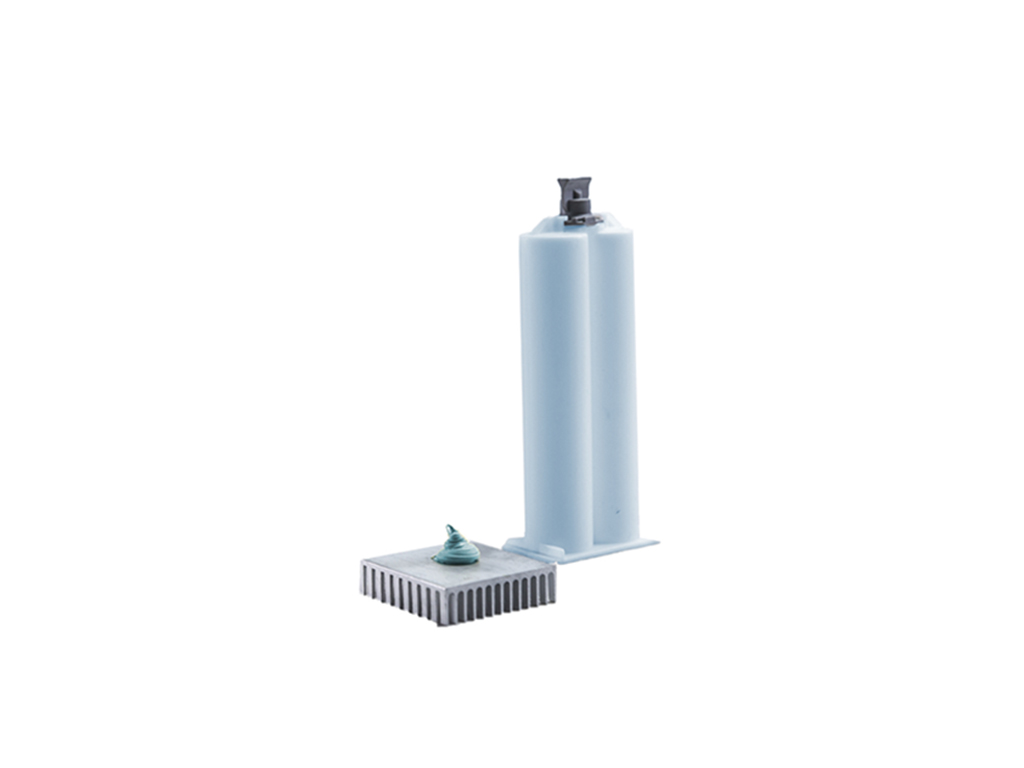

HLT 3000 | Two part Hybrid Thermal Gel

- Blue + White

- 3.0 Thermal Conductivity

- Stencil Printable

Product Description

Honeywell HLT3000 is a two-part, dispensable thermal gap filler with low viscosity and good thixotropy properties that allows it to be stencil printable. This gap filler is silicone based and is easy to dispense and print after 1:1 mixing. It can be a great replacement for thermal grease if you're facing pump out issues and it can offer all the benefits and reliability of gel materials in a printable form, without having to invest in dispensing equipment.

Honeywell HLT3000 passes the rigorous automotive vibration testing without oil bleeding and is formulated to balance thermal performance, phase separation and long term reliability. Additionally it has no moisture absorption at all, post D85 testing. With its high compressibility, it is designed to minimize thermal resistance at interfaces and suitable for thin bond line applications. The material is available in 200+200cc syringes, 1+1 gallon and 5+5 gallon jars

The product can be cured either for 18 hours at Room temperature or 20minutes at 120°C. Of course those are just indications and you can experiment with curing for your application needs.

Technical Specifications

| General Properties | |

| Color Color The color | White - Blue |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 3.1 |

| Thermal Properties | |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 3.0 W/m.K |

| Thermal Impedance | 0.45 °C·cm²/W |

| Electrical Properties | |

| Dielectric Strength Dielectric Strength Dielectric strength is measured in kV per mm and is calculated by the Breakdown voltage divided by the thickness of the tested material. Those two properties go hand in hand and while Breakdown voltage is always thickness dependent, dielectric strength is a general material property. As an example, the dielectric strength of Polyimide is 236 kV/mm. If we place 1mm of Polyimide between two electrodes, it will act as an insulator until the voltage between the electrodes reaches 236 kV. At this point it will start acting as a good conductor, causing sparks, potential punctures and current flow. | 10 kV/mm |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 1.0x1013 Ohms⋅cm |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 100,000 - 200,000 mPa.s |