eMobility

WHAT EMOBILITY IS AND WHY IT MATTERS

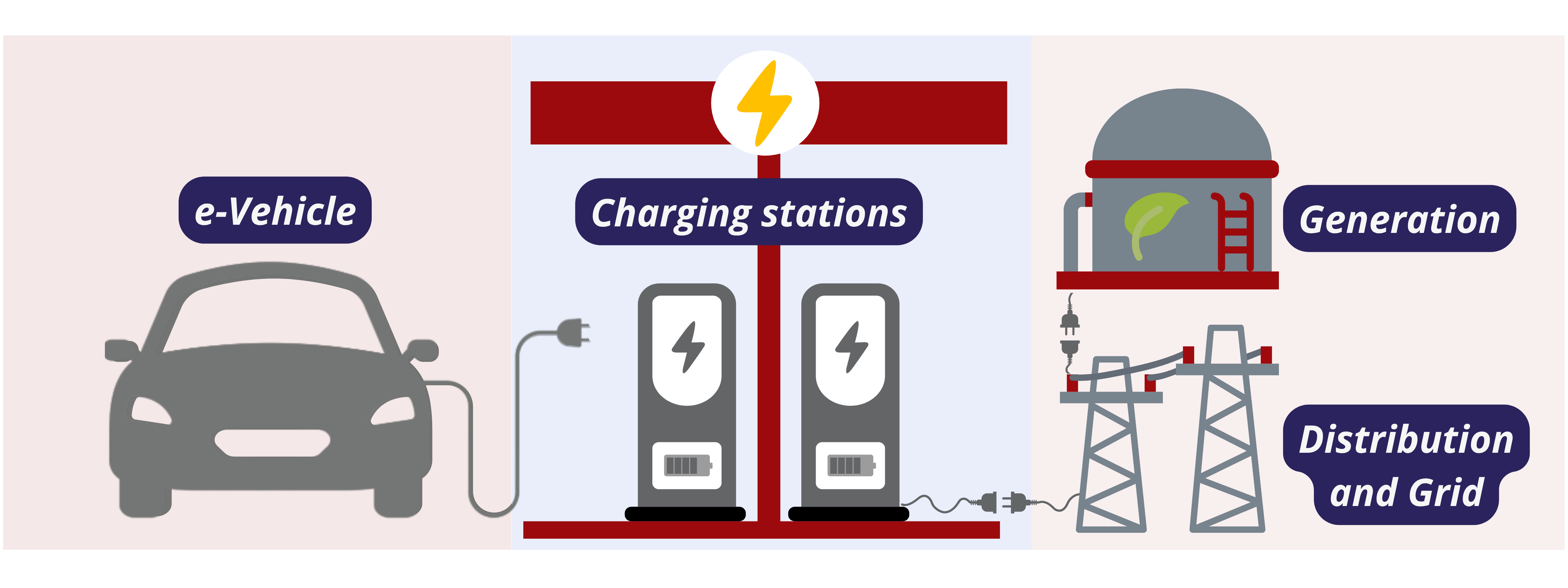

eMobility, or electric mobility, refers to the use of electric-powered vehicles and the infrastructure that supports them. This spans everything from electric cars, buses, and bikes to charging networks, battery energy storage systems (BESS), and smart electric grids. It also connects with renewable energy and advanced materials. Simply put, eMobility is reshaping both transportation and energy as part of a broader push toward a greener future.

“E-mobility is all about the interconnectivity, electricity generation, distribution, charging, and storage opportunities it brings.”

eMobility is more than just a trend . . . It is an interdisciplinary and central strategy for achieving global climate goals while still enabling smarter transportation systems, and the rest of the world is aware of it. Global EV sales surged by 24% year-over-year to 1.8 million in just June 2025. This is driven by economic incentives and falling vehicle costs in countries like China and Europe. Meanwhile, cities are aggressively rolling out policies for charging station installations and renewable energy options. This serves as a statement to the growing consumer momentum worldwide in support of zero-emission targets and decarbonization efforts.

