Insulated-Gate Bipolar Transistor (IGBT)

In inverters, motor drives, renewable-energy converters, UPS, chargers, and welding equipment, an insulated-gate bipolar transistor (IGBT) is widely used to switch and control high voltage and high current efficiently in power-electronic systems.

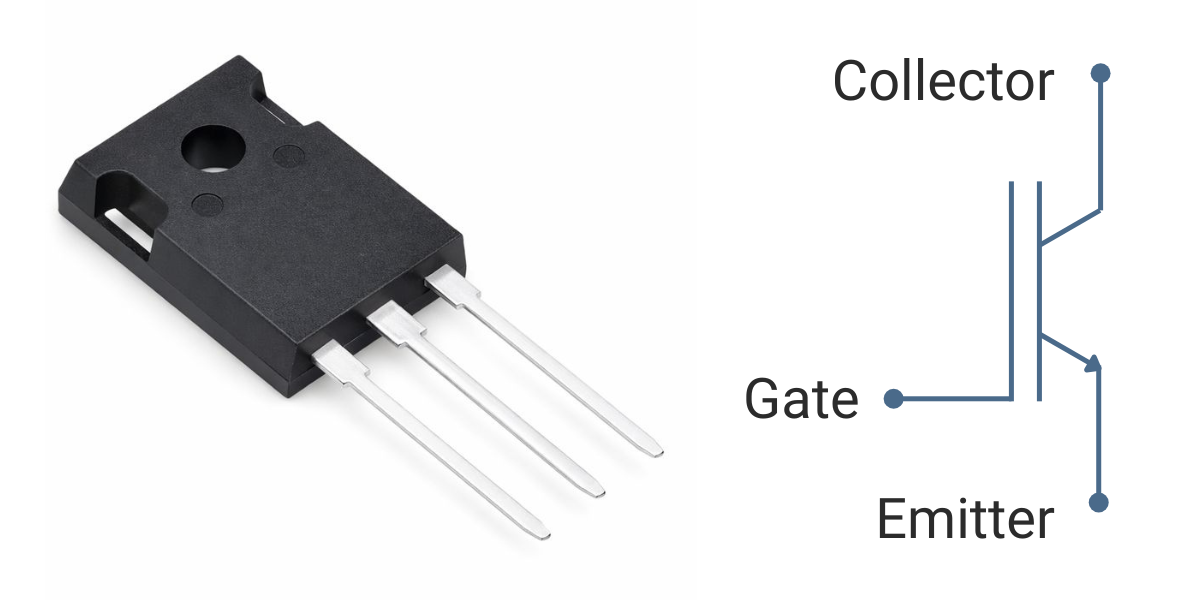

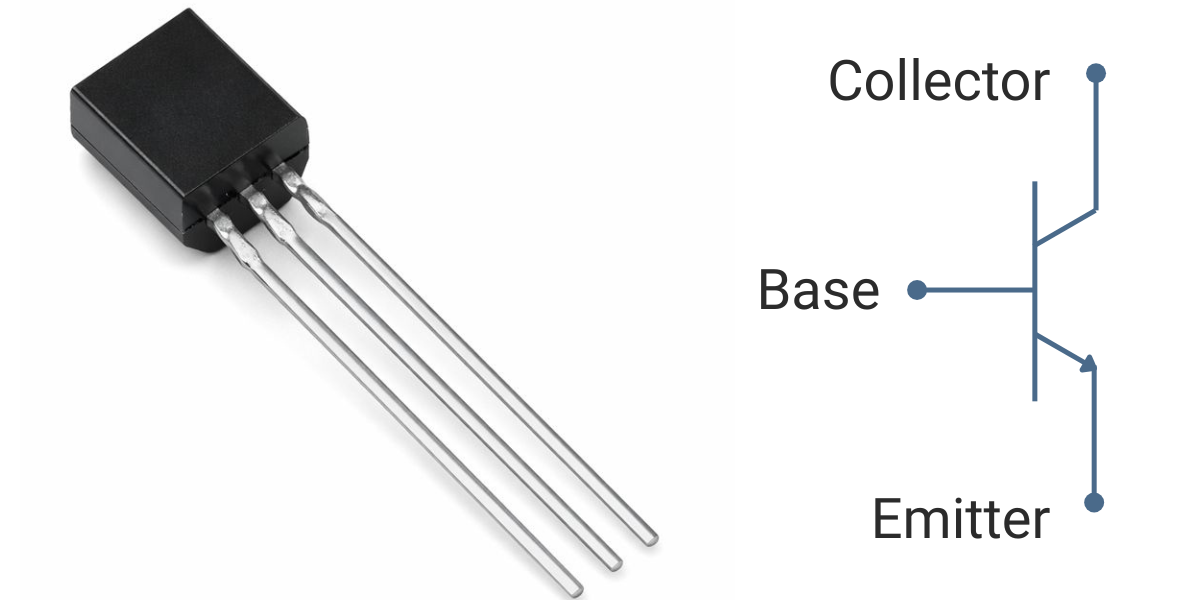

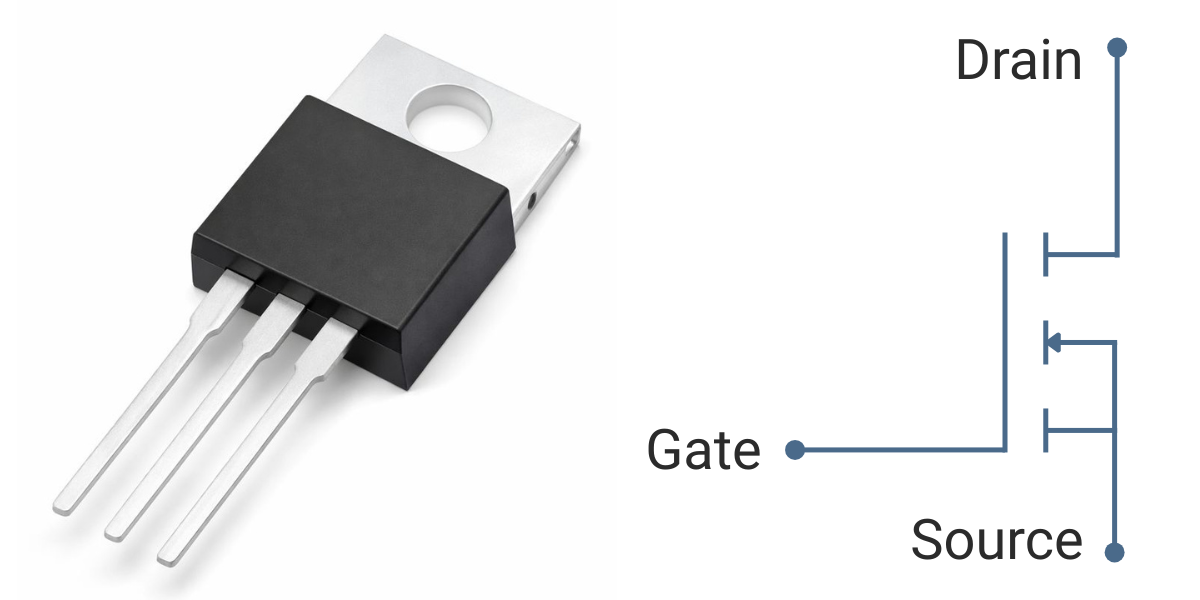

An IGBT is a high-power semiconductor device that combines the strengths of two proven technologies: the MOSFET, known for fast and precise switching, and the BJT, valued for low conduction loss at high current. This hybrid architecture enables efficient operation across a wide voltage range, typically from 600 V to 6.5 kV, making IGBTs well suited for high-power applications that require both efficiency and controllability.

IGBT vs MOSFET vs BJT Comparison

IGBT Package Types

Discrete IGBTs

Discrete IGBTs are single-device power switches used where high voltage, high current, and serviceability are required.

They are typically applied in the 600–1200 V range and are available in through-hole (TO-247, TO-220, TO-3P) and surface-mount formats.

The TO-247 package remains the industry workhorse, balancing conduction loss, switching speed, and thermal performance for 2–20 kHz operation.

High current capability, strong heatsink-mounted thermal path, and easy replacement during maintenance or field service.

Larger footprint and height, manual mounting, and higher lead inductance than SMT alternatives.

Motor drives, UPS/PFC stages, welding systems, chargers, and industrial inverters.

