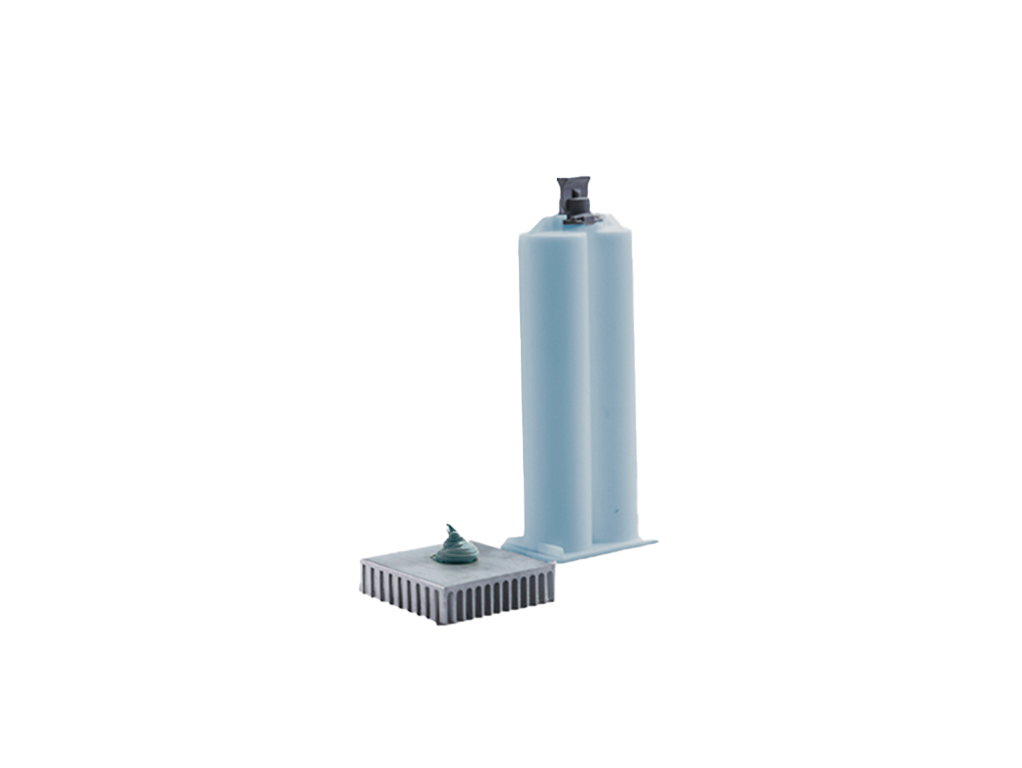

HLP 2000 | Two part Thermal potting material

- Low Viscosity

- 2.0 Thermal Conductivity

- Room temperature cure

Product Description

Honeywell HLP2000 is a two-part, silicone-based thermal potting material designed to provide both superior heat dissipation and protective encapsulation for sensitive electronics. With a thermal conductivity of 2.0 W/m·K and low viscosity (6000 cps), it flows easily to encapsulate components, making it ideal for automotive, LED, photovoltaic, and industrial power applications.

Honeywell HLP2000 cures at room temperature and can be heat-accelerated for faster processing. Beyond thermal management, HLP2000 also safeguards electronic assemblies from environmental stress—like humidity, dust, or vibration—extending the operational life and reliability of the complete module.

Applications

Automotive electronics

Industrial power supplies

Photovoltaic inverters

LED modules and lighting systems

Technical Specifications

| General Properties | |||||

| Color Color The color | Grey | ||||

| Mix Ratio Mix Ratio The amount of a constituent divided by the total amount of all other constituents in a mixture | 1:1 | ||||

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 2.2 | ||||

| |||||

| |||||

| Physical Properties | |||||

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 6000 mPa.s | ||||

| Mechanical Properties | |||||

| |||||

| Electrical Properties | |||||

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 1.0x1015 Ohms⋅cm | ||||

| Thermal Properties | |||||

| Operating Temperature | -40 - 200 °C | ||||

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 2.0 W/m.K | ||||

| UL 94 Rating UL 94 Rating Flammability rating classification. It determines how fast a material burns or extinguishes once it is ignited. HB: slow burning on a horizontal specimen; burning rate less than 76 mm/min for thickness less than 3 mm or burning stops before 100 mm V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed. V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole. 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole | V-0 | ||||

| Curing Conditions | |||||

| |||||

Additional Information

Storage and Handeling

- Shelf life: 9 months at Room Temperature

- Storage: Store in a well-ventilated area. Keep the container closed when not in use, and keep it away from direct sunlight.

- Processing: Mix at a 1:1 ratio by weight. The material cures in 24 hours at room temperature or within 1 hour at 80 °C. Before use, ensure both parts are thoroughly mixed. Store in a well-ventilated area and protect from direct sunlight. Always keep containers sealed when not in use.