Capacitors

What is a capacitor?

A capacitor is an electrical component used to store electrical charges and can supress electrical noise and voltage spikes, smoothing any severe voltage fluctuations in the system.

They are constructed by two conducting, typically aluminum, plates separated by a dielectric such as plastic, paper, mica film, ceramic and even vacuum.

Their ability to charge and store charge allows timed circuits to delay electronic devices from turning on or off. This charging capacity can keep a circuit operating for a certain period of time after it has been shut down. Other than energy storage they can be used for power conditioning and correction, supression and coupling, sensing, oscilalting and more. Nowadays it is very hard to find any electrical product without one type of capacitor or another.

Overview of Capacitors

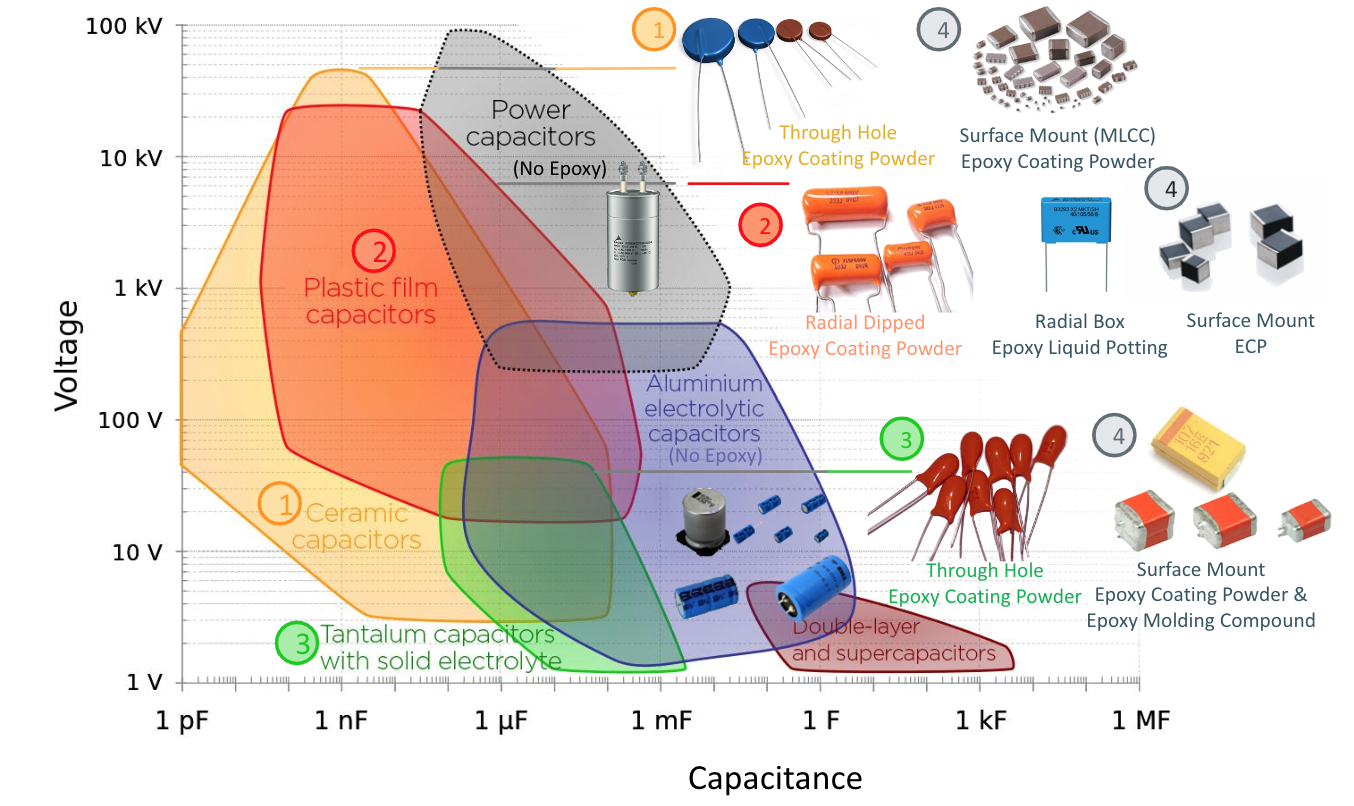

Relative Voltage and Capacitance Capabilities

Types of Capacitors

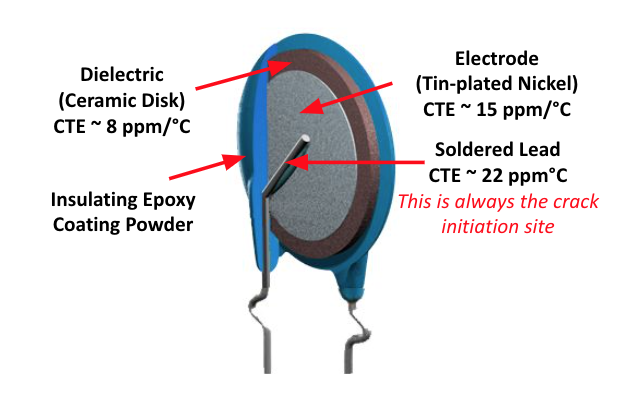

Class 1 Ceramic Capacitors - Ceramic capacitors are made out of ceramic that is not affected by temperature changes. It is composed of an electrode, a ceramic disk, a soldered lead, and a protective insulating layer of epoxy coating powder. Class 1

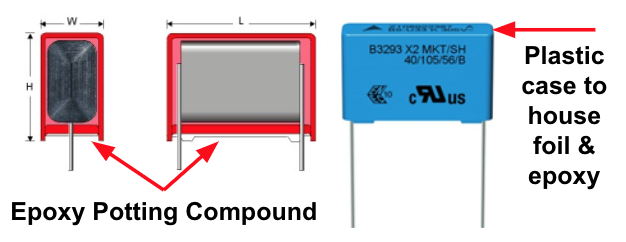

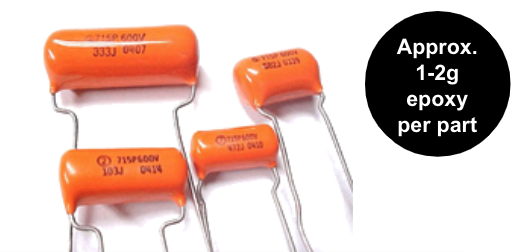

Film Wrap Capacitors - Film wrap capacitors combine plastic films (dielectric) with thin metal foils (electrode). Mechanical protection of this assembly can be done in two ways, including liquid epoxy potting or epoxy coating powder. Compared to ceramic capacitors, film wrap capacitors cannot take the high temperatures of ceramic capacitors

Liquid Epoxy Potting Epoxy Coating Powder

Through-Hole Tantalum Capacitors - Tantalum capacitors consists of a material called tantalum, which is a very porous material. These capacitors distinguish themselves from other capacitors in having high capacitance per volume and weight. Niobium is in direct competition to tantalum, is considerably less expensive and is more readily available.

