Thinners

Conformal coating thinners are specially formulated solvents that help you fine-tune how a conformal coating behaves during application. By reducing viscosity, they make the coating easier to brush, dip, or spray, allowing it to level out smoothly and create an even, defect-free finish.

Beyond just thinning the material, the right thinner also improves flow, helps prevent bubbles or streaking, and ensures the coating adheres properly to delicate electronic assemblies. When used correctly, thinners support the coating’s ability to protect circuits from moisture, dust, and other environmental stresses without compromising its electrical insulation or long-term reliability.

Humiseal Thinner 521EU

- RoHS Directive 2002/95/EC compliant

- For use with HumiSeal conformal coatings

- Ensures proper viscosity adjustment

- In stock

HumiSeal Thinner 64

- RoHS Directive 2015/863/EU compliant

- Ensures proper viscosity adjustment

- For use with HumiSeal 2A64

- 6 weeks

HumiSeal Thinner 73

- RoHS Directive 2015/863/EU compliant

- Ensures proper viscosity adjustment

- For use with 1B73 and 1A20

- 6 weeks

HumiSeal Thinner 503

- RoHS Directive 2015/863/EU compliant

- Ensures proper viscosity adjustment

- Compatible with HumiSeal 1B12, 1B31, 1B66, and 1B73

- 6 weeks

HumiSeal Thinner 505

- RoHS Directive 2015/863/EU compliant

- Ensures proper viscosity adjustment

- Compatible with HumiSeal 1R32 and 1R32A-2

- 6 weeks

HumiSeal Thinner 521

- RoHS Directive 2015/863/EU compliant

- Ensures proper viscosity adjustment

- Compatible with multiple HumiSeal conformal coatings

HumiSeal Thinner 600

- RoHS Directive 2011/65/EC compliant

- Compatible with multiple HumiSeal conformal coatings

- Specialty thinner

- 6 weeks

HumiSeal Thinner 602-245

- RoHS Directive 2011/65/EU compliant

- For acrylic conformal coatings

- Ensures proper viscosity adjustment

- 6 weeks

HumiSeal Thinner 604

- RoHS Directive 2011/65/EC compliant

- Specialty thinner

- For use with 1B31EPA and 1B73EPA

- 6 weeks

HumiSeal Thinner 673

- RoHS Directive 2015/863/EU compliant

- For use with acrylic conformal coatings

- Ensures proper viscosity adjustment

- 6 weeks

HumiSeal Thinner 701

- RoHS Directive 2011/65/EC compliant

- For use with multiple HumiSeal conformal coatings

- Ensures proper viscosity adjustment

- 6 weeks

HumiSeal Thinner 789

- For use with LTX series of conformal coatings

- Low odor

- No aromatic compounds

- 6 weeks

HumiSeal Thinner 905

- For rapid cure applications

- Fast evaporation rate

- For faster recoat process

- 6 weeks

HumiSeal Thinner 535

- RoHS Directive 2015/863/EU compliant

- Ensures proper viscosity adjustment

- Compatible with 2A53 conformal coating

- 6 weeks

Frequently Asked Questions

What are Conformal Coating Thinners?

Conformal coating thinners are solvent blends designed to reduce the viscosity of liquid conformal coatings, improve flow, and support proper application by spraying, dipping, or brushing. They help achieve smooth, defect-free films without compromising coating performance.

Why are thinners used with conformal coatings?

Thinners are used to adjust viscosity, enhance leveling, prevent bubbles, maintain consistent film thickness, and ensure that coatings apply evenly across complex electronic assemblies. They are also used for cleaning tools, spray equipment, and lines when compatible with the coating chemistry.

What types of thinners are available?

Thinners are formulated to match specific coating chemistries. Common types include acrylic thinners, polyurethane thinners, silicone thinners, and epoxy thinners. Each type has a specific evaporation rate and compatibility profile to ensure proper application and coating performance.

Can any thinner be used with any conformal coating?

No. Thinners must be chemically compatible with the coating. Using an incorrect thinner can cause whitening, poor adhesion, incomplete cure, or material defects. Always use the thinner recommended by the coating manufacturer to maintain product integrity.

How do thinners affect the application process?

Thinners adjust the coating’s flow and atomization during application. For spraying, they help achieve fine atomization and even coverage. For dipping, they maintain consistent withdrawal viscosity. For brushing, they reduce streaking and improve leveling.

What is the role of evaporation rate in thinners?

