Coatings, powders & Resins

Coating powders, and liquid resins for casting potting and encapsulation are a category of coating materials designed to encapsulate the part. The purpose of the coating or encapsulation can be decorative, in the case of different colors, but it can also be functional in that it also provides electrical insulation or mechanical protection. Powders, varnishes, and paints are all encapsulation methods that speak more about the application method than the chemistry type.

Coating powders can be broadly defined into two broad chemistry types: thermoplastics and thermoset plastics. Each type has its pros and cons and can be further subdivided into different chemistry types and then finally defined by the end-application and desired final properties.

Please continue to our Learn More section to learn more about the kinds of coating, paint and varnish types, their application methods and to understand how CAPLINQ can help you to select and order the proper coating powder, paint or varnish that is right for your application.

Frequently Asked Questions

Frequently Asked Questions about Coating Powders

What are the main types of coating powder?

Coating powders can be broadly divided into thermoplastics which include polyethylene (PE) and PVC and thermoset plastics which include polyester and epoxy coating powders. Both have their pros and cons.

Learn More

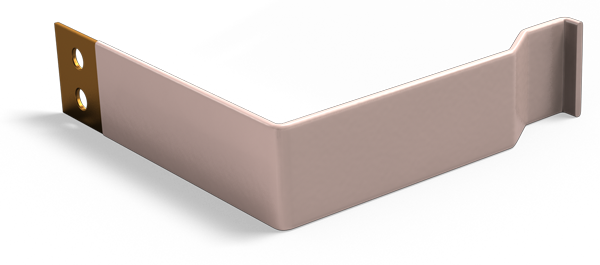

Epoxy Coating Powders for Busbar Coating, Switchgear Equipment and High Voltage Fuses

For many years CAPLINQ has supplied a range of epoxy coating powders developed for medium voltage (600V – 38,000V) bus bar and switch gear applications. CAPLINQ is one of the few epoxy coating powder manufacturers with "switch panel-rated" material, meaning that their epoxy coating powders are qualified for use in Power Distribution Switch Boards. Given the critical nature of the application, the time and costs involved to pass UL-certification, major Power Management Companies reply on CAPLINQ and their family of UL-listed epoxy coating powders. All the products offered by CAPLINQ for busbar applications are UL-listed.

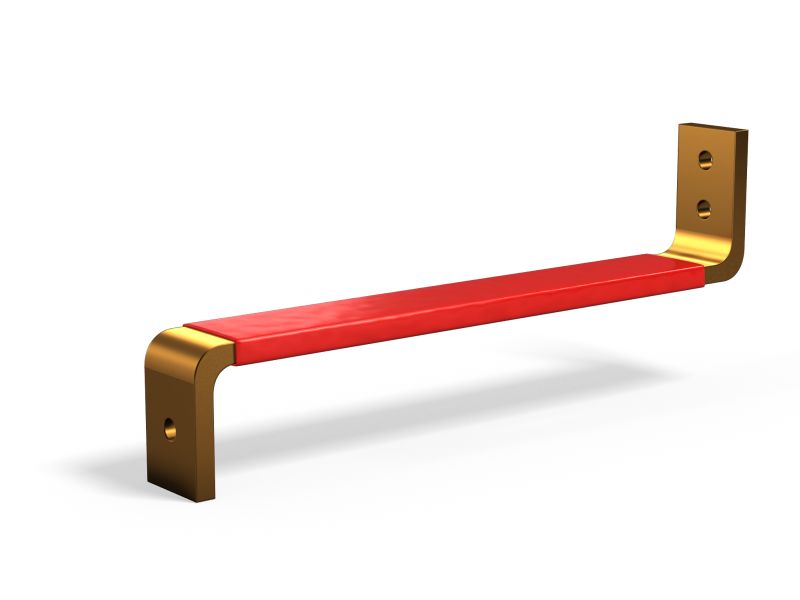

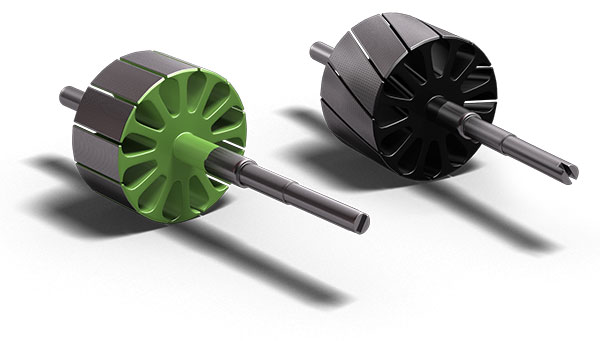

Epoxy Coating Powders for Slot Insulation of Motor Iron Armatures and Stators

CAPLINQ supplies a range of epoxy coating powders developed for motor iron armatures. From incredible bed life epoxy powders to high productivity coating powders to Class H-rated coating powders, CAPLINQ has an epoxy coating powder to meet every type of motor armature insulation application. All the products offered by CAPLINQ for motor iron armature applications are UL-listed.

