LOCTITE ABLESTIK NCF 218

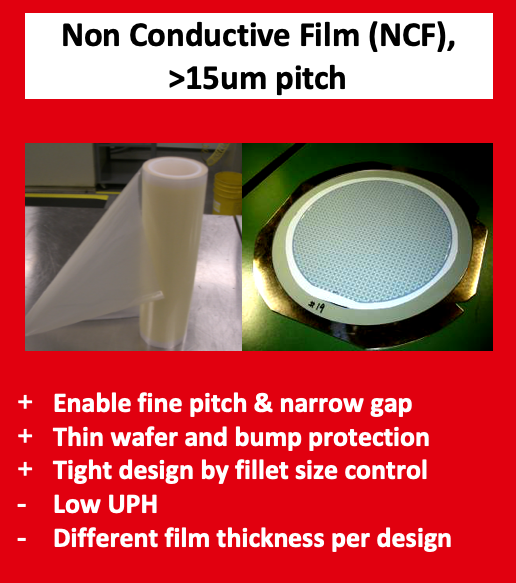

- Non conductive Underfill film

- Enables fine pitch, narrow gap Cu pillar

- TSV, Die to die & Die to substrate

Product Description

LOCTITE ABLESTIK NCF 218 Non conductive Underfill film is specially formulated for Pb free, low κ, thin gap, large and thin die that are being used in advance flip chip applications. It is an ideal material for 3d die stacking in memory devices.

LOCTITE ABLESTIK NCF 218 is mainly used for Flip chips with bumps and pillars. Its main function is to fully encapsulate the tiny and fragile bumps/pillar interconnects and reinforce and destress the joints during temperature cycling tests. Additionally, it contains a fluxing agent that improves the interconnections between the bumps and the substrate.

LOCTITE ABLESTIK NCF 218 is suitable for die to die, die to wafer (TSV) or die to substrate applications. It is a 2 in 1, BMI based, heat curable yellow film that is typically used for Thermal compression bonding. The standard NCF 218 film has 18um layer thickness but it can also service thicknesses ranging from 15 to 40um.

Cure Schedule

- 30 minutes ramp to 175ºC, hold 2 hours @ 175°C

Technical Specifications

| Thermal Properties | |

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 119 °C |