Schottky Diodes

.png)

How do regular Si diodes work?

Most ordinary diodes are built from silicon. They are formed by joining two types of semiconductor materials:

- n-type semiconductor – contains extra electrons (negative charge carriers).

- p-type semiconductor – contains “holes” or missing electrons (positive charge carriers).

.png)

.png)

How the diode responds depends on the direction of the applied voltage. In forward bias, the positive terminal is connected to the p-type side (anode) and the negative terminal to the n-type side (cathode). The external voltage reduces the depletion barrier, allowing current to flow. In reverse bias, the terminals are flipped. The depletion region widens, strengthening the barrier and preventing current flow.

Physically, diodes come in different sizes but are usually enclosed in a cylindrical molding compound with a stripe on one end (negative end), and leads on both ends of the cylinder (with the exception for LEDs, or light emitting diodes). To learn more about Si diodes in-depth, you may visit our main application page on diodes.Forward Bias

Diode acts as a conductor.Reverse Bias

Diode acts as an insulator.Schottky Diodes vs. Regular Si Diodes

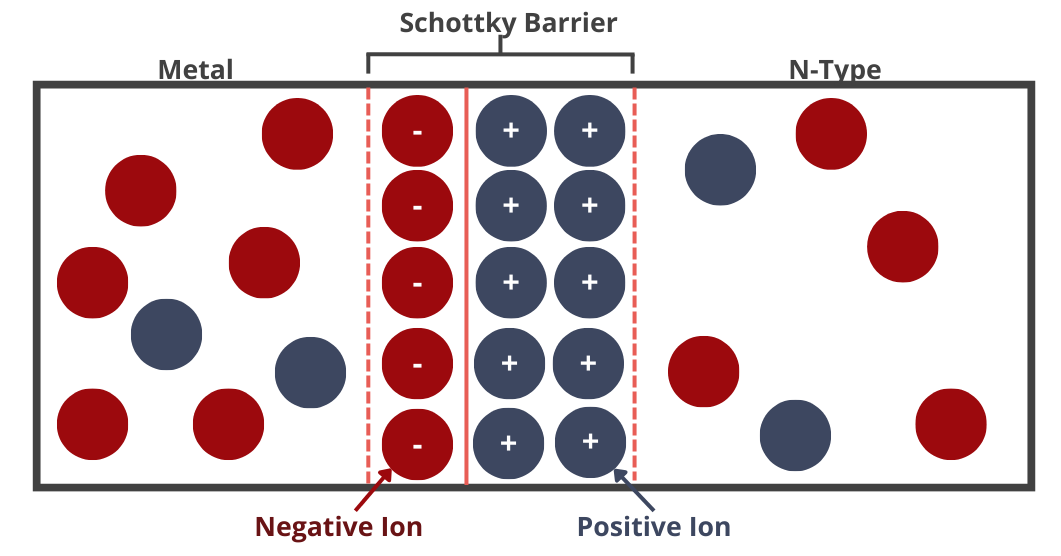

Schottky diodes still function like any other diode but they are unique in such a way that they do not have a P-N junction. Instead, Schottky diodes have a metal compound connected to an n-type semiconductor (metal-semiconductor junction) and a Schottky barrier.

A Schottky barrier, in simpler terms, is an electrostatic depletion layer. When a metal directly comes into contact with an n-type semiconductor, the Fermi levels (i.e., highest energy level occupied by electrons at absolute zero) of these materials align, causing a bend in the electronic band, creating a potential energy barrier for the electrons in the metal-semiconductor junction.

The majority carrier present in this diode is electrons and they have virtually no holes, which is why they are considered as unipolar device (i.e., diodes that function with only one type of charge carriers), making them function as a rectifier, which is an electrical device that converts alternating current to direct current.

.png)

