Rubber Cleaning Sheets

Rubber cleaning sheets are the most popular, safe and flexible cleaning solution for semiconductor mold cleaning. Mold equipment accumulates stains and residues after a certain amount of production shots. If these are left alone the final molded products will slowly become problematic, defective and unsuitable for production. That's why all mold equipment users and manufacturers implement a cleaning schedule between production runs to ensure a smooth, clean and waste free process.

Rubber cleaning sheets are very easy to introduce between production runs with minimal downtime that ensures a speedy, deep cleaning that doesn't slowdown production cycles. Cleaning sheets are suitable for compression cleaning, don't require dummy leadframes and preheating and can reach down and clean the deepest gate areas.

RCS 320 | Rubber Cleaning Sheets

- Optimal cleaning performance

- Good flow characteristics

- No mold abrasion

- 8 weeks

RCS 550 | Rubber Cleaning Sheets

- Low torque, suitable for intricate cavities and air vents

- No mold abrasion & corrosion

- Minimal odor

- 12 weeks

RCS 560 | Rubber Cleaning Sheets

- High torque, high cleaning efficiency for deep residues

- No mold abrasion & corrosion

- Minimal odor

- 12 weeks

RCS 400| Rubber Cleaning Sheets

- Carcinogen free

- Compression Grade

- No mold abrasion or corrosion

- In stock

RCS 530 | Rubber Cleaning Sheets

- Prestage cleaning

- Dissolving characteristics

- No mold abrasion

- In stock

RCS 620 | Rubber Cleaning Sheets

- No leadframe or preheat

- Excellent effectiveness

- For cavities and air vents

- 6 weeks

RCS 880 | Rubber Cleaning Sheets

- Great releasing properties

- No leadframe required

- Excellent for vents and cavities

- 6 weeks

Product Selector Guide

| Product Name | Technical Specifications | Comments | ||||

|---|---|---|---|---|---|---|

| Package | Application method | Formaldehyde | Mold Temperature (°C) | Curing Time (min) | ||

| RCS 320 | Rubber Sheets | Compression | N/A | 160 - 190 | 4 - 6 | Optimal cleaning performance, less smell and fumes, suited for production of ICs, diodes, transistors, and LEDs. |

| RCS 530 | Rubber Sheets | Compression | N/A | 160-190 | 4 - 6 | Prestage cleaning sheet, first stage stain dissolvers, strong odor and minimal fumes |

| RCS 550 | Rubber Sheets | Compression | N/A | 165-175 | 5-7 | Lower torque rubber cleaner which remains soft during curing, allowing it to flow into the more intricate mold areas for a more thorough clean especially in the air ducts where your client is facing residue built up |

| RCS 560 | Rubber Sheets | Compression | N/A | 165-175 | 5-7 | Higher torque rubber cleaner which exerts stronger mechanical force during the molding and curing process, leading to more aggressive cleaning targeting the deep residue build up in the air vents |

| RCS 400 | Rubber Sheets | Compression | N/A | 165 - 200 | 5 - 10 | Carcinogen-free, safe and easy to use. Relatively low to medium viscosity and suited for IC, Semiconductors and Discrete molding processes. |

| RCS 620 | Rubber Sheets | Compression | N/A | 170 | 2 - 5 | Mainly used to clean mold cavities, air vents, cavities gates and the mold surface in a single step. Fast cure, nonexistent odor. |

| RCS 880 | Rubber Sheets | Compression | N/A | 170 | 2 - 5 | Specially formulated compound designed for cleaning mold corners and thin gate areas easily. |

*Compression cleaning products are suitable for transfer molding equipment. Do not confuse the application method with the epoxy molding equipment.

Learn More

Mold Cleaning Rubber Sheet - CHEMLINQ ™

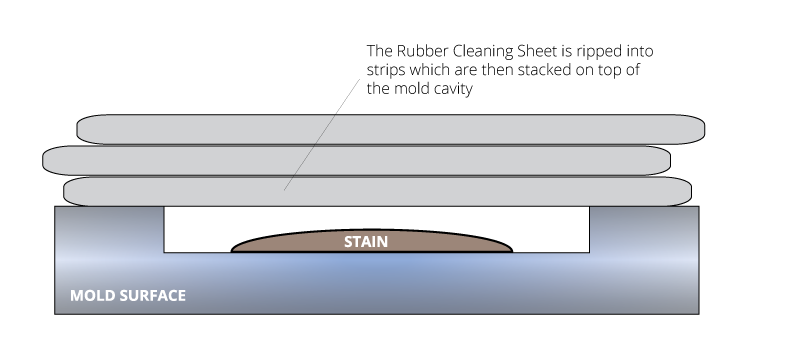

Because Melamine takes a lot of shots to be effective, is hard to remove from the mold cavity, and gives of formalin vapors that cause cancer, and because manually rubbing at stains with a copper brush is impractical, a new trend within the semiconductor industry is to use unvulcanized rubber compounds .