Epoxy molding compounds for Capacitors

| Product | Key Feature |

| Hysol GR 2220 | Designed for molding of MnO based tantalum capacitors; Lower cost; High productivity |

| Hysol GR 2310 | Standard material designed for tantalum and niobium capacitors using MnO |

| Hysol GR 2320 | |

| Hysol GR 2330 | |

| Hysol GR 2710 | Low stress; Designed for auto-molding of polymer and aluminium capacitors |

| Hysol GR 2720 | |

| Hysol GR 600 | Low moisture absorption;high reliability for aluminum capacitors |

| Hysol GR 2811 | Ultra-low stress; High crack resistance for automolding of conductive polymer especially with thin wall |

| Hysol GR 2812 | Up to MSL3; Low ESR; Low leakage; Low stress |

| Hysol GR 2820 | Low ESR; Low leakage; Low stress; Suitable for conductive polymer tantalum capacitors |

| Hysol GR 2822 | Up to MSL3; Low ESR; Low leakage; Low stress; |

All products are "Green"

Epoxy Coating Powders for Capacitors

GCP18-05: Halogen-Free Epoxy Coating Powder for Passive Electronic Components

LINQSOL™ GCP1805 is an insulating epoxy coating powder for capacitors, varistors, and other passive components. It was designed specifically as a halogen-free version of DK18-05 with similar technical specifications, just without containing any of the halogens. It can be applied through a fluidized bed with temperatures as low as 105°C. Its excellent curing conditions make the epoxy coating powder also very suitable for tantalum capacitors and other temperature-sensitive devices.

Linqsol GCP1805 is an UL 94 V-0 listed halogen-free product and pass UL RTI rating of 130 °C. With excellent dielectric properties and low moisture absorption, GCP1805 works best for your passive component applications, including capacitors, resistors, inductors, etc.