This transition is reshaping not only how we move but also how we generate, distribute, and even store energy. Apart from needing more batteries and motors, this shift requires a new class of high-performance materials and chemistries that meet the demands of electrical, thermal, mechanical, and environmental extremes.

TYPES AND PARTS OF ELECTRIC VEHICLES

What powers the difference lies within the EV itself.

Traditional vehicles powered by internal combustion engines (ICEs) rely on burning fuel, usually gasoline or diesel, to generate mechanical power. This process involves key automotive components, such as the engine, fuel tank, fuel pump, and exhaust system. While this has been an effective means of transportation, ICE vehicles emit significant greenhouse gases, such as carbon dioxide and methane, as well as harmful pollutants like carbon monoxide and volatile organic compounds, all of which substantially contribute to air pollution and climate change.

Electric vehicles (EVs), on the other hand, use electricity stored in a battery to power the vehicle, eliminating the combustion process and effectively removing the gas emissions. Instead of relying solely on engines and tanks, EVs rely on a carefully coordinated system of electronic components that work together seamlessly.

Because drivers have diverse needs, EVs come in different types designed to balance electric power and fuel efficiency.

Generally, there are 3 main types of Electric Vehicles that allow drivers to select the EV best suited for their lifestyle:

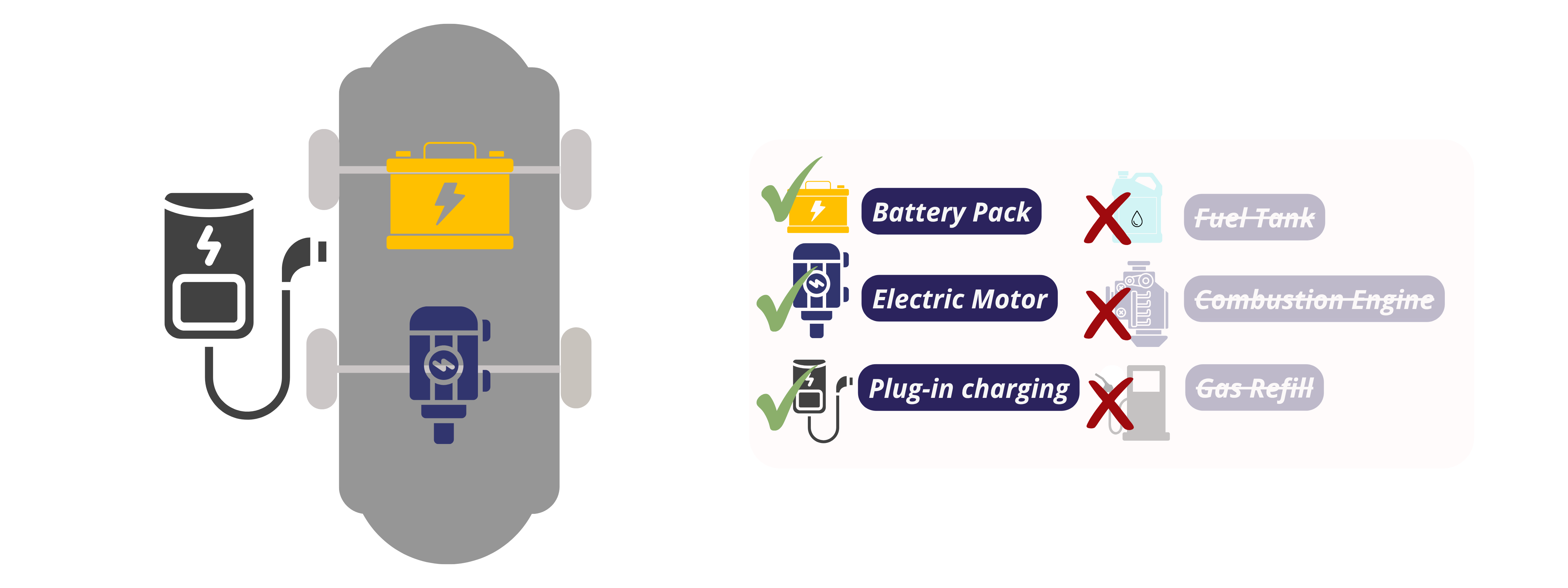

Battery Electric Vehicles (BEVs)

BEVs are fully electric vehicles that rely exclusively on electricity stored in rechargeable lithium-ion battery packs. They can only be recharged by plugging into an external power source. This type produces zero tailpipe emissions.

