Melamine Cleaning Compounds

Semiconductor mold cleaners are compounds that clean the culls, runners and chases of your transfer-grade or compression-grade molds used for thermoplastic and thermoset plastic materials. These materials are used to remove all the stains, residues and build-up that occur after running 50, 300 or 800 shots of thermoset epoxy molding compounds.

Mold cleaning compounds are popular because they are drop in cleaning solutions. You just load your regular machine with the compound, run a few cycles and you are good to go. Another advantage is that they are not just cleaning residues. During the molding process there are also small amounts of epoxy that remain stuck as well as waxes and stains coming from the epoxy molding compound. That's where our cleaning compounds come in, removing stains and pollutants without requiring preheating and without abrasion or corrosion.

Please continue to our Learn More section to learn about what types and forms of semiconductor mold cleaners are available, the differences in their types and application methods and how CAPLINQ can help you select the best mold cleaning product for your application.

MCL-C10 | Melamine Compression Cleaning Material

- 0.07% Formaldehyde

- Compression grade

- Suitable for transfer mold equipment

- 1 - 2 weeks

MCL-C11 | Melamine Compression Cleaning Tablets

- 3.6% Formaldehyde

- Compression Grade

- Suitable for EMC

- In stock

MCL-C12 | Melamine Compression Cleaning Tablets

- 1.7% Formaldeheyde

- Compression Grade

- Suitable for Semiconductor EMC

- 6 - 8 weeks

MCL-T20 | Melamine Transfer Cleaning Pellets

- Excellent Cleaning Efficiency

- Ideal for High-Precision Industries (Electronics and Automotive)

- Enhanced Mold Lifespan and Minimized Downtime

- 8 - 12 weeks

MCL-T33 | Melamine Transfer Cleaning Tablet

- Transfer grade

- Designed for semiconductor molds

- High adhesive strength

- 8 - 12 weeks

Product Selector Guide

| Product Name | Technical Specifications | Comments | ||||

|---|---|---|---|---|---|---|

| Package | Application method | Formaldehyde | Mold Temperature (°C) | Curing Time (min) | ||

| MCL C10 | Melamine Powder | Compression | 0.1% | 150 - 190 | 2 - 5 | Minimal Formaldehyde and great performance. Granular/powder. |

| MCL C12 | Melamine Tablets | Compression | 1.7% | 170 - 180 | 5 - 8 | Low Formaldehyde and suitable for Semiconductor EMC in various cleaning processes |

| MCL T20 | Melamine Pellets | Transfer | 0.1% | 160 - 190 | 4 - 10 | Ideal for high precision industries, prolonging the operational lifespan of molds |

| MCL-T33 | Melamine Pellets | Transfer | 2 - 2.5% | 160 - 190 | 6 - 10 | Strong cleaning performance, Compatible with wide range of mold cavity designs |

| MCL-C11 | Melamine Tablets | Compression | 2 - 2.5% | 160 - 190 | 6 - 10 | Strong cleaning performance,restores mold surface integrity, prolongs tooling lifespan |

*Compression cleaning products are suitable for transfer molding equipment. Do not confuse the application method with the epoxy molding equipment.

| Method | Type | Advantages | Disadvantages | Synergies |

|---|---|---|---|---|

| Compression | Tablets | Easy to use under standard molding conditions Standard removal process as normal molding Effective for cleaning large cavities and large molds | More shots to clean mold Does not clean land areas | Dissolving Rubber sheets can be used to soften residues before application |

| Compression | Sheets | Cleans fast Easy to remove from the mold | Increased cost per shot | A melamine shot may be needed to remove film left by the rubber sheets |

| Transfer | Pellets | More effective cleaning Cleans both cavities and land area | Slightly Longer clean up time Can damage mold if misused | Can be used before Cleaning Sheets for Enhanced cycles |

Learn More

Semiconductor Mold Stains and how to Clean your mold die cavities and surface

The encapsulation of semiconductors like integrated circuits, central processing units, memory devices, and capacitors is actually a fairly simple and straight-forward process. Nine times out of ten, semiconductors are encapsulated by an Epoxy Molding Compound : usually in a transfer molding, or compression molding process.

In both cases, the semiconductor components are placed into the cavity of a mold and then a molding compound is liquefied by heat and/or pressure and pumped into that cavity. This results in the semiconductor being fully enclosed in a protective epoxy shell.

In theory, you then pull the finished encapsulated semiconductor out of the mold cavity and put the next set of semiconductor components in and repeat. However, in practice, stains build-up on the surface of mold die, particularly in the nooks and crannies and along the edges of the cavity. Over time the layer of residue thickens so much it forms a burr along the periphery of the cavity and negatively impacts the quality of the finished part. That\'s why cleaning and conditioning your molding tools can prevent molding defects.