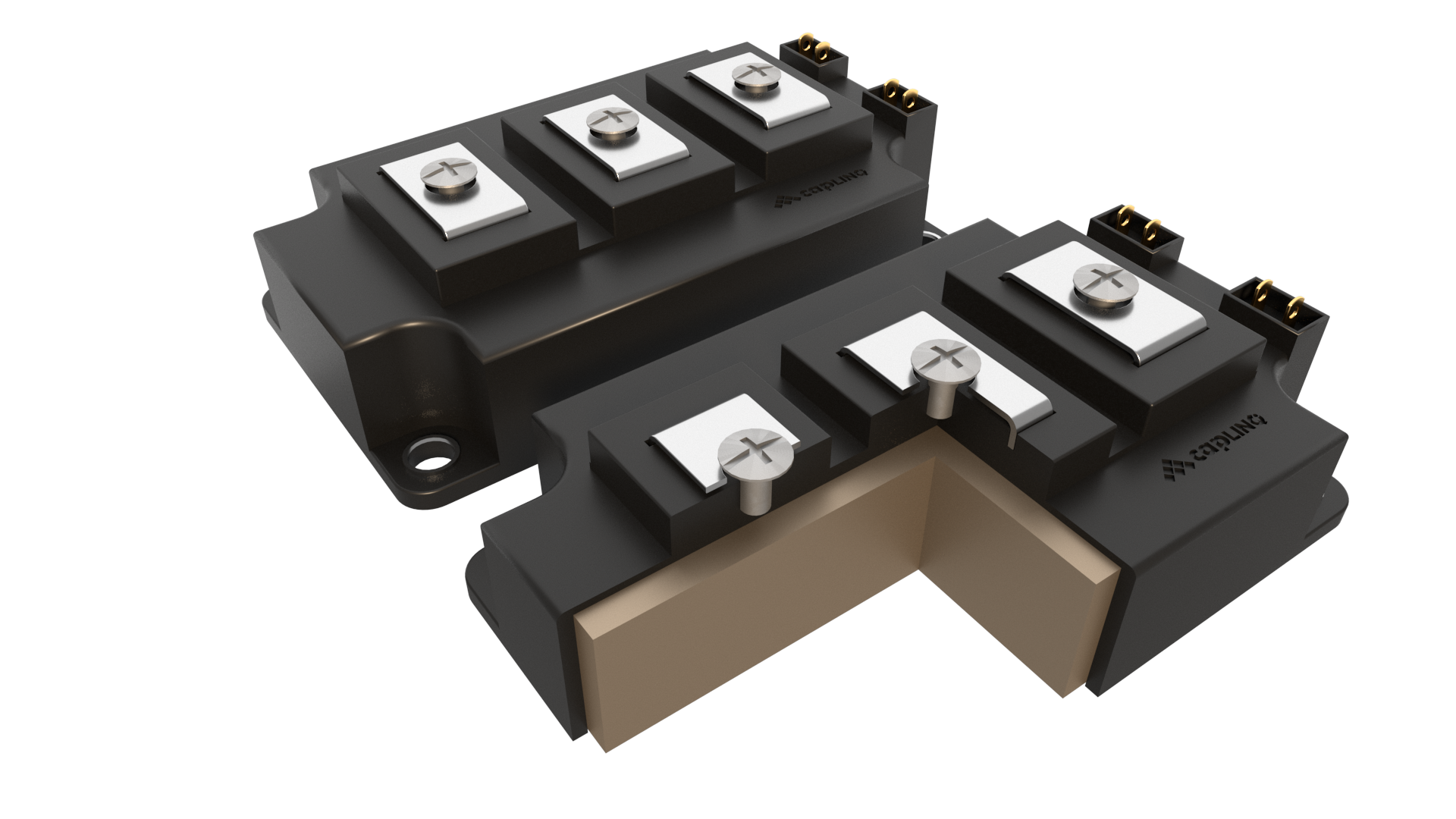

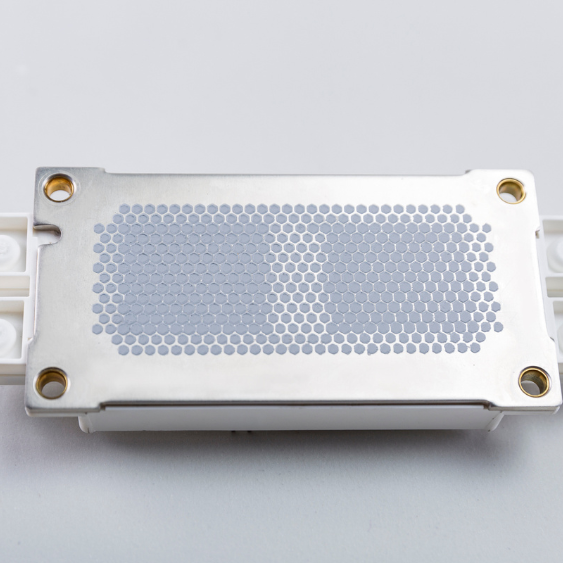

IGBT Modules

IGBT modules integrate multiple IGBT dies, freewheel diodes, and sensing elements into a single package to achieve high power density and simplified system integration.

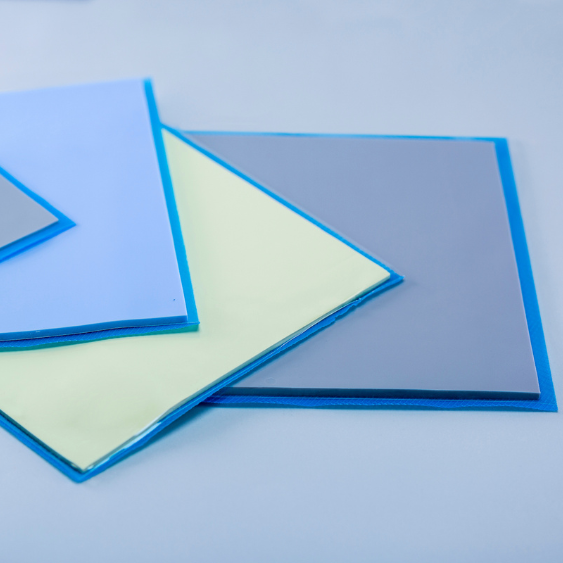

DBC substrates (Al₂O₃, AlN, Si₃N₄) provide electrical isolation and efficient heat spreading across common inverter topologies.

Baseplate, baseplate-less, transfer-molded, and double-sided cooling constructions address different thermal, mechanical, and lifetime requirements.

High power density, integrated freewheel diodes, reduced parasitics, and simplified electrical and mechanical assembly at high power levels.

Larger size and mass, higher unit cost, and less flexibility compared with discrete-device designs.