✅ Pros: Zero tailpipe emissions, Lower operating and maintenance costs, Quiet and smooth operation

❌ Cons: Limited range compared to ICE vehicles, Long charging times, Dependent on charging infrastructure

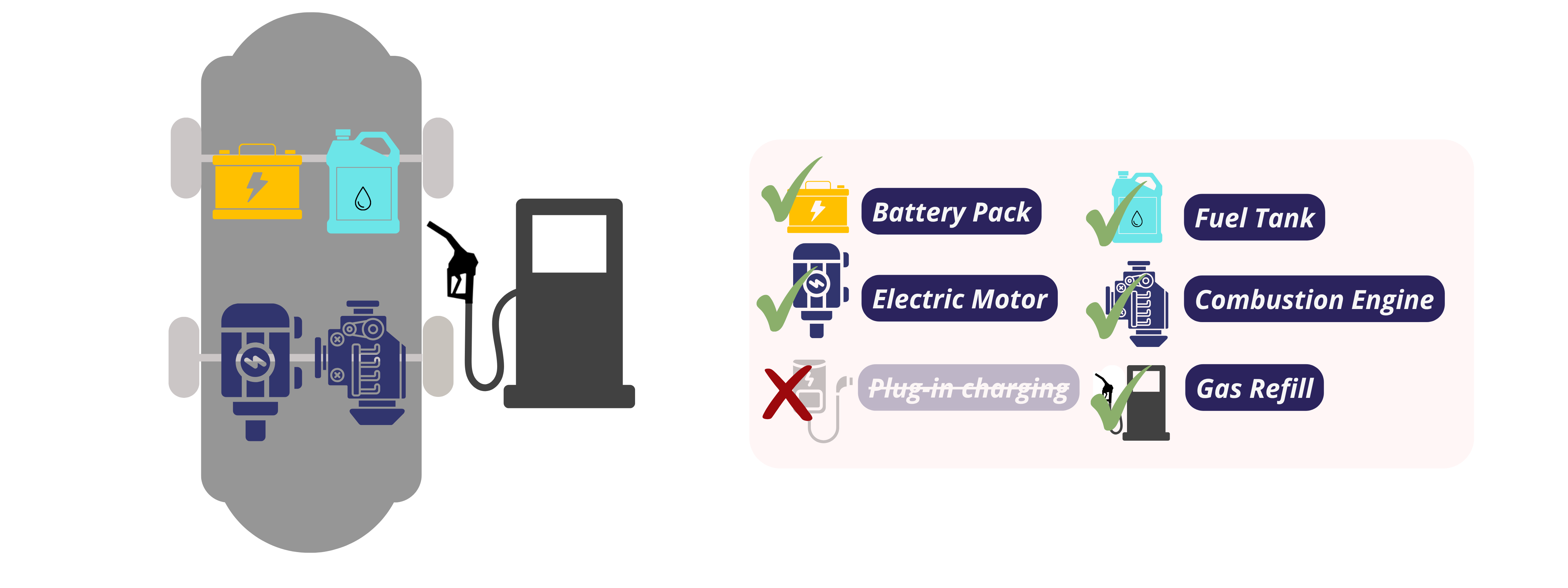

Hybrid Electric Vehicles (HEVs)

HEVs combine a conventional internal combustion engine with one or more electric motors and a battery pack to improve fuel efficiency and reduce emissions. They cannot be charged from an external power source; instead, batteries are charged through regenerative braking.