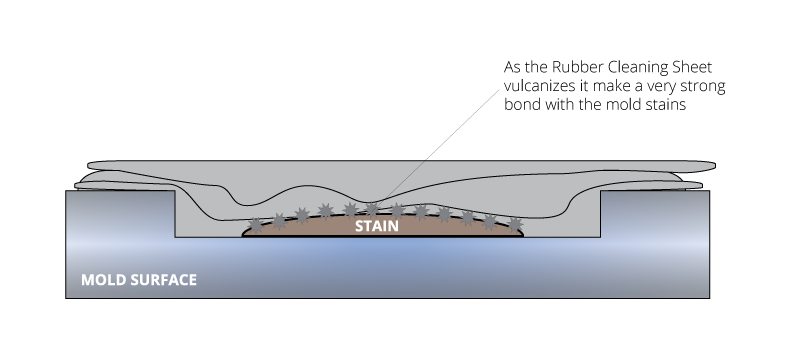

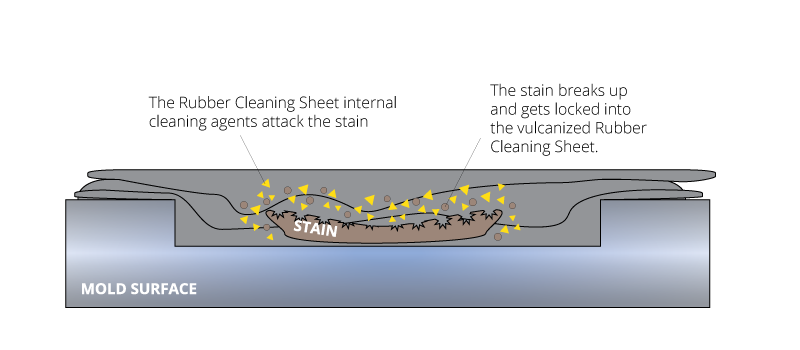

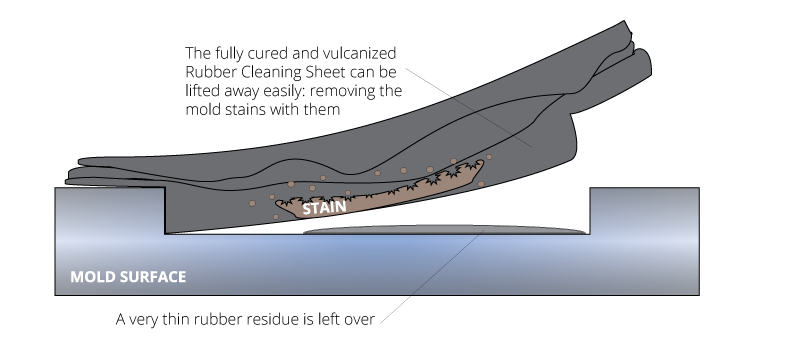

The unvulcanized rubber compound is then vulcanized in the mold in a process which captures and integrates most mold stains residues. When the now vulcanized rubber compound is removed from the mold cavities it then takes the mold stain with it, leaving a very effectively cleaned mold die surface.

- Use your standard molding conditions

- Place rubber sheets over the cavities and runners

- Close the mold and cure for 5 minutes

- When press opens, remove the cured sheets

- Check sheets and mold cavities for stain

- Repeat the above steps until the mold is completely clean & stains are no longer transferred to the rubber sheet

- Remove the residual rubber film with a shot of compression or transfer melamine

By adding additional cleaning agents such as an imidazole and an imidazoline to the unvulcanized rubber the stains and residue from even the toughest epoxy compounds like biphenyl or dicyclopentadiene epoxy resin can be completely removed. Rubber cleaning sheets can be used with fewer shots, are easier to remove, and are super effective at the right temperature.

However, effective as it is, even rubber has drawbacks. It leaves a very fine layer of residue after the cleaning process. Each of these has their own advantages and disadvantages, but, when used correctly they all are capable of cleaning your molds. When used in combination, they may be even more efficient than one method alone.

Melamine Cleaning Compound is relatively cheap, but requires more shots to be effective and is harder to remove so has overall poorer workability. The fact that it has formaldehyde in its contents makes it more difficult to ship and more dangerous to use. CAPLINQ will continue to research and develop more effective and formaldehyde-free Melamine Cleaning Compounds in the future.

Rubber Cleaning Sheets, on the other hand, gives off fewer vapors, are formaldehyde-free, carcinogen-free, and are more effective with fewer shots, and being easy to removes has excellent workability. However, it does leave a thin rubber residue after use. So, in both cases, the cleaning process is achieved by a combination of chemical and mechanical scrubbing.