Industrial motor drives, PV and wind inverters, elevators, compressors, large UPS/PFC systems, and high-power traction or grid converters.

Where IGBTs Deliver the Most Value

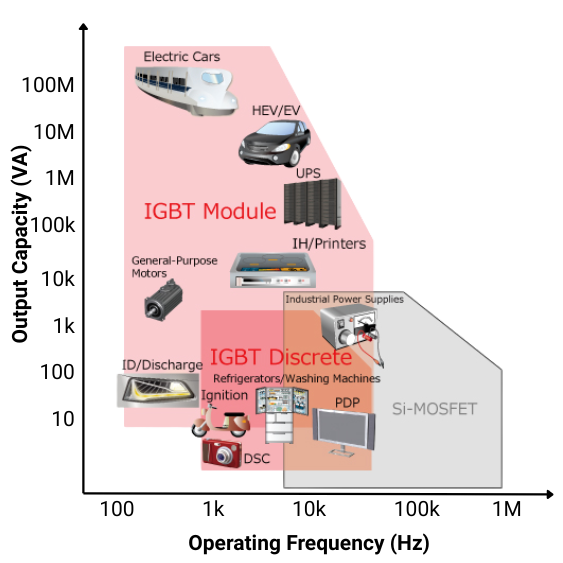

Silicon MOSFETs dominate high-frequency, lower-power designs, while IGBTs are optimized for medium switching frequencies (≈2–20 kHz) and high voltage/current operation. This makes IGBTs the preferred choice for motor drives, traction inverters, UPS systems, and industrial power conversion where efficiency and thermal stability matter more than ultra-fast switching.

Discrete IGBTs are typically used in lower- to mid-power equipment such as appliances and light industrial systems. As power levels increase, applications transition to IGBT modules, which integrate multiple dies, robust substrates, and optimized interconnects to handle high current, thermal cycling, short-circuit events, and long operating lifetimes.