✅ Pros: Better fuel efficiency than traditional ICE vehicles, No need to plug in, Mature and widely available technology

❌ Cons: Cannot run on electricity alone, Still emits tailpipe emissions, Less environmental benefit than BEVs/PHEVs

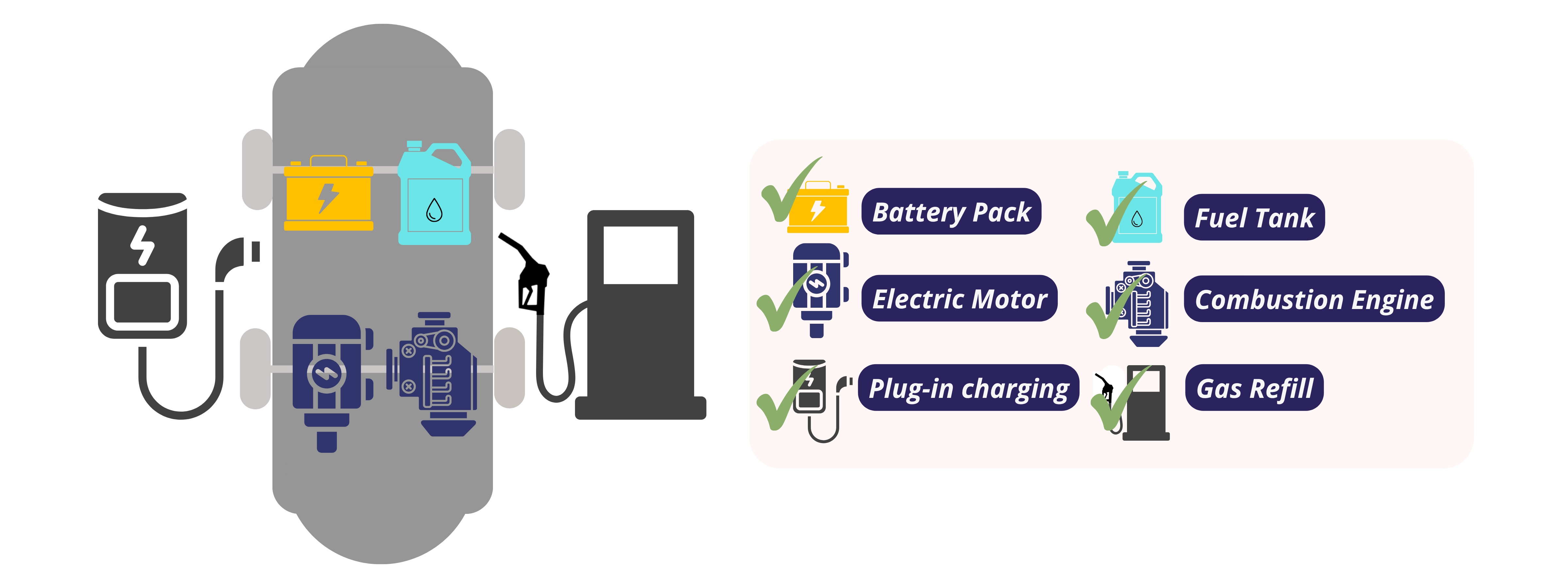

Plug-in Hybrid Electric Vehicles (PHEVs)

PHEVs are equipped with both a rechargeable battery pack and an ICE. The battery can be charged by connecting the vehicle to an external power source (like a home outlet or EV charger), as well as through regenerative braking or the engine itself.

✅ Pros: Can run on electricity for short trips, Backup gasoline engine for longer range, Reduced fuel consumption

❌ Cons: More complex powertrain (engine + battery), Still emits CO₂ when running on gas, Higher cost and maintenance than HEVs

While these EV types may differ in how they source and manage energy, they are all powered by a common set of core components that make electric mobility possible. Let’s take a look at how energy moves within an EV.