Where do semiconductor mold surface stains and build up come from?

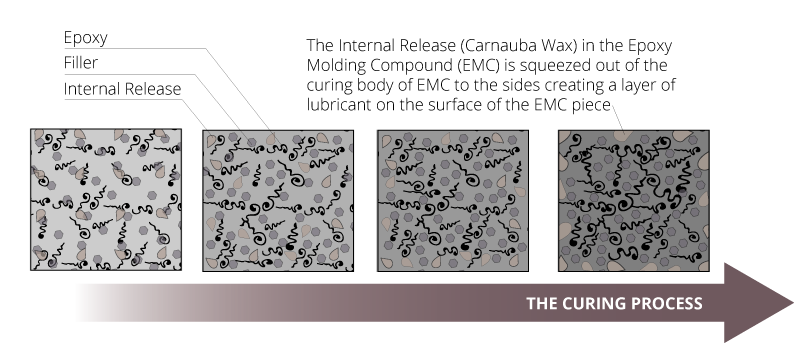

Epoxy is naturally super adhesive. So along with fillers, pigments, hardeners, and catalysts, an internal release agent is usually also mixed into the final composition of an epoxy molding compound. The internal release agent (usually carnuba wax because of its high compatibility with epoxy) oozes out of the epoxy molding compound as the epoxy itself cures. This allows the final part to release from the mold easily.

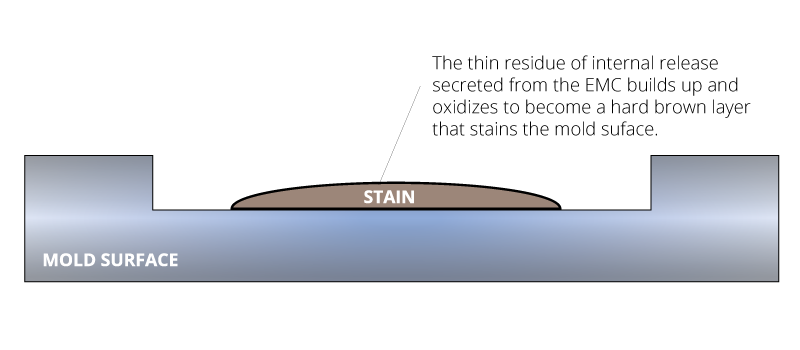

However, over time the internal release agent forms a residue, along with other contaminants, and gets trapped in the microporous structure of the metal mold, and eventually oxidizes to form a hard layer. This is the main origin of mold die stains. Other sources include epoxy residue, resin bleed, and solder flux residue.

Eventually this layer of oxidized internal release agent builds up on the mold tools surface: contributing to mold defects, loss of glossy surface quality on the part, and ironically making it harder to release the part from the mold! So obviously, after a certain number of runs, every semiconductor molding operation needs some down time to clean the molds.

Cleaning the mold surface and cavity: then and now

Semiconductor mold production lines spit out thousands of finished fully encapsulated semiconductors every few seconds. Not cleaning the build of stains and residue can save you downtime in the short-term but means that at some point you will have to completely stop production to clean your mold dies.

On the other hand, regularly cleaning involves some downtime for some machines, but, in general, production can keep going. The faster you clean the mold the less downtime you will have, and this is the most important factor when trying to fit a cleaning procedure into your production cycle.

A copper brush and some manual labor is still one of the most effective cleaning methods. However, with a mold at 180c or more, how effectively can any line technician really be? And do you really want to turn the mold off to let it cool, then clean it, and then bring it back up to temperature? That would mean hours of downtime. If you have to, then you have to, but there are alternative ways of cleaning the mold die that require less downtime.

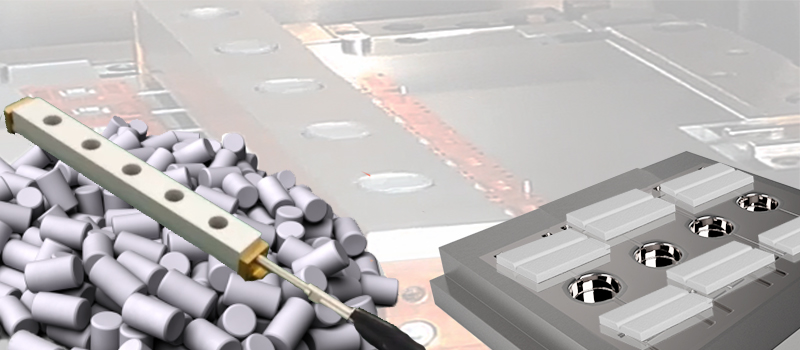

Melamine Mold Cleaning Compound – CHEMLINQ ™

Transfer and Compression grade Melamine compounds have been the industry standard for semiconductor mold cleaning a long time now . That’s because they don’t require downtime. Instead, they function like your regular Epoxy Molding Compound pellets: you simply load them into your normal pellet jig and run the machine as you would normally. This means that they can effectively clean your mold during production without shutting down machines. Same goes for compression grade Melamine Cleaning Compound.