IGBTs are purpose-built for high-power, medium-frequency applications where efficiency, ruggedness, and long-term reliability are critical. They occupy the operating space that defines modern industrial and automotive power systems.

Operating map showing where IGBT discretes, IGBT modules, and silicon MOSFETs are typically applied based on output capacity and switching frequency.

EV and HEV Traction Inverters

EV and HEV traction inverters typically operate with 400–800 V DC links and switching frequencies around 10–20 kHz. IGBTs are selected for their low VCE(sat) at high torque and predictable switching behavior at cruise and light-load conditions, helping minimize losses across real-world drive cycles.

Best-practice designs use Kelvin emitter packages, laminated DC links, tuned gate resistors, and fast freewheel diodes (often SiC). Combined with durable thermal paths, such as sintered silver die attach, Si₃N₄ DBC substrates, and high-performance TIMs, IGBT modules deliver high power-cycling endurance and stable efficiency over vehicle lifetimes.

Solar and Wind Power Conversion

In PV and wind power systems, IGBTs form the backbone of DC/AC inverters and DC/DC stages, particularly at 1.0–1.5 kV system voltages. Multilevel topologies such as NPC and T-type reduce device stress and switching losses, enabling higher efficiency at moderate switching frequencies.

Wind turbine converters may use press-pack IGBTs for line-side robustness, while PV string and central inverters commonly adopt IGBT modules paired with SiC diodes to optimize efficiency, grid-code compliance, and lifecycle cost.

Drives, Equipment, and Welding

Variable-frequency drives for pumps, compressors, conveyors, and robotics typically switch in the 2–8 kHz range, where IGBTs offer excellent conduction efficiency, thermal robustness, and a wide safe operating area.

Welding power sources, characterized by long cables and severe load transients, favor fast IGBT variants with carefully tuned gate networks and tailored snubbers to control dv/dt and overshoot, enabling stable arcs and long service life.

UPS Systems and High-Power Charging

Double-conversion UPS systems used in data centers, hospitals, and industrial facilities rely on IGBT bridges for high-efficiency inversion, fast transfer, and clean output waveforms under high crest-factor loads.

Front-end PFC stages and high-power DC chargers similarly depend on IGBTs for heavy RMS current handling and robust protection schemes, often combining IGBT power stages with SiC diodes to reduce switching losses while preserving favorable conduction performance at scale.

Key Challenges in IGBT Packaging

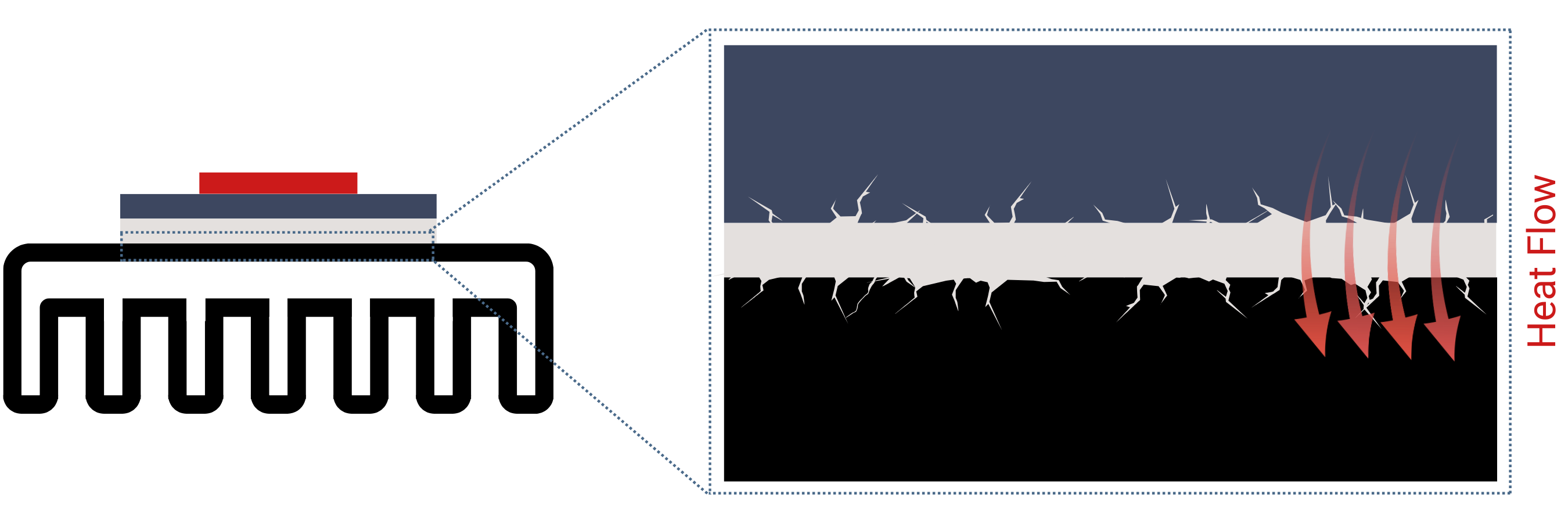

During conduction and switching, a portion of electrical energy is inevitably converted into heat. Effective IGBT packaging relies on high-thermal-conductivity bonding and encapsulation materials with thin, uniform bond layers to move heat efficiently from the die to the substrate and cooling system, minimizing junction temperature rise and thermal fatigue.

Impurities, residual solvents, and trapped air pockets can create localized weak points that promote leakage current, partial discharge, or arcing at high voltage. Reliable designs use low-impurity, solvent-free materials that cure cleanly, bond tightly, and support low-void assembly to maintain stable electrical insulation over long service life.