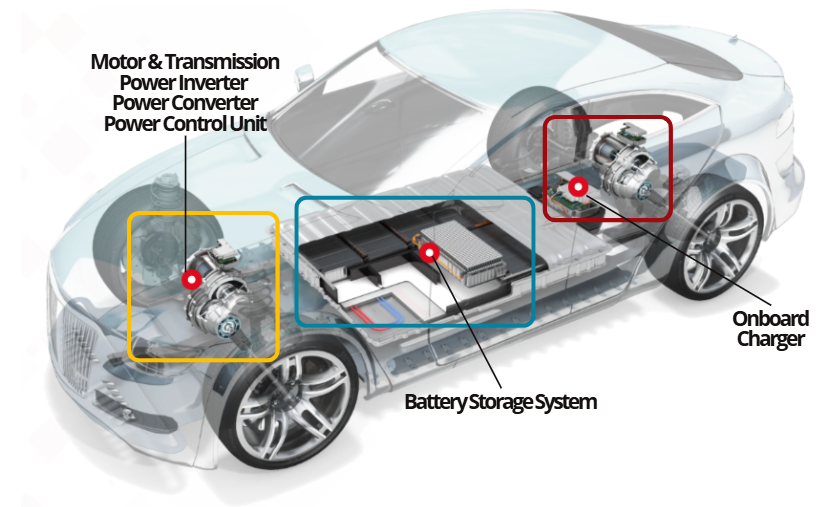

Onboard Charger

The journey begins when the vehicle is plugged into an external alternating current (AC) charging source. The onboard charger converts AC into direct current (DC), which is needed to charge the high-voltage battery pack. It also manages the charging rate, efficiency, and safety protocols of the unit.

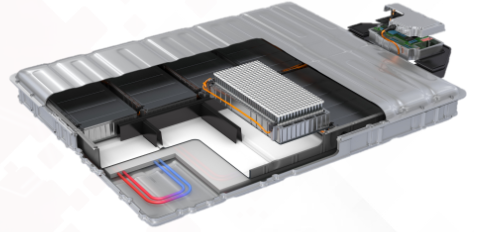

Battery Storage System (Battery pack)

The battery pack acts as the EV’s fuel tank, storing the DC electrical energy. This is typically composed of lithium-ion battery cells and is the primary energy reservoir for all vehicle functions.

DC-DC Converter

From the high-voltage battery pack, the DC–DC converter steps this down to a lower voltage required by the vehicle’s auxiliary systems, such as the dashboards, lights, and sensors.

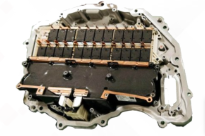

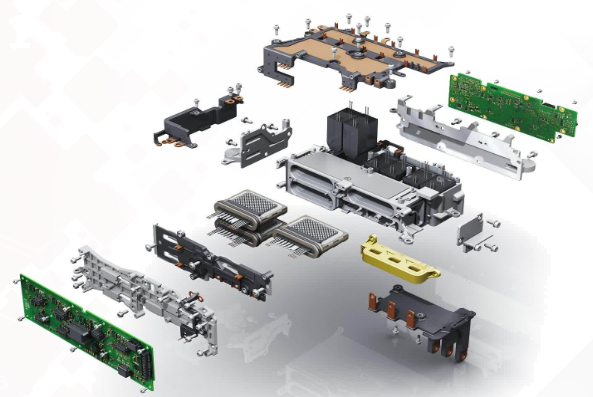

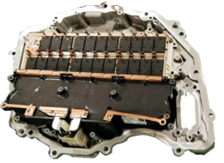

Power Control Unit (PCU)

The PCU manages high-voltage energy flows between the battery, inverter, and motor. It interprets driver inputs and ensures efficient, safe power delivery.

Inverter

The inverter converts the battery’s DC output into AC input for the motor, and vice versa during regenerative braking, recharging the battery.

