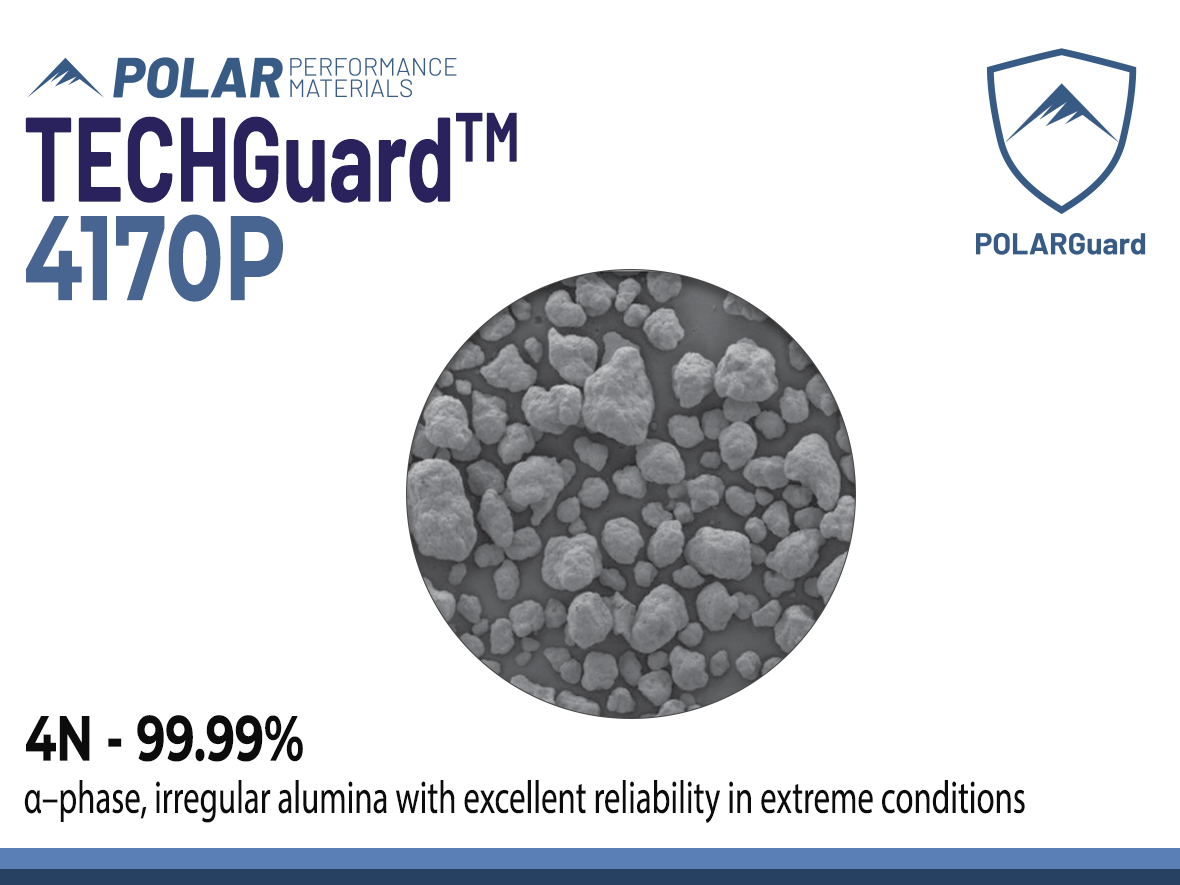

TECHGuard 4170P | 4N Purity Irregular Alumina

- 4N Purity

- 1.4 - 2.0um particle size

- Coatings, aerospace parts, medical ceramics

Product Description

TECHGuard 4170P is a high-purity alumina product characterized by its 4N (99.99%) purity level. It features irregular morphology and a surface area of 4-7 m²/g, optimized for industrial. This material offers consistent performance and low impurity levels, making it suitable for high-tech applications requiring excellent reliability and high purity.

TECHGuard 4170P High Purity Alumina meets the following requirements:

- Manufactured using ISO 9001:2015 Certified processes.

- Ultra-low impurities

- Optimized Surface area

- Process stability

- High temperature resilience

- High quality in harsh conditions

Product Key Features

- Ultra High Purity — Ensuring consistent performance, reliability, and compatibility.

- Precise Particle Size Control — Engineered distribution for optimal packing density, flowability, and surface finish.

- Eco-efficient Manufacturing — Minimizing environmental impact while maximizing purity and quality.

Applications:

- Polar's TECHGuard line of products is engineered for a wider variety of applications, such as those catered towards aerospace, coatings, the medical industry, and Li-ion batteries.

