Light Emitting Diodes

Light emitting diodes are light emitting dies that get their color or hue through the phosphor that is coated on top of the die. They are typically blue tinted and are getting their color from a combination of the phosphor, the die light intensity and the overmolded optoelectronic molding compound. There are multipl LED types for a huge variety of applications, ranging from simple through hole mono chrom LEDs to backlight, organic, miniLEDs and industrial baylights. All of these LED types have the same principle but completely different application and reliability requirements.

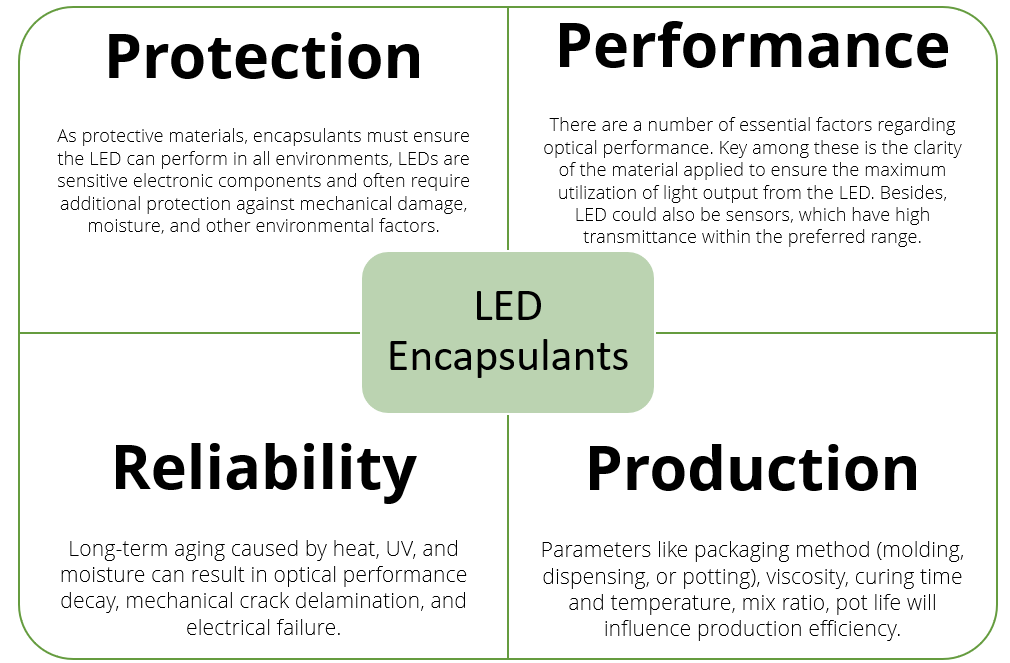

General Considerations For LED Encapsulants

As LED encaplants, besides general consideration of packaging materials, optical performance with long-term reliability is specially emphasized.

Challenges & Solutions

| Challenges | Problem Description | Encapsulation Solutions |

|---|---|---|

| Light Extraction |

|

|

| Delamination |

|

|

| Thermal-Yellowing |

|

|

| UV-Yellowing |

|

|

| Aging/Lifetime |

| Above All |

| Sensor Transmission |

|

|

LED Product overview

Monochrome LEDs | HD RGB LEDs | White LEDs | |||||

Product | TC-8020 (Star Product) | TC-8040 | TC-7600 (Popular Product) | TC-7800 (In Development) | TC-8030 | TC-8060 (Popular Product) | TC-8090 (In Development) |

Summary |

|

|

| ||||

Applications | 7-segment LED display, compact LED indicator, monochrome Chip LED, photo-link | High density (fine-pitch) RGB LED display | Decorative White LED | Backlight | High Reliability Backlight | ||

Light Decline Aging Test | - | Medium 10-50% RT*20mA*500hrs | Medium 10-50% RT*5mA*1000hrs | Low <50% RT*20mA*500hrs | High <10% RT*5mA*1000hrs | ||

Reliability Tests | Reflow, TCT, 85℃@85%RH | Reflow, TCT, 85℃@85%RH, PCT | Reflow, TCT, 85℃@85%RH | ||||

Highlight | Low stress and filter versions available | High reliability Mid blue-ray decay | Low blue-ray decay | Low blue-ray decay High anti-yellowish | Low cost | Low blue-ray decay | Low blue-ray decay Anti-moisture |

Comparable | XX-18, XX-1012, XX-8524 | XX-600H | XX-600H | XX-600H-94000 | XX-1014, XX-8524 | XX-1000, XX-814, XX-97 | XX-1000, XX-814, XX-97 |

Child Product | TC-8020L/LS low-stress TC-8020T-SR self-release version TC-8050 for large package |

|

|

| TC-8034 with low decay TC-8036 with low decay | Low CTE product TC-9000T with transparent filler TC-8060 IMP low modulus version |

|

Die Attach For LEDs

LOCTITE ABLESTIK ABP 8037TI silver-filled die attach adhesive paste is specifically designed to attach small diodes in high volume manufacturing. Even more specifically, it is the highest volume silver-filled die attach paste for high reliability LED attach and manufacture when using small die on Au-finished leadframes. Used in high-volume manufacturing throughout China and Malaysia.

Also extremely popular:

LOCTITE ABLESTIK 84-1LMISR4 is a manufacturer's product of choice, can be used for LED applications and like most epoxies it is suitable for Copper substrates.

One alternative:

LOCTITE® ABLESTIK ABP 8035M is a non-conductive clear silicone designed for high brightness LED die attach applications.

Non conductive option:

LOCTITE ABLESTIK QMI536NB creates packages and devices that have high resistance to delamination and popcorning after multiple exposures to lead-free solder reflow temperatures. It has good optical performance with high transmittance, Optical Density and HRI and is a great solution for ASIC attach and LED attach.