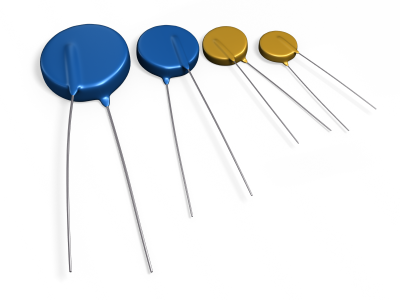

Epoxy Coating Powders for Resistors, Capacitors, Varistors and Passive Electronics

CAPLINQ supplies a range of epoxy coating powders developed for electrical insulation of passive electronic devices including resistors, varistors and capacitors. From incredible thermal cycle materials for Class 1 rated Ceramic Capacitors, to low cost epoxy coating powders for film wrap capacitors, CAPLINQ products pioneered this industry and continue to push the envelope for the best performing materials on the market today. Most of the products offered by CAPLINQ for passive electronics have a UL-listing.

Epoxy Coating Powders for Toroids, Magnetic and Powder Cores

CAPLINQ supplies a range of epoxy coating powders developed for toroids, magnetic cores and powder cores. These products are low shrinkage and low moisture absorption coating powders which maintains the stability and inductance values of the toroid cores. These products are suitable for Molypermalloy (MPP), Iron, Sendust and other alloy powder cores. Most of the products offered by CAPLINQ for powder cores have a UL-listing.

Epoxy Coating Powders as Epoxy Binder Resin for Pot Cores

CAPLINQ supplies epoxy coating powders developed specifically to act as an epoxy binder resin for pot cores used in inductor motors. These products have excellent green strength to allow the transport from the press to the oven. Once cured, these pot cores can be used at temperatures up to 180°C and maintain their mechanical properties as well as their magnetic properties.

Methods of Applying Coating Powders

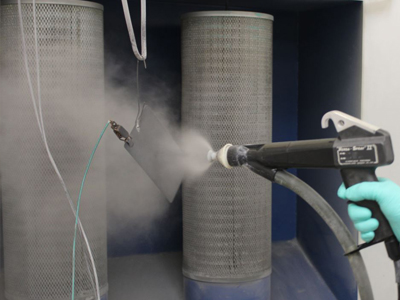

Electrostatic Spraying of Epoxy Coating Powder

Coating powders can be applied using an electrostatic gun. In these cases, the powder is positively charged and the part being coated in negatively charged. This allows a thin, uniform coating to be applied to the part.

The advantage of this approach is that the powder can be wiped off and reapplied if the coating is not correct, or if the masking was done incorrectly. Since the coating powder is only attached by a static charge, it can easily be wiped off. Furthermore, the thickness of the coating can be quite uniform and can be increased or decreased based on the charge applied.

Once the part is electrostatically coated, it is moved to an oven, where the coating powder is cured in place, leaving a smooth, uniform coating over the part.

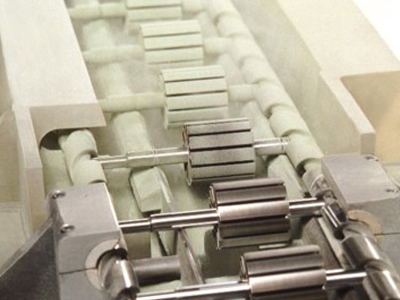

Electrostatic Fluidized Bed Application of Coating Powder

Applying the coating powder using an electrostatic fluidized better is a very practical way to apply a uniform powder coating on motor iron armatures.

Similar to the electrostatic spray application, the part and powder are charged, and the powder is applied by forwarding the parts on a rotating screw over the fluidized bed. The powder adheres to the motor armature by static electricity. As the parts roll past the fluidized bed, a brush is applied to the outside of the motor iron, removing the coating powder from the outside of the motor iron where it is nopt wanted.

Once the coating powder has been removed, the parts are rolled over an induction cure copper element where the motor armatures are exposed to temperatures of up to 240°C for a few seconds to fix and cure the coating powder in place.

Coating Powder for Motor Iron Armature Insulation

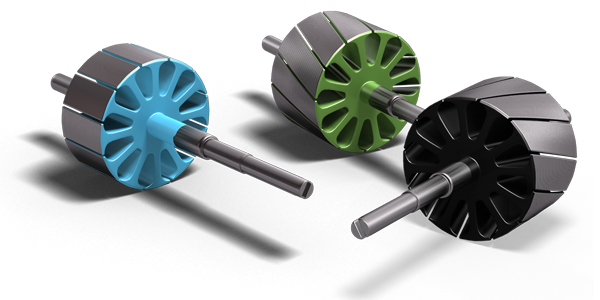

CAPLINQ offers a range of coating powders for slot insulation including blue, black and green variants and Class H candidates.

Technical Papers & Brochures

CAPLINQ offers a wealth of Technical Papers, Marketing Brochures, Technical Data Sheets and SDS covering our coating powders, paints and varnishes.

Read our Blog on Coating Powders

We try to post as much information as we can on our blogs, to help you find more relevant information about how to select, use and apply coating powders, varnishes and paints.

Coating Powders for Busbar Insulation

CAPLINQ offers a range of epoxy coating powders for busbar and power distribution insulation.