The evaporation rate determines how quickly a thinner flashes off during application. Fast-evaporating thinners support quick drying, while slower thinners improve leveling and help prevent bubbles. Choosing the right rate depends on the coating method and environmental conditions.

Can thinners be used for cleaning equipment?

Many thinners can be used to clean spray guns, pumps, brushes, and coating lines, but not all are intended for cleaning purposes. Some are viscosity reducers only. Always verify whether the thinner is compatible and safe for cleaning to avoid contamination or damage.

What safety precautions should be taken when using thinners?

Thinners are volatile solvents and should be used with proper ventilation, PPE, and safe handling procedures. Containers must be kept sealed to prevent evaporation, and waste should be disposed of according to local environmental regulations.

Learn More

Conformal coatings are formulated with a specific viscosity optimized for certain application methods. However, environmental conditions, coating thickness requirements, equipment setups, or storage time can make the coating too thick for proper use. This is where thinners come in.

Why Thinners Are Used

- Conformal coating thinners allow you to:

- Reduce viscosity for spray, dip, or selective-coating equipment

- Improve leveling and flow-out to avoid bubbles, orange peel, and streaks

- Control film thickness for precise technical requirements

- Extend pot life during long production runs

- Clean tools, lines, and equipment when compatible with the coating chemistry

- Restore aged coatings that have partially evaporated or become too thick

Important thinners properties per conformal coating chemistry

Different coating conformal coating chemistries require different thinner properties. For different

