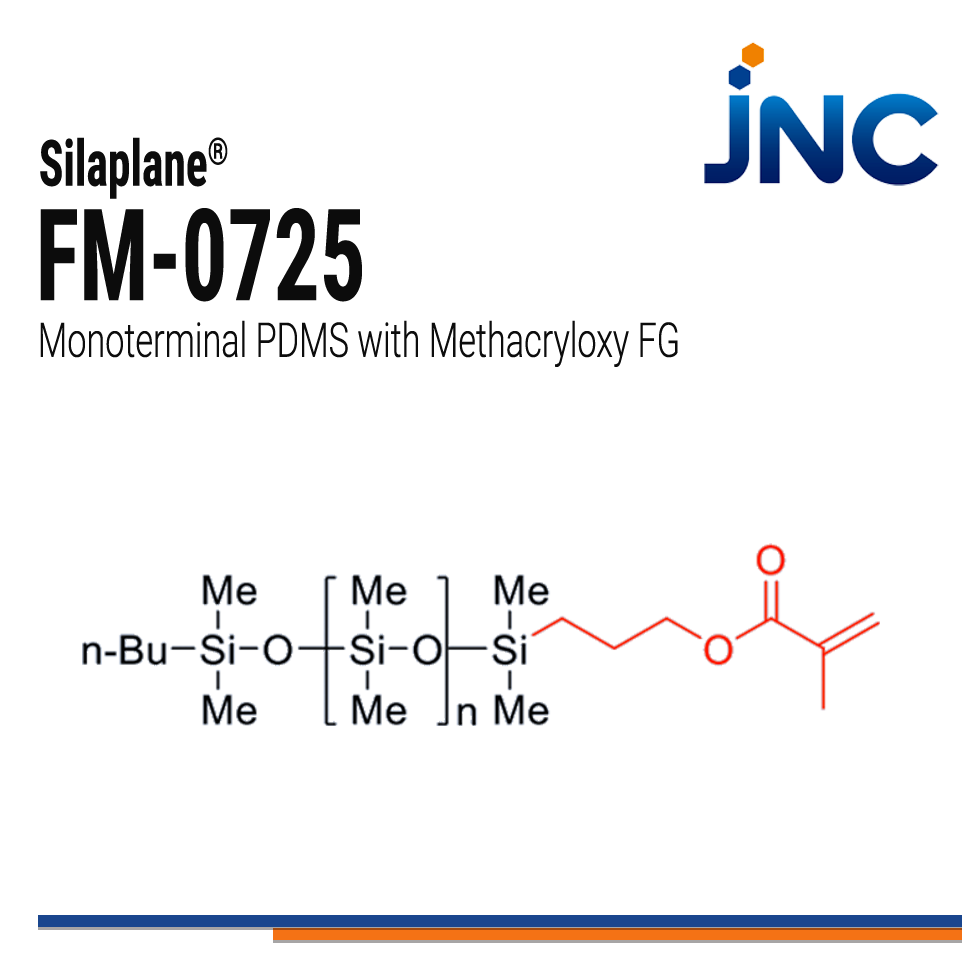

FM-0725 | Reactive PDMS - Monoterminal Methacryloxy

- Mono terminal

- 10,000 g/mol | 200 mPas

- Methacryloxy functional group

Product Description

Silaplane® FM-0725 is a reactive polydimethylsiloxane (PDMS) based polymer with a molecular weight of 10,000 g/mol and a Viscosity of 150-260 mPas. This reactive silicone material offers the addition of silicone-type properties to non-Silicone materials in a variety of industries including electronics, semiconductors, automotive, biotech, healthcare, and clean energy applications. It offers narrow polydispersity and a low level of chemical impurities.

Silaplane® FM-0725 mono-terminal product has a Methacryloxy functional group that is reactive toward a variety of compounds and surfaces enabling chemical and physical changes to chemicals, particle surfaces and larger surface structures. Methacryloxy groups are mainly reacting with Acrylic resins.

Product Benefits:

- Water/Oil repellency

- Gas permeability (Oxygen, CO2, CH4, etc.)

- Mold releasability

- Anti-Abrasion resistance, Anti-fouling

Technical Specifications

| General Properties | |

| Molecular weight | 10000 g/mol |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 0.97 |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 200 mPa.s |

Additional Information

FM-0725 is suitable for use in UV curing systems but is not specifically designed to enhance adhesion. However, its silicone component may contribute to increased flexibility in the resin, which could indirectly influence adhesion performance.

In some systems, the long silicone chain of FM-0725 may present compatibility challenges. In such cases, using a version with a shorter molecular weight may be more effective, though it would offer a more limited improvement in flexibility.