Differences in thermal expansion between silicon, substrates, die attach, and encapsulants introduce mechanical stress during thermal cycling. Selecting conductive die-attach and encapsulation materials with appropriate stiffness, along with controlled bond-line thickness, helps balance heat transfer while reducing cracking, delamination, and warpage.

Automotive, aerospace, and industrial duty cycles demand stable operation at elevated temperatures (typically 175–220 °C), along with resistance to moisture, vibration, and long service life. This drives the use of automotive-grade materials, high-temperature molding compounds, silicone gels, advanced ceramic substrates, and durable thermal interface materials, validated through extended heat and power-cycling tests.

CAPLINQ Solutions for IGBT Packaging

Reliability is largely a materials-and-packaging achievement. IGBT packages must deliver strong heat flow, clean insulation, and mechanical durability to survive automotive and industrial duty. Core requirements include: low thermal resistance; steady performance at high temperature (≈175–220 °C); resistance to moisture, vibration, and long power/thermal cycling; low voids; low-ionic/clean chemistry; good adhesion; corrosion resistance; adequate creepage/clearance; manufacturability and inspection readiness.

Thermal Interface Materials for IGBT Packaging

Effective IGBT thermal performance starts at the package-to-heatsink interface. Before addressing internal package materials such as die attach and encapsulation, engineers must first control interface thermal resistance, bondline thickness, and long-term stability under real clamp force and thermal cycling conditions.

In both discrete IGBTs and power modules, the thermal interface material (TIM) bridges microscopic air gaps between the IGBT baseplate or tab and the heatsink or cold plate. Because air is a poor thermal conductor, even small interfacial voids can dominate the junction-to-case thermal path and directly limit usable power density.

The thermal interface layer governs heat transfer from the IGBT package into the cooling system.

Why TIMs Matter in IGBT Applications

- Lower interfacial thermal resistance: Thin, uniform bondlines reduce contact resistance.

- Stable cycling performance: Resists pump-out, dry-out, and fatigue.

- Extended package lifetime: Lower Tj reduces thermo-mechanical stress.

- Reduced cooling demand: Improves heatsink and system efficiency.

- Higher system efficiency: Lowers auxiliary fan and pump power.

Thermal Interface Material Forms

With interface thermal performance defined as a priority, attention turns to TIM form selection. Thermal interface materials are available in several formats, each offering trade-offs in bondline thickness control, application method, cycling stability, and compatibility with IGBT package geometries.

Phase Change Materials

Enable thin, uniform bondlines with stable thermal performance and minimal pump-out.

Thermal Putty Pads

Highly conformable materials designed to accommodate large tolerances and surface flatness variation.

Thermal One-Part Hybrids

Dispense-ready materials supporting high throughput, long-term reliability, and reworkability.

Thermal Gap Pads

Compressible pads that provide electrical insulation and stress relief across uneven interfaces.

Thermal Grease

Easy-to-apply materials offering good initial performance but requiring pump-out validation.

Thermal Two-Part Hybrids

Dispensed systems combining softness, reliability, and long service life.

Why Phase Change Materials Are Ideal for IGBT Applications

Among available TIM formats, phase change materials (PCMs) are widely regarded as the most suitable thermal interface for IGBT packages. They combine low and stable thermal resistance, controlled bondline thickness, and high-volume manufacturing compatibility under realistic clamp force and thermal cycling conditions.

Thermal Performance

- Melts at operating temperature to wet surface asperities

- Forms thin, uniform bondlines under clamp pressure

- Minimizes interface thermal resistance (Rth)

Long-Term Stability

- Resists pump-out during power and temperature cycling

- Maintains consistent thermal performance over life

- Reduces risk of dry-out compared to greases

Manufacturability

- Available as pads, films, and dispensable pastes

- Paste formats support automated printing, including common honeycomb patterns

- Enables controlled material distribution and predictable bondline thickness

- No cure step or mixing required

For IGBT baseplates and module footprints where clamp force, surface flatness, and thermal cycling dominate interface behavior, PCMs provide a predictable and repeatable thermal solution aligned with both performance targets and manufacturing constraints.