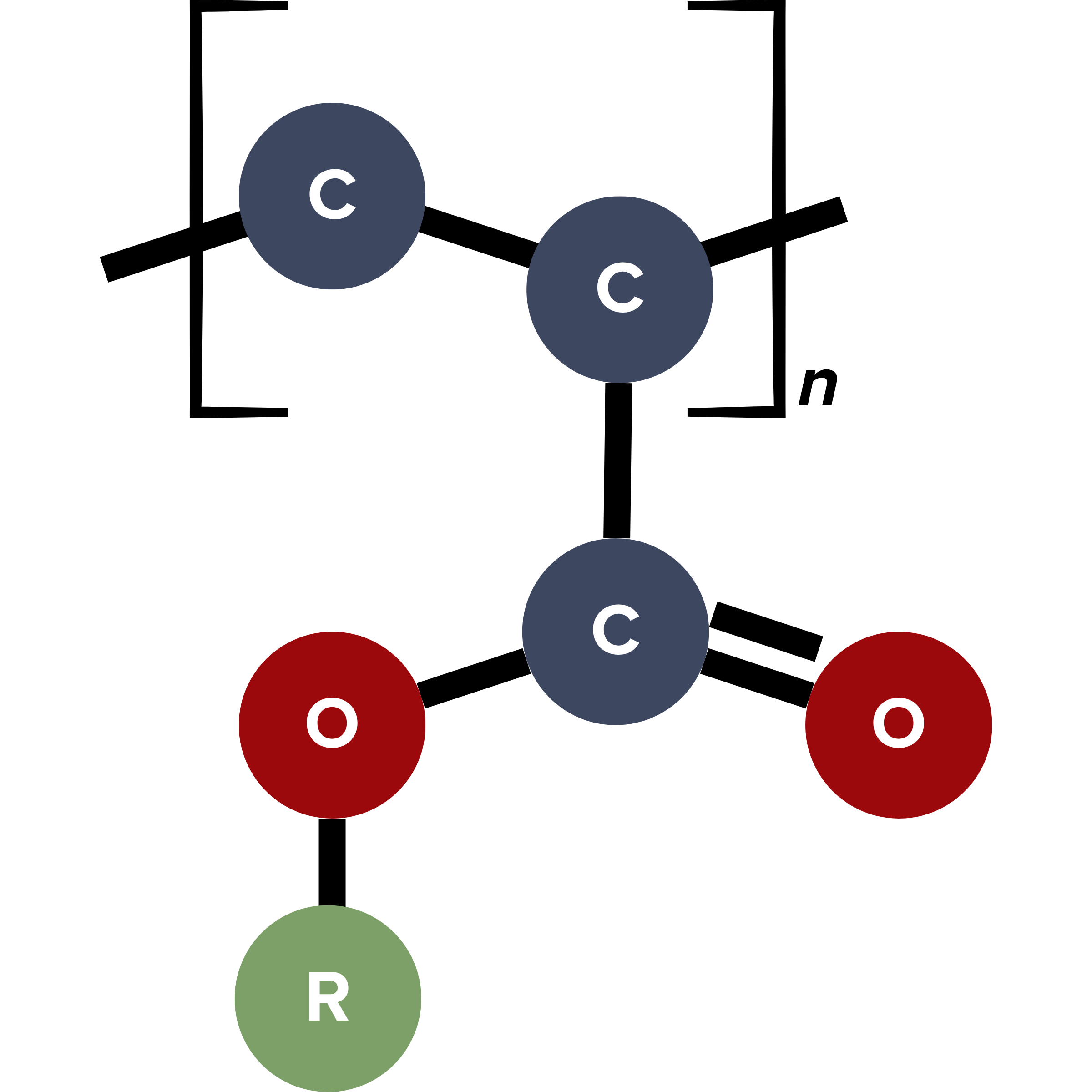

Acrylic

- Fast, clean evaporation rate

- High solvency strength for acrylic resins

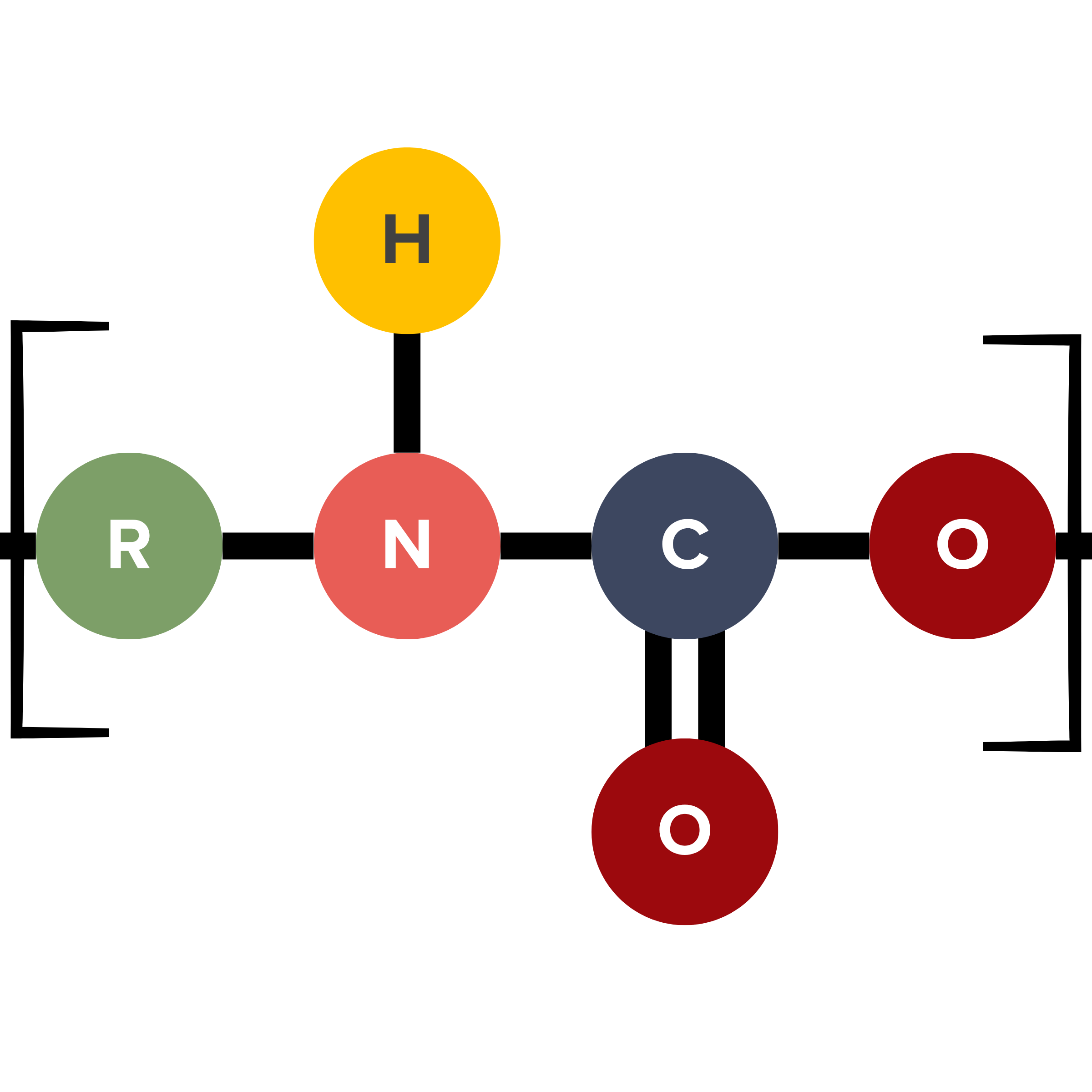

Urethane

- Controlled/medium evaporation rate

- Isocyanate-safe formulation

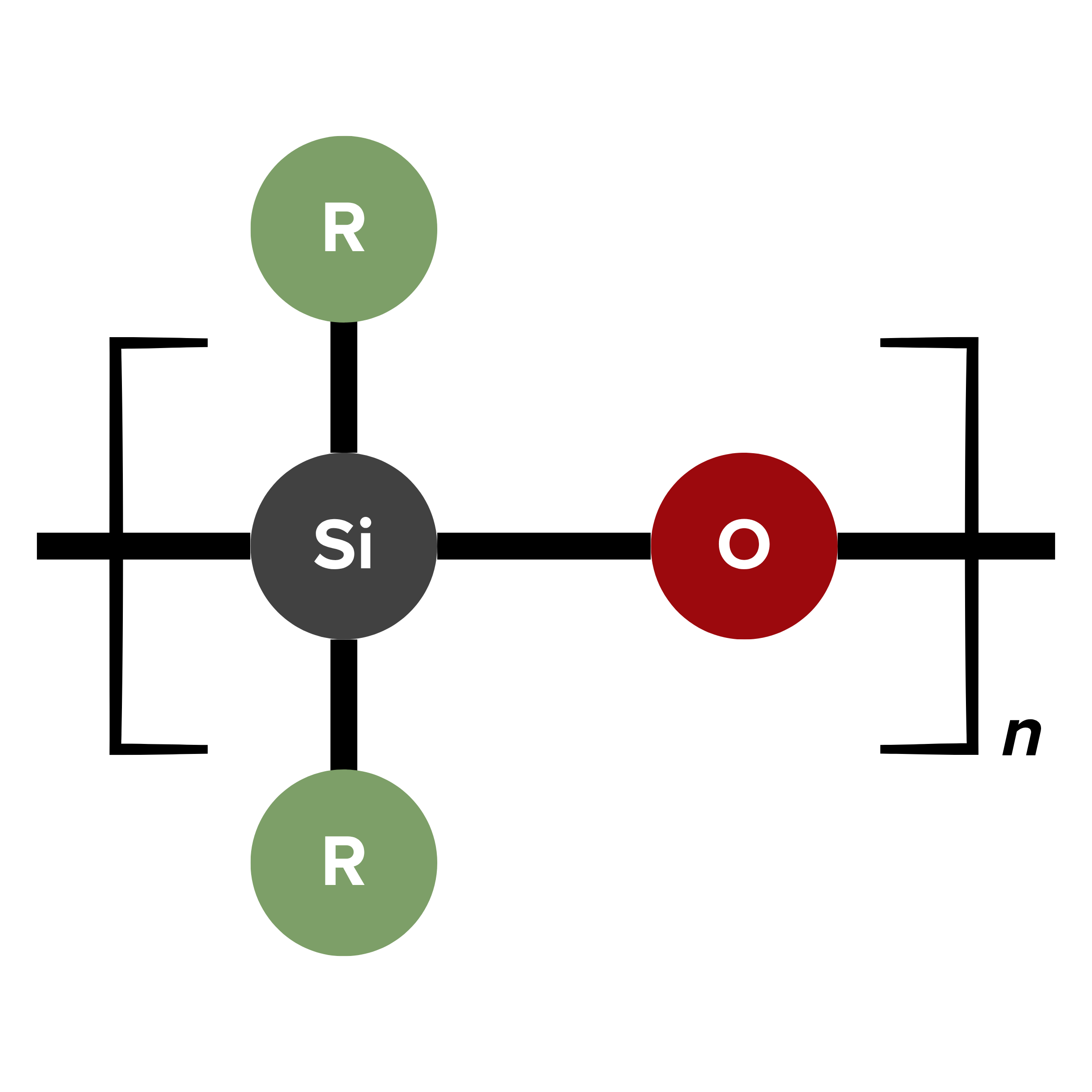

Silicone

- Slow to moderate evaporation rate

- Low polarity & compatibility with silicone oils/resins