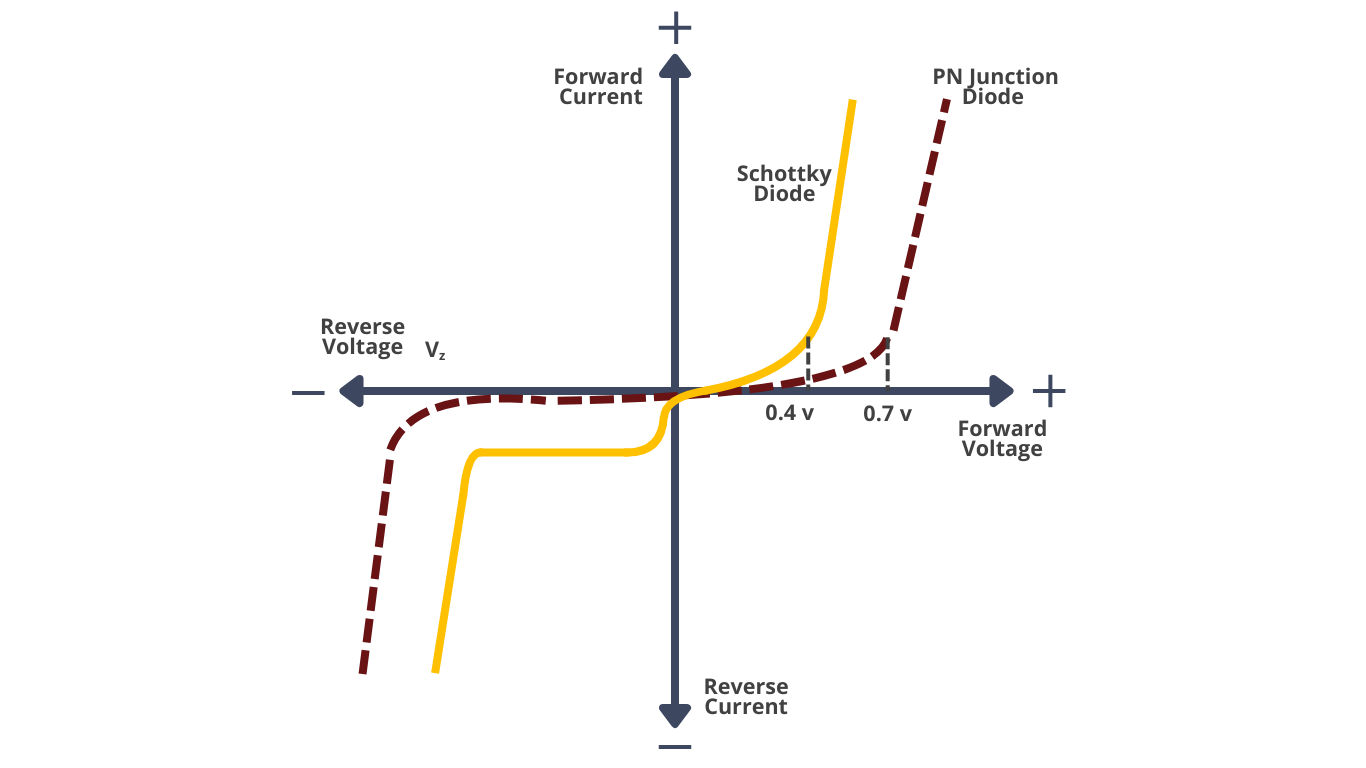

Figure. Schottky Diodes vs. Regular P-N Diodes

Figure. Metal-Semiconductor Junction in Schottky Diodes

Figure. Forward Voltage of Regular & Schottky Diodes

Figure. Forward Voltage of Regular & Schottky DiodesBecause of how Schottky diodes are structured, the forward voltage is lower compared to traditional Si diodes (0.2 ~ 0.3V) and its switching speeds are faster. Faster switching is made possible by the diode’s unipolar nature wherein there is no accumulation of minority carriers, which is the primary cause of delay in regular diodes with p-n junctions.

To better visualize this, imagine that regular diodes are like a busy intersection with traffic lights. When the light is green, current flows easily. But when the light changes, some "traffic" (carriers) get briefly stuck, creating a slight delay before the flow can reverse.

Schottky diodes, however, are a one-way street for current. Because of their unique metal-to-semiconductor junction, they have no "traffic lights" or stranded carriers. This allows for instantaneous switching and significantly faster performance, making them ideal for high-frequency applications.

Why does lower forward voltage matter?

A lower forward voltage means that there is a lower voltage drop across the diode, making energy consumption more efficient. Less energy is dissipated as heat and power loss is kept at a minimum. This low forward voltage also makes Schottky diodes the ideal material for low-voltage applications.Why is faster switching speed important?

Faster switching speeds prevent charges from accumulating, allowing Schottky diodes to instantaneously switch on and off with little to no delays. Similar to having a lower forward voltage, faster switching speeds also allow the diode to use energy efficiently and ensure accurate signal processing.

While Schottky diodes may seem like an upgrade from regular silicon diodes, it also has its fair share of disadvantages:

Leakage Current

Leakage current refers to diodes conducting current when reverse-biased. Because of the narrower depletion region, Schottky diodes are more prone to high leakage current.

Lower Reverse Voltage

Similarly, the narrower depletion region makes Schottky diodes less tolerable to high reverse breakdown voltage. They have ~50V range while diodes with P-N junctions are able to tolerate 500V or more.

With how Schottky diodes are designed, they are also smaller and more compact compared to ordinary Si diodes. This is important, especially for applications where portability, space-saving, and integrability are crucial.