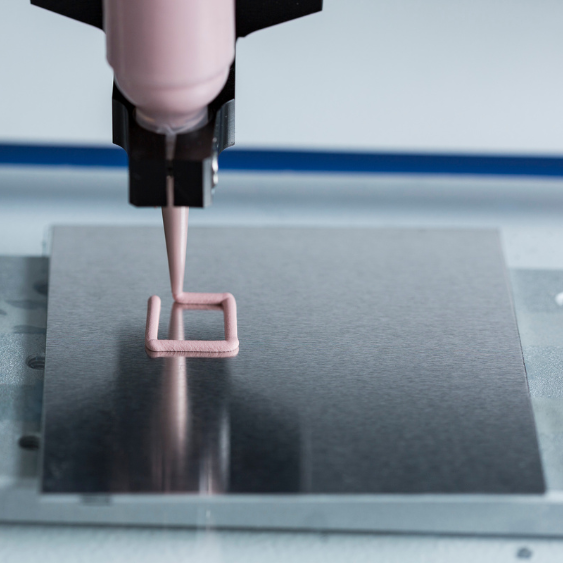

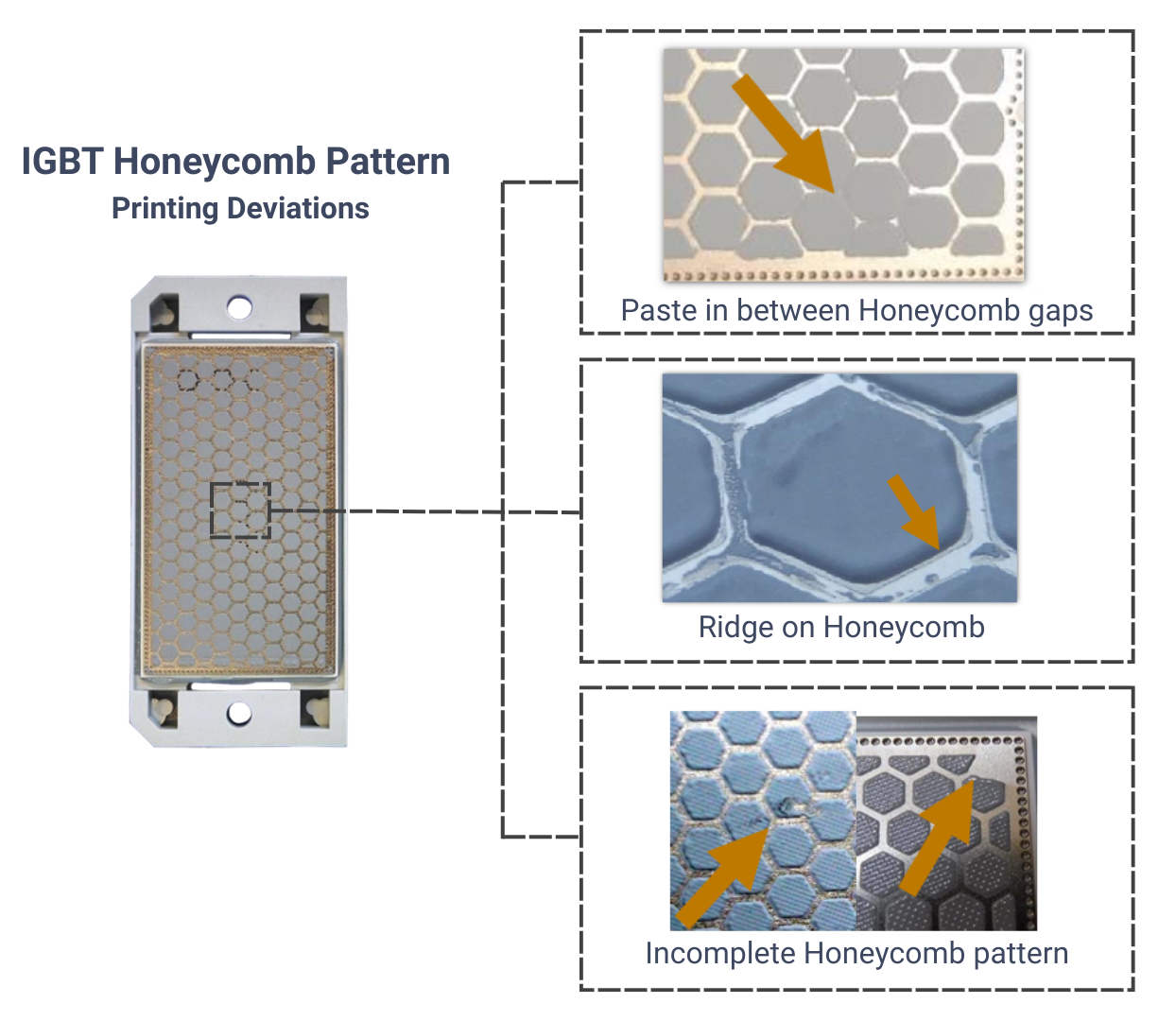

Honeycomb Pattern Printing on IGBT Modules

Honeycomb pattern printing is a common thermal interface material (TIM) dispensing technique for IGBT modules, where paste-based TIMs are deposited in a hexagonal mesh pattern across the module baseplate. This geometry enables controlled material placement, promotes uniform compression during mounting, and supports predictable bondline thickness (BLT).

Practical Challenges in Honeycomb Printing

Stencil Complexity & Wear

Fine hexagonal apertures require precision stencil fabrication and may wear faster.

Incomplete Fill or Missing Cells

High viscosity or suboptimal release can lead to missing hexagons.

Alignment Sensitivity

Stencil misalignment distorts material distribution.

Process Uniformity on Large Modules

Maintaining consistent pressure becomes increasingly challenging.

TIM Rheology Dependency

Not all paste-based TIMs release cleanly.

Pattern Deformation During Compression

Uneven clamp force can cause BLT variation.

Additional Setup and Inspection

More frequent cleaning and inspection are required.

Because honeycomb printing performance is highly sensitive to TIM rheology, stencil release behavior, and stability under clamp force, material selection becomes a critical design variable for IGBT modules. Phase change materials formulated specifically for paste printing can help mitigate many of the process and reliability challenges described above.

PTM6000HV

PTM6000HV is a paste-format phase change material (PCM) engineered to minimize interfacial thermal resistance while maintaining stable performance under long-term thermal and power cycling conditions typical of IGBT operation. Its polymer-based PCM structure enables excellent wetting at operating temperature, resulting in low surface contact resistance and predictable thermal performance.