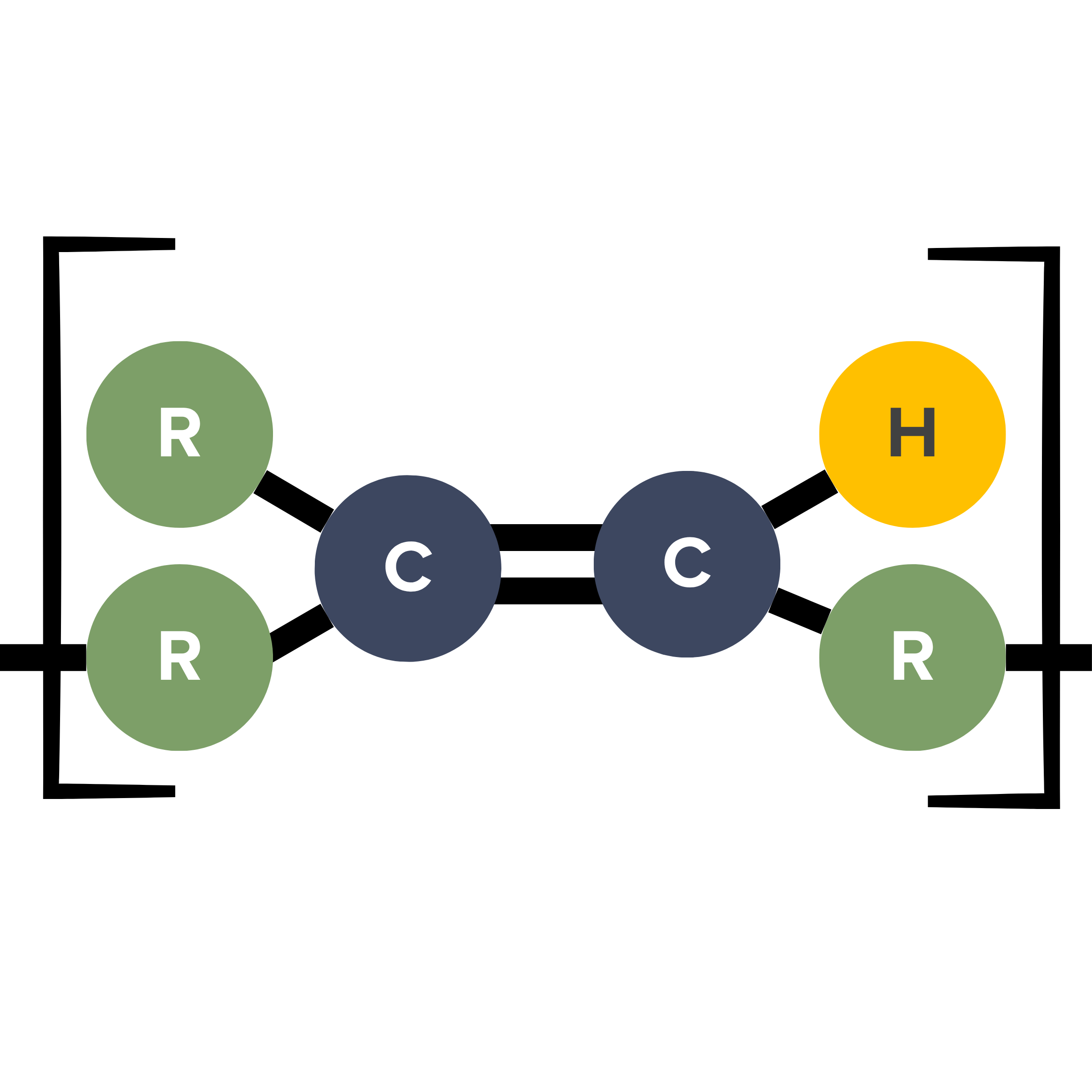

Rubber

- Strong solvency for elastomeric polymers

- Plasticizer-compatible formulation

How Thinners Affect Application

- Achieve consistent atomization

- Prevent dry spray and overspray roughness

- Improve edge wetting on densely populated boards

- Maintain consistent withdrawal viscosity

- Reduce runs or dripping

- Ensure uniform coating thickness

- Improve flow and minimize brush marks

- Adjust open time for larger boards or rework

Equipment Cleaning vs. Viscosity Adjustment

Some thinners serve dual purposes—both thinning and equipment cleaning. Others are cleaning-only solvents designed to remove uncured coating residue from spray guns, pumps, or lines.

Always check labeling to avoid accidentally introducing contaminants into a production line.