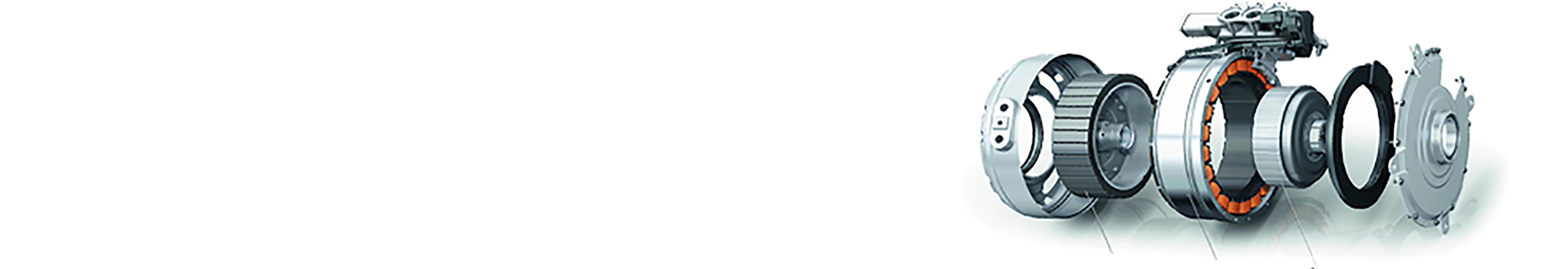

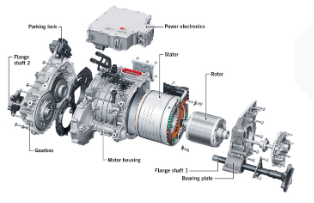

Electric Motor

The motor receives AC power and converts it to mechanical energy to drive the wheels, offering smooth, quiet operation.

Transmission (Reducer)

A single-speed transmission transfers power from the electric motor to the wheels, simplifying the drivetrain and reducing maintenance needs.

This seamless flow of electricity, from the charger to the wheels, illustrates how EVs operate fundamentally differently from gasoline-powered cars. Each component is critical in replacing traditional mechanical systems with a smarter, more efficient electrical alternative. This calls for specialized materials that are just as smart and efficient.

SPECIALTY MATERIALS FOR EMOBILITY

This is where materials matter.

A smarter and greener future calls for smarter and greener materials. Because of the interconnectedness of the eMobility ecosystem, materials are everything. From the interior all the way to the charging stations, each component has to keep up with the changing demands. Learn where specialized materials matter inside (and outside) the eMobility ecosystem below. Click on the items to learn more.

HOW CAPLINQ HELPS DRIVE EMOBILITY FORWARD

CAPLINQ is your trusted partner for specialty chemicals, adhesives, and advanced materials designed to meet the evolving needs of the eMobility revolution. By offering tailored solutions, from battery assembly adhesives to thermal interface materials, CAPLINQ supports automotive manufacturers in enhancing performance, safety, and sustainability.

Our product portfolio for eMobility includes materials such as

Thermal Interface Materials: Polymer-based TIMs infused with different fillers to provide exceptional heat dissipation for EV power electronics and battery packs ensuring optimal performance and reliability under intense thermal loads.

Adhesives: Silyl Modified Polymers (SMP), Two-Part Polyurethane, and reactive hot melt polyurethane (HMPUR) adhesives, engineered for battery cell bonding and electrical insulation.

Coatings and Composites: Epoxy molding compounds, epoxy coating powders, specialty silicons, and composite materials optimized for electrical insulation, mechanical protection, and durability in harsh automotive environments.

CAPLINQ offers solutions that address:

✔️RELIABILITY

Our materials are formulated to enhance thermal stability, vibration resistance, and long-term durability.

✔️PERFORMANCE

We prioritize advanced thermal management, high flexibility, and high-strength materials capable of handling thermal expansion and mechanical stresses.

✔️COMPLIANCE

Our formulations comply with strict environmental and safety regulations, including PFAS-free chemistries and RoHS standards supporting sustainable manufacturing practices.

LEARN MORE ABOUT OUR MATERIALS FOR EMOBILITY

Interested in how CAPLINQ can support your eMobility demands? Learn more about how we help you drive the movement towards a greener future by clicking through the presentation below.

RELATED BLOGS

Because you're here, you might be interested in reading more about:

Thermal Interface Materials In Solar and Wind Renewable Energy Systems

The blog article shown on the left is focused on the application of TIM in Renewable Energy Systems...