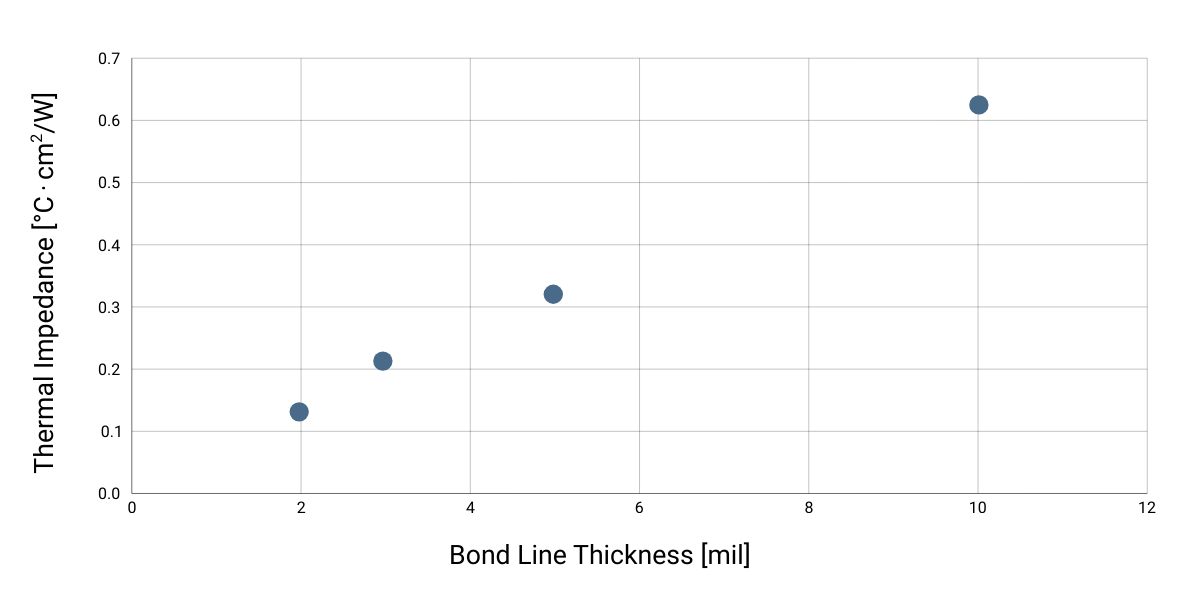

Engineering takeaway: PTM6000HV-SP maintains low and stable thermal impedance across practical bondline thickness ranges used in IGBT modules, while its high-viscosity paste formulation supports reliable honeycomb stencil printing and repeatable interface performance.

Thermal Impedance vs. Bondline Thickness

Typical thermal impedance values measured under controlled test conditions.

Key Material Properties

5.2 W/m·K

0.09 °C·cm²/W

0.14 °C·cm²/W

200–466 Pa·s (high-viscosity paste)

Volume resistivity: 2.1 × 10¹⁴ Ω·cm

Typical property values shown for reference only and should not be used as specifications.

Processing & Handling Guidance for PTM6000HV

The following references provide practical guidance on process setup, handling behavior, and application constraints when using PTM6000HV for honeycomb-pattern dispensing on IGBT modules.

Drying Time & Handling Characteristics

Provides reference data on drying time, process windows, and handling behavior relevant to stencil printing, inspection, and pre-assembly dwell time prior to module clamping.

Manual Honeycomb Pattern Printing Demonstration

Demonstrates manual stencil printing of PTM6000HV-SP in a honeycomb pattern, highlighting paste release behavior, pattern definition, and visual quality prior to compression.

Alternative Phase Change Materials for IGBT Applications

Depending on thermal loading, interface pressure, and long-term reliability requirements, the following phase change materials may be considered as alternatives to PTM6000HV-SP.

PTM7950 [Go to PTM7950 Product Page↗]

- Ultra-high thermal conductivity (~8.5 W/m·K)

- Very low thermal impedance (~0.04 °C·cm²/W)

- Forms extremely thin bondlines under clamp pressure

- Available in pad and printable paste formats

- Stable performance in vertical and high-power orientations

Best suited for: IGBT modules where maximum heat flux removal and minimum interface resistance are the primary design drivers.

PTM6880 [Go to PTM6880 Product Page↗]

- Engineered to eliminate pump-out during thermal cycling

- Maintains consistent interface behavior over service life

- Enhanced resistance to material migration and flow

- Designed for variable clamp force and dynamic loading

- Supports stable thermal impedance over time

Best suited for: IGBT applications where long-term reliability and interface stability outweigh peak thermal conductivity.

Final material selection should consider interface pressure, surface flatness, thermal cycling severity, and manufacturing constraints. Application-specific validation is recommended.

Die Attach Materials for IGBT Packages

Die attach creates the thermal, electrical, and mechanical connection between the silicon die and the substrate. In IGBT packages, this interface must support high junction temperatures (~175–250 °C), low voiding, and stable performance under repeated power and thermal cycling typical of automotive and industrial operation.

Today, solder-based systems and conductive epoxies remain common, particularly in discrete devices, while silver sintering has become a mainstream solution in high-power IGBT modules due to its superior thermal and cycling performance.

Solder-Based Die Attach

- Mature, high-throughput manufacturing with established reflow processes

- Good electrical and thermal conductivity when microstructure is controlled

- Broad alloy options (SnAg, AuSn, high-lead systems)

Limitations: creep-fatigue, void control, flux residues, lower thermal conductivity vs. Ag-sinter, re-melt risk, and RoHS constraints.

Silver Sintering Die Attach

- Very high thermal conductivity and ultra-low thermal resistance

- Excellent high-temperature and power-cycling robustness

- Strong mechanical and electrical integrity with low voiding

Limitations: higher material and tooling cost, surface finish requirements (Ag/Au), tighter process control, and limited reworkability.

Recommended Die Attach for IGBT Packaging

- Low thermal resistance with stability at elevated junction temperatures

- Clean, low-void bonds validated through inspection and qualification

- Compatibility with DBC and leadframe finishes (Au, Ag, Cu)

For both discrete IGBTs and power modules, materials must deliver low thermal resistance and stable high-temperature performance (≈175–250 °C), clean, low-void, well-adhered bonds, and finish/process compatibility with common DBC and leadframe surfaces (Au/Ag/Cu).

Solder-based Die Attach

ALPHA® High-Lead Die-Attach Solder Preforms ↗

4N-purity PbSn/PbSnAg/PbSb preforms in die-attach shapes (discs/squares), hermetically packed; supports high-temperature, forming-gas reflow for low-void, robust joints in IGBT discretes and modules.