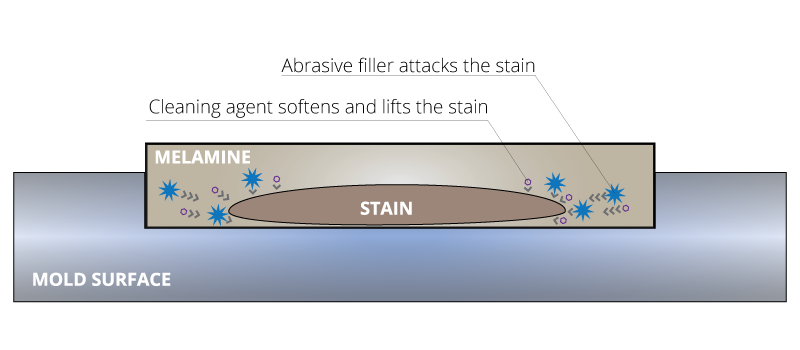

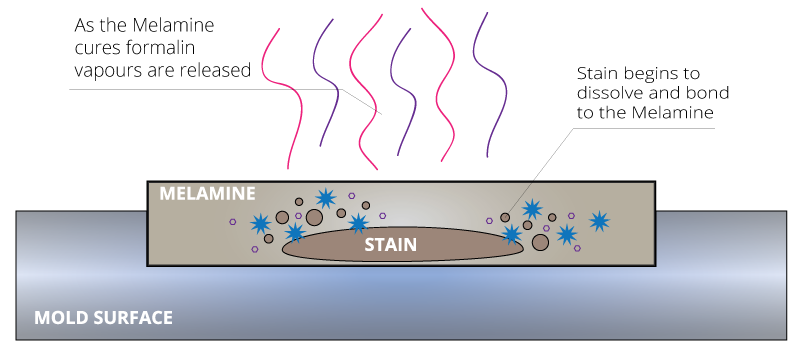

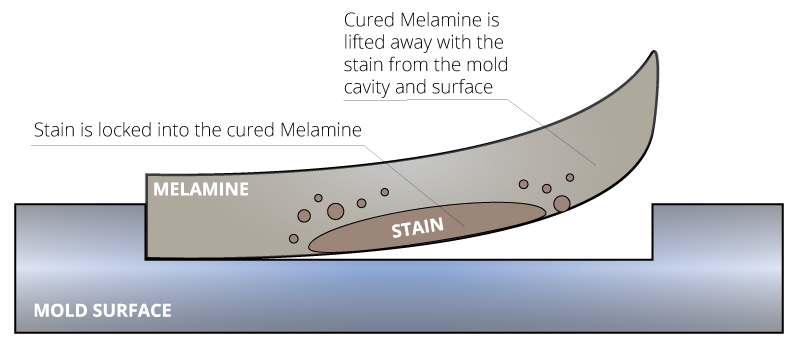

Melamine cleans the mold by adhering to stain and peeling it off the surface of the mold when Melamine is peeled off. It also contains an abrasive filler which grinds and attacks stains as it flows through mold die channels and cavities. Another important way it attacks stains is with additives which dissolve the stain and bind it to the Melamine. This reduces the phase boundary between the stain and the mold: allowing the stain to come off more easily when you peel the cured melamine out of the mold cavity.

- Use your standard molding conditions

- Use the same volume of melamine as molding compound (the specific gravity may be different)

- Mold at 170-180 °C for 5 minutes

- When the press opens, remove the cured parts and runners

- Inspect the parts and cavities for staining

- Repeat the above steps until the mold is completely clean and stains are no longer transferred to the cured molding compound

- Reduce the clamp pressure by at least 50% to avoid damaging the delicate positioning pins

- Place the melamine preforms over the cavities and runners

- Close mold and cure for 5 minutes

- When the press opens, remove the cured melamine

- Check melamine and mold cavities for stain

- Repeat the above steps until the mold is completely clean

The semiconductor industry as a whole is, however, moving away from Melamine as a mold cleaning compound. That is because cured Melamine is hard to remove from mold cavities and it produces formalin as it cures. Formalin is an aqueous form of Formaldehyde, and so the vapors produced by Melamine cleaning compound are carcinogenic and very dangerous for human health.

Regulations such as the EU’s REACH places formaldehyde on the substance of high concern list. This makes importing and using Melamine quite legally challenging in some situations. That’s why CAPLINQ’s R&D department is working on developing a new Melamine compound with less than 0.1% formaldehyde to make it meet REACH standards, as well as formaldehyde-free formulations for our melamine cleaning compound.