PIT1S-ESD-DCD | 1 mil Die Cut ESD Polyimide (Kapton) Tape with Silicone Adhesive | Single side Discs

- 1 mil polyimide film

- Single side Silicone adhesive

- >6500V breakdown voltage

Product Description

CAPLINQ LINQTAPE™ PIT1S-ESD Series polyimide tape is a high-temperature resistant, antistatic treated polyimide film mounted with a silicone adhesive. It is designed for both masking and temporary bonding in many high-temperature applications in semiconductor, electronic, automotive, and other general manufacturing industries.

LINQTAPE™ PIT1S-ESD Series polyimide tape provides an excellent balance of electrical, mechanical, thermal, and chemical properties over a wide range of temperatures. It has enhanced strength for puncture and tear resistance and can be used in applications that may see intermittent temperatures up to 260°C (500°F).

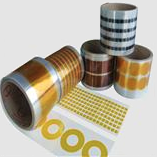

LINQTAPE™ PIT1S-ESD-DCD tapes come in varying designs and patterns. This tape can be delivered in a range of die-cut disc sizes with diameters ranging from 1/8" to 12". Custom thicknesses, designs, and diameters are available upon request.

Key Features

- Low peel voltage

- Anti-static conductive polymer

- Excellent dielectric properties

Technical Specifications

| General Properties | |||||

| Adhesive Layer Adhesive Layer A layer that is applied to one surface or both to bind items together and resist their separation | Silicone | ||||

| Adhesive Thickness Adhesive Thickness Adhesive thickness indicates the thickness of an adhesive layer. It refers to the adhesive thickness of a single side so for double sided tapes it always needs to be multiplied. | 38.1 µm | ||||

| Chemistry Type | Polyimide | ||||

| Color Color The color | Amber | ||||

| Film Thickness Film Thickness Film thickness is the thickness of a backing film without taking into account any coatings or adhesive layers. It is measured in micron and the conversion factor to mil is 0.039. | 25.4 µm | ||||

| Release Liner Release Liner A paper or plastic-based film sheet used to prevent a sticky surface from prematurely adhering | None | ||||

| Single or Double-Sided Adhesive Single or Double-Sided Adhesive Describes whether a tape is single- or double-sided. If it is single-sided, it has adhesive only on one side of the backing film. If it is double-sided, then it has adhesive on both sides of the backing film. | Single-Sided | ||||

| Special Layer | Antistatic Polymer Coating | ||||

| Total Thickness Total Thickness Total thickness is taking into account all the films, coatings, adhesives, release liners and special layers and is the maximum thickness of a film or tape. | 63.5 μm | ||||

| Mechanical Properties | |||||

| Adhesion Strength Adhesion Strength Adhesion is the bond strength measurement of a coating to a substrate. When an adhesive is bonded to an item or surface, numerous physical, mechanical and chemical forces come into play, which may have an effect on each other. | 19 Oz/in | ||||

| Elongation Elongation Elongation is the process of lengthening something. It is a percentage that measures the initial, unstressed, length compared to the length of the material right before it breaks. It is commonly referred to as Ultimate Elongation or Tensile Elongation at break. | 55 % | ||||

| Electrical Properties | |||||

| Breakdown Voltage Breakdown Voltage Breakdown voltage is the minimum voltage necessary to force an insulator to conduct some amount of electricity. It is the point at which a material ceases to be an insulator and becomes a resistor that conducts electricity at some proportion of the total current. After dielectric breakdown, the material may or may not behave as an insulator any more because of the molecular structure alteration. The current flow tend to create a localised puncture that totally alters the dielectric properties of the material. This electrical property is thickness dependent and is the maximum amount of voltage that a dielectric material can withstand before breaking down. The breakdown voltage is calculated by multiplying the dielectric strength of the material times the thickness of the film. | >6500 V | ||||

| Dielectric Strength Dielectric Strength Dielectric strength is measured in kV per mm and is calculated by the Breakdown voltage divided by the thickness of the tested material. Those two properties go hand in hand and while Breakdown voltage is always thickness dependent, dielectric strength is a general material property. As an example, the dielectric strength of Polyimide is 236 kV/mm. If we place 1mm of Polyimide between two electrodes, it will act as an insulator until the voltage between the electrodes reaches 236 kV. At this point it will start acting as a good conductor, causing sparks, potential punctures and current flow. | 256 kV/mm | ||||

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 1.0x1013 Ohms⋅cm | ||||

| |||||

| |||||

| Thermal Properties | |||||

| Temperature Resistance Temperature Resistance Temperature resistance is the maximum temperature that the material or product can withstand for a period of time. The temperatures listed should be considered as guidelines for an operating temperature of about 30 minutes. Typically, the material can withstand much longer times at temperatures about 20°C lower and can withstand much higher temperatures for short, intermittent times. | 260 ˚C | ||||

| Other Properties | |||||

| RoHS Compliant RoHS Compliant RoHS is a product level compliance based on a European Union Directive which restricts the Use of certain Hazardous Substances in Electrical and Electronic Equipment (RoHS). Products compliant with this directive do not exceed the allowable amounts of the following restricted materials: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), with some limited exemptions | Yes | ||||

| VOC-Free (100% solids content) VOC-Free (100% solids content) VOC means Volatile Organic compound. VOCs are evaporating molecules and are literally everywhere around us. Our scents are volatile organic compounds, most of the things that we smell are VOC etc. So what do we mean when we state that a product is VOC free? A VOC free product, according to the FTC is one where: 1)VOCs have not been intentionally added to the product. 2)The presence of VOCs at that level does not cause material harm that consumers typically associate with VOCs, including but not limited to, harm to the environment or human health. 3)The presence of VOCs at that level does not result in concentrations higher than would be found at background levels in the ambient air. | Yes | ||||

Additional Information

Product Applications

In sheet form (LINQTAPE PIT1S-ESD Series), the antistatic tapes are used to safely dissipate electrostatic charges before they can build up and cause harmful ESD events to critical electronic components.

These antistatic tapes also have a high dielectric strength which allows them to be used as electrical insulators and isolators. Further to this, these antistatic polyimide tapes have a low peel voltage feature which is important as they generate little voltage when they are unrolled – thereby protecting static-sensitive devices by minimizing the electrostatic charges added when the tape is applied.

This combination of properties makes them suitable for a range of applications including but not limited to batteries, smartphones, tablets, and any other application that requires an anti-static polyimide tape.

In disc form (LINQTAPE PIT1S-ESD-DCD Series), the precut shapes can be peeled right on the release liner and applied. CAPLINQ can also make custom-made stamped polyimide shapes that are stamped according to your specifications. Ask your representative for more information.

The silicone adhesive used makes it better suited to even higher temperature applications, but in the case that a silicone adhesive cannot be used, CAPLINQ offers also a version with an acrylic adhesive, PIT1A-ESD Series.

Application Ideas

- Protection of static-sensitive devices

- Temporary bonding of thermocouples for oven profiling

- Bonding of devices before solder reflow

- Splicing of Insulation Layers

- Gold Finger Masking

- Insulating circuit boards and coils