- High-temperature stability & strong heat conduction

- Compatible with Au/Ag/Cu finishes; wide size range

LINQALLOY SP-PSA525 (92.5Pb/2.5Ag/5Sn) ↗

High-lead no-clean solder paste engineered for die-attach dispensing; consistent deposits, strong joints, and good wetting for power-semiconductor assembly.

- Built for automated dispensing; low voiding

- Minimal, non-conductive residues

Silver-Filled Epoxy Die Attach

LOCTITE® ABLESTIK 84-1LMISR4 ↗

Silver-filled epoxy die-attach adhesive for high-throughput lines; heat-cure system widely adopted in power electronics.

- Clean dispensing; strong adhesion

- Stamping, stencil, or dispensing compatible

LINQBOND™ DA-8030 ↗

Single-component, silver-filled die-attach adhesive with high thermal and electrical conductivity.

- Low-temperature cure option

- Low voiding; strong adhesion

Silver Sintering Die Attach

LOCTITE® ABLESTIK SSP 2020 ↗

Silver sintering paste for high-heat-transfer power devices; maintains adhesion up to ~260 °C.

- Ultra-low thermal resistance

- Thermal conductivity up to ~200 W/mK

LINQBOND™ DA-8060S (Pressure-less Silver Sinter) ↗

Pressure-less silver-sinter die-attach with high thermal conductivity and strong adhesion.

- Low-void bonds for IGBT modules

- Optimized thermal and electrical paths

Encapsulation for IGBT Packaging

Encapsulation in discrete IGBTs and power modules is a critical packaging step that provides environmental protection and long-term reliability. By sealing the die and interconnects, encapsulation prevents moisture, gas, and contaminant ingress, helping maintain stable electrical and mechanical performance under harsh industrial and automotive operating conditions.

Encapsulation around die and interconnects to resist moisture, shock, and thermal cycling.

Why encapsulation matters

- Shields against environment: Encapsulation blocks moisture, dust, and chemicals, preventing corrosion and extending IGBT life.

- Strengthens & stabilizes: It absorbs stress from heat cycling and vibration, keeping chips, wires, and components secure and reliable.

- Insulates & cools: Encapsulation provides high-voltage insulation, manages electric fields, and helps transfer heat for safe operation.

Encapsulation for IGBTs is chosen by balancing electrical insulation, thermal stability, mechanical stress relief, environmental resistance, and process fit. Silicone gels suit high-voltage/PD resistance, epoxies give rigidity and high Tg, while filled systems improve heat spreading for demanding EV and industrial modules.

High Tg EMC for IGBT

LINQSOL™ EMC-7535MF ↗

High-Tg, low-stress, halogen-free EMC for high-voltage / high-power discrete packages (e.g., TO-220, TO-247) and IGBT modules.

- Tg: 215 °C | CTI: 600 V | UL94: V-0

- Low moisture absorption; low ion content

HYSOL GR750 ↗

Halogen-free, silica-filled EMC with very high Tg for robust power packages and wide-bandgap devices.

- Tg: 235 °C | Low moisture absorption

- Excellent adhesion to Ni-plated leadframes

LINQSOL™ EMC-G374 ↗

Ultra-high-Tg EMC for high-power SiC / GaN and IGBT packages where temperature stability is critical.

- Ultra-high Tg class

- Engineered for demanding encapsulation

Thermally Conductive EMC for IGBT

LINQSOL™ EMC-G375 ↗

High-thermal-conductivity EMC for full-pack TO power packages and high-power rectifier packages.

- Thermal conductivity: up to ~3.3 W/m·K

- Built for heat dissipation and long-term reliability

LINQSOL™ EMC-5013 ↗

Thermally conductive EMC for TO-220F, TO-3PF and full-pack power packages.

- >2 W/m·K | UL94 V-0

- Low water absorption

Dielectric Silicone Gels for IGBT

LINQBOND™ PM-4911HV ↗

Two-part, low-stress silicone gel for IGBT modules and discrete power devices. Mixes 1:1 and cures to a soft, clear gel that insulates, seals and damps vibration for long-life operation.

- Low modulus; vibration damping

- Moisture & dielectric protection

- Potting/gel filling for IGBT modules & TO-packages

DOWSIL™ EG-4175 ↗

High-temperature dielectric silicone gel for next-gen IGBT modules. Self-priming adhesion and self-healing behavior help protect against thermal and mechanical stress.

- Up to ~180 °C operation

- EV traction, PV/wind inverters, industrial power

- Room-temperature cure; heat-accelerated optional

Elantas Bectron® SG-75V1-15 ↗

Two-part silicone gel that cures at room temperature to a very soft, transparent encapsulant. Wide service range and excellent dielectric insulation for power electronics.

- RT cure (~24 h); heat-accelerated optional

- -45 °C to +200 °C

- Potting IGBT modules & sensitive power assemblies

Thermally Conductive Silicone Gels for IGBT

LINQBOND™ PM-Si611 ↗

Two-part, thermally conductive silicone potting material for IGBT discretes and modules; designed for heat dissipation, electrical insulation, and reliable gel-like stress relief.

- >1.0 W/m·K | UL94 V-0

- Fast cure options

DOW SYLGARD™ 170 ↗

Two-part silicone encapsulant/gel with moderate thermal conductivity and good flow for potting power electronics; suitable for heat-spreading and dielectric protection around IGBT assemblies.

- ~0.4 W/m·K

- Dielectric protection for power electronics

Further Reading on Power Electronics Materials

Optimize performance and long-term reliability in IGBT and power module designs.

Talk to our engineers about selecting the right materials based on your package design, thermal requirements, and operating conditions.