Applications of Schottky Diodes

Schottky diodes are ideal for applications focused on low forward voltage requirements, including the following:

Switch-mode power supplies (SMPs) - this diode is usually a rectifier in power supplies with high efficiency & DC-DC voltage converters. Schottky diodes make the SMPs more efficient and reduces heat loss. SMPs are commonly found in inverters.

Blocking diode - Schottky diodes are also used as a blocking diode in photovoltaic systems for their fast switching speeds, preventing battery discharge when produced voltage is less than battery voltage.

Voltage clamping - they are used to protect devices from reverse voltage & discharge by diverting unwanted electricity to the voltage rail, which is a line in electronics systems that can hold a certain amount of voltage and supply a small load to components without fluctuating the voltage too much. Voltage clamps with Schottky diodes are commonly used in Schottky transistors, integrated circuits, switching regulators, and digital circuits.

- Frequency mixer (also known as RF mixer) - Schottky diodes function as a frequency converter in RF mixers. Their faster switching speed and nonlinear voltage-current feature are ideal for handling the high frequencies encountered in RF applications. Schottky diodes convert the input radio frequencies to a desired intermediate frequency (IF) for further processing. RF mixers are commonly found in cell phones, radio receivers, transmitters, radar systems, spectrum analyzers and signal generators.

Design Challenges of Schottky Diodes

Aside from leakage current & lower reverse voltage, Schottky diode’s design also have the following challenges:

Thermal Runaway

Reverse leakages make Schottky diodes generate excessive heat that may potentially damage electronic devices. This is usually the case for high-power applications or when the diode is exposed to higher ambient temperatures.Electric Field Concentration

The interface between the metal and n-type semiconductor has sharp edges that generate localized electric fields that lead to breakdown and reverse leakage.Guard Ring Requirement

A p-type semiconductor connected to the circuit’s ground (a ground ring) is necessary to prevent breakdown around the sharp edges of the metal-semiconductor interface. Ground rings are the first component to break down during reverse leakage.CAPLINQ Solutions for Schottky Diodes

Designing Schottky diodes presents challenges primarily within the die, specifically at the metal-semiconductor junction. The key is to carefully select materials with properties that are highly compatible with the die's, ensuring optimal performance and reliability.

Like any other semiconductor devices, Schottky diodes are encapsulated in an epoxy molding compound. For maximum reliability, molding compounds with high adhesion, thermal stability, and CTE matching are required. LINQSOL EMC-G135 is highly recommended for Schottky diode encapsulation.

LINQSOL EMC-G135 is a green epoxy molding compound specifically developed for rectifier bridges (GBU, KBJ, GBS and etc.) and SMX packages. It offers good moldability and low modulus to meeting low-stress requirements. With a thermal conductivity of ~1.7W/m⋅K, it satisfies the heat dissipation required by high-performing packages. G135 boasts of its high-cost effectiveness and excellent workability with more than 500 continuous mold shots.

LINQSOL EMC-G135 guarantees strong performance and outstanding reliability. This product is deliberately formulated without the inclusion of substances prohibited by the European Union RoHS and REACH. LINQSOL EMC-G135 seamlessly integrates advanced material properties, safety compliance, and superior performance to deliver a reliable solution for semiconductor device encapsulation.

Selecting the right die attach material is also crucial in Schottky diode packaging. CAPLINQ provides a wide range of Die Attach Materials designed for various applications. Our selection includes high-conductivity epoxies, precision solders, and films. These materials ensure excellent thermal management and reliable electrical performance for your power devices, RF components, and microelectronics.microelectronics. Contact us for specialized technical support.

Frequently Asked Questions About Schottky Diodes

What’s commonly used as the n-type semiconductor in Schottky diodes?

N-type silicon semiconductors are commonly used in Schottky diodes but some applications also use Gallium Arsenide (GaAs) semiconductors. GaAs is typically used for higher frequency applications since its excellent electron mobility allows for faster switching speeds relative to its Si counterpart. It’s also used on devices that are exposed to radiation due to its insulating properties and ability to function at room temperature while exposed to extreme radiation.

What metals are typically used in Schottky diodes?

Aluminum, gold, tungsten, platinum, chromium or molybdenum are the commonly used metals in Schottky diodes that are connected to a n-type semiconductor. The potential difference in the Schottky barrier is highly dependent on the type of metal used since some metals may have a wider or narrower energy gap. This is the primary consideration when selecting which metal to use in these diodes.

Are diodes and switches the same?

Diodes and switches are not the same. Switches need to have an external stimulus to turn on and off. Switches allow current to flow in both directions while diodes function as a one-way valve; however, diodes can function as a switch because of forward and reverse bias.