of surface-mount technology (SMT) printed circuit boards (PCBs). These coatings are designed to prevent the adhesion of flux residue, a byproduct of the soldering process, to the stencil.

The goal of fluxophobic stencil treatments is to improve the printing process, increase the yield of good PCBs and reduce the cleaning time and costs.

How is a fluxophobic stencil treatment applied?

Fluxophobic stencil treatments are typically applied to the surface of the stencil using a spray, brush or roller. They can also be applied by dipping the stencil in a solution containing the fluxophobic treatment, allowing the stencil to dry and then rinsing it.

Wipes are one of the most popular options since you can wipe the surface that you are trying to enhance.

Learn More

The importance of Stencil treatments for SMT processes.

Fluxophobic stencil treatments are special coatings applied to stencils that are used in the printing process of surface-mount technology (SMT) printed circuit boards (PCBs). These coatings are designed to prevent the adhesion of flux residue, a byproduct of the soldering process, to the stencil. The goal of fluxophobic stencil treatments is to improve the printing process, increase the yield of good PCBs and reduce the cleaning time and costs.

Fluxophobic stencil treatments are typically applied to the surface of the stencil using a spray, brush or roller. They are often used in conjunction with other stencil treatments, such as anti-tarnish coatings and anti-stick coatings, to improve the performance of the stencil and the overall SMT process.

The main advantage of fluxophobic stencil treatments is that they can greatly reduce the amount of cleaning that is required after the printing process. This can lead to cost savings, as well as faster turnaround times for PCB production. Additionally, fluxophobic stencil treatments can also improve the overall accuracy of the printing process, which can lead to higher yields of good PCBs.

It's worth noting that the choice of fluxophobic stencil treatment will depend on the specific requirements of the application, such as the type of flux being used, the environment in which the stencil will be used, and the cost of the treatment. Some of the most common fluxophobic stencil treatments include silicone, PTFE, and Parylene.