Technical Specifications

| General Properties | |

| Density (g) | 0.3-0.5 g/cm3 |

| Morphology | Irregular |

| Particle size (D50) | 1.4-2.0 um |

| Purity | 99.99 % |

| Surface Area | 4-7 m2/g |

| Chemical Properties | |

| Phase | α |

Additional Information

Frequently Asked Questions about TECHGuard

The TECHGuard line is specifically designed for applications where materials are pushed to their limits. High and low temperature variations, high mechanical strength, and no room for failure. With its 4N-level purity and controlled formats, it supports dense, stable, and defect-resistant parts across spray coatings, ceramics, and structural applications

How is TECHGuard used in Aerospace Applications?

High-purity alumina is used in thermal barrier coatings, wear-resistant ceramic parts, and structural components exposed to extreme heat and pressure. It supports durability and consistency in mission-critical environments. The alumina powder has tight particle size control, low impurity levels, and strong sintering behavior. These properties support clean spray deposition and stable microstructures under thermal cycling.

What documentation is available for aerospace validation?

Polar provides full quality assurance reports, including particle size data, elemental analysis, and batch traceability. This supports customer audits and material validation for regulated programs.

How is TECHGuard used as a coating?

High-purity alumina can be used in thermal barrier coatings and alumina ceramic coatings for high-temperature environments.

High purity alumina can come in either spherical or irregular shapes. Spherical particles are smooth and uniform, offering excellent flow, easy dispersion, and consistent packing. Irregular particles are angular and jagged, providing better mechanical interlocking and abrasion. Spherical morphology is ideal for coatings or pastes, while irregular morphology is ideal for structural ceramics or abrasives.

Can I request a customized particle size?

Yes. Standard distributions and customized sizing is available, including submicron options, to align with your coating or forming process. Our team can match existing specs or develop a tailored grade with full documentation.

How is TECHGuard used in Medical Applications?

TECHGuard High purity alumina is used in medical ceramics that meet stringent performance and compatibility standards. It supports applications where stability is essential, including implantable housings, surgical tools, and diagnostic equipment.

What format of HPA should I use for coating applications?

Powder formats are primarily tailored for coating feedstocks. These are designed for high flowability and predictable deposition, with purity levels up to 5N depending on the application.

| Purity | Key Element Concentration - Less Than (ppmw) | |||

| Na | Si | Ca | Fe | |

| 4N | 30 | 12 | 10 | 8 |

Applications

TECHGuard 4170P is crucial in advanced battery technologies, especially for enhancing thermal management and safety in battery systems. One of its primary applications is in lithium-ion batteries (LiBs), where it serves as a coating for the battery separator, which lies between the cathode and anode. By coating the separator with TECHGuard 4170P, thermal shrinkage is significantly reduced, preventing potential short circuits that could compromise the battery’s safety. Additionally, the coating helps inhibit dendrite growth, which can adversely affect lithium-ion transport, further enhancing the battery's performance and longevity.

4170P is also highly compatible with various coating processes. Its uniform particle size and spherical shape allow for easy dispersion into different matrices, forming stable suspensions essential for creating smooth, defect-free coatings. This makes it particularly advantageous for applications like LED phosphor coatings or protective layers in electronic devices, where surface consistency and uniformity are critical for optimal performance.

Note: Alumina coated battery separator prevent thermal shrinkage during high temperature operations.

Reference: Research Study: Preparation of a high-purity ultrafine α-Al2O3 powder and characterization of an Al2O3-coated PE separator for lithium-ion batteries by Dong-Won Lee, Sang-Hun Lee, Yong-Nam Kim, and Jong-Min Oh

What is the consequence of an unreliable battery separator?

With increases in battery energy density, voltage and packing size, battery materials become less and less electrochemically stable. It is reported that an unusually thin monolayer and an aggressive increase in battery energy, plus other manufacturing defects in the battery used in the Galaxy Note 7 resulted in a total product recall of their Galaxy Note 7 mobile phone.

Samsung’s investigation confirmed that the fires in the devices were caused by separate battery issues from two different suppliers. The third-party testing company, Underwriters Laboratories (UL), tested the batteries from 'Company A' and 'Company B', believed to be SDI and ATL, respectively. UL discovered that SDI batteries had internal short circuits caused by damage, while some undamaged batteries had deformed top right corners, and some negative electrodes were too long. For the ATL batteries, UL found that some lacked insulation tape, and in other cases, the insulation was damaged by protruding welds. These issues could lead to short circuits, overheating, and even explosions. After recalling phones with SDI batteries due to a design flaw that increased the risk of short circuits, Samsung replaced them with ATL batteries. However, manufacturing defects in the ATL batteries also caused explosions, leading to a second recall. This heavily damaged consumer trust and brand image, ultimately forcing Samsung to discontinue the production of the Note 7 to prevent further losses.

Thermal Interface Fillers

High Purity Alumina (HPA) is an excellent filler for Thermal Interface Materials (TIMs) due to its superior thermal conductivity, dielectric properties, and chemical stability. The usual HPA grade used as fillers are the 3N grades as their particle size are suited for managing the heat pathways across the thermal interface. It enhances the heat dissipation capabilities of TIMs by improving thermal transfer between electronic components, reducing the risk of overheating. The fine particle size of HPA ensures that the TIM maintains a consistent bondline thickness and fills in micro-gaps effectively, resulting in better surface contact and improved heat conduction. Additionally, HPA’s resistance to high temperatures and chemical inertness make it ideal for use in demanding environments such as power electronics, LEDs, and high-performance computing systems. Its dielectric nature ensures that it doesn't interfere with electrical performance, making it an essential component in electronic cooling applications.

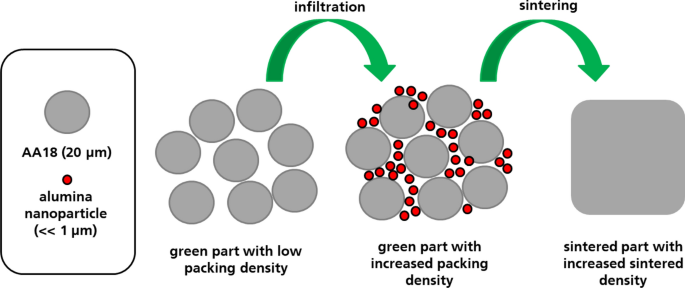

TECHGuard 4170P is particularly well-suited for sintering processes used in the production of high-performance ceramics and components. Its spherical morphology and controlled particle size contribute to uniform packing density and low porosity in sintered products, leading to enhanced mechanical strength, thermal stability, and electrical insulation properties of the industrial ceramic.

One of the most significant applications of alumina in the ceramics industry is as a refractory material. Due to its high melting point, alumina is used as a lining material in high-temperature furnaces and kilns in applications where contaminants should be virtually non existent. Alumina also provides excellent thermal shock resistance, making it an ideal material for use in refractory applications. Alumina is also used as a grinding media in the ceramics industry. The hardness and wear resistance of alumina make it an ideal material for use in grinding applications. Alumina grinding media are used in ball mills, vibratory mills, and other types of grinding equipment.

TECHGuard 4120P is especially engineered for high-performance aerospace ceramics and components.

In aerospace and industrial ceramics, high purity alumina is often used as a refractory material, capable of withstanding extreme temperatures with minimal contamination. Its excellent thermal shock resistance makes it ideal for furnace linings, high-temperature tooling, and components exposed to rapid temperature changes. Additionally, alumina’s hardness and wear resistance make it suitable as grinding media in the preparation of ceramic powders, ensuring consistent particle size and quality in critical aerospace manufacturing processes.

TECHGuard 4120P is especially engineered for high-quality and biocompatible medical components.

Producing ultra-high-purity alumina for medical ceramics is uniquely demanding. Materials must be ultra-pure to avoid trace contaminants like Fe or Na that can cause inflammatory reactions or device failure. At the same time, they must offer high strength and wear resistance, with tight control of particle size and morphology to ensure dense, defect-free ceramics. Add the need for regulatory compliance—with full traceability and qualification to standards like ISO 13485—and it becomes clear: medical-grade ultra-high-purity alumina requires precision across purity, performance, and documentation

Industrial Processing Compatibility

Pressing and Forming of a Green Body part

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) Coating Technique

Additive 3D Printing

Pressing and Forming

In pressing and forming applications, such as powder metallurgy or ceramic shaping, TECHGuard 4170P's consistent particle size and spherical shape allow for excellent flowability and compaction. This ensures uniform density and minimal defects in the green body, which are crucial for achieving high-quality finished parts. The material's low impurity levels further reduce the risk of contamination, making it suitable for high-precision components.

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)

For applications involving thin film deposition techniques such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD), TECHGuard 4170P's high purity and uniform particle size are critical. These characteristics ensure the production of films with consistent thickness, uniform coverage, and minimal defects, which are essential for producing high-quality, functional surfaces in semiconductor and optical applications.

Additive Manufacturing (3D Printing)

With the rise of additive manufacturing, TECHGuard 4170P has proven to be an excellent material for 3D printing high-performance ceramic components. Its fine, uniform particles and high surface area enable precise layer-by-layer deposition, resulting in parts with superior detail and complexity. The material’s thermal conductivity and stability also make it suitable for printing components that require excellent heat dissipation or insulation, such as in electronic devices or thermal management systems.

Customized Solutions

TECHGuard 4170P is produced using advanced manufacturing techniques that ensure high consistency and quality. Our state-of-the-art processing technology guarantees minimal contamination, making it a reliable choice for demanding applications. We offer customizable solutions to meet specific requirements, supported by expert technical assistance and collaborative R&D efforts.