LOCTITE FP4804 | Epoxy Underfill

- Good flowability

- Low CTE/modulus (reduced stress)

- No resin bleed out on glass

Product Description

LOCTITE ECCOBOND FP 4804 is a high-performance, silver-free epoxy underfill material developed to deliver improved adhesion and reduced stress in electronic packaging. Based on the same chemistry as the popular FP4802, FP 4804 builds on its predecessor with a higher filler content (78%), resulting in a significantly lower coefficient of thermal expansion (CTE) and modulus—crucial for minimizing thermal stress.

With a cohesive failure mode in die shear testing and zero resin bleed on glass substrates, LOCTITE ECCOBOND FP 4804 ensures high-reliability bonding and a clean finish, even in precision applications. It also features a robust dispense profile that remains stable during extended work periods, making it ideal for use with jet dispensing systems.

Applications

- Underfill for flip-chip and BGA components

- Semiconductor packaging requiring high adhesion and low CTE

- Automotive-grade electronics meeting AEC Grade 1 standards

- Jet dispensing processes for fine-feature electronics

Technical Specifications

| General Properties | |||||||||

| Filler Content | 78 % | ||||||||

| Pot Life Pot Life Pot life is the amount of time it takes for the viscosity of a material to double (or quadruple for lower viscosity materials) in room temperature after a material is mixed. It is closely related to work life but it is not application dependent, less precise and more of a general indication of how fast a system is going to cure. | 24 hours | ||||||||

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 1.84 | ||||||||

| |||||||||

| Physical Properties | |||||||||

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 102000 mPa.s | ||||||||

| Chemical Properties | |||||||||

| |||||||||

| Moisture absorption | 0.3 % | ||||||||

| Mechanical Properties | |||||||||

| |||||||||

| Thermal Properties | |||||||||

| |||||||||

| |||||||||

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 51 °C | ||||||||

Additional Information

Cure schedule

Recommended cure condition

• 30 min ramp to 100°C, soak 2hrs at 100°C, then ramp 30min to 150°C, soak 1hr at 150°C

Alternate cure condition

• 30 min ramp to 100°C, soak 1hr at 100°C, then ramp 30min to 150°C, soak 2hrs at 150°C

Bleeding test FP4802 & FP4804

Die Shear test FP4802 & FP4804

Printing and dispensing

Thawing (if applicable)

1. Allow container to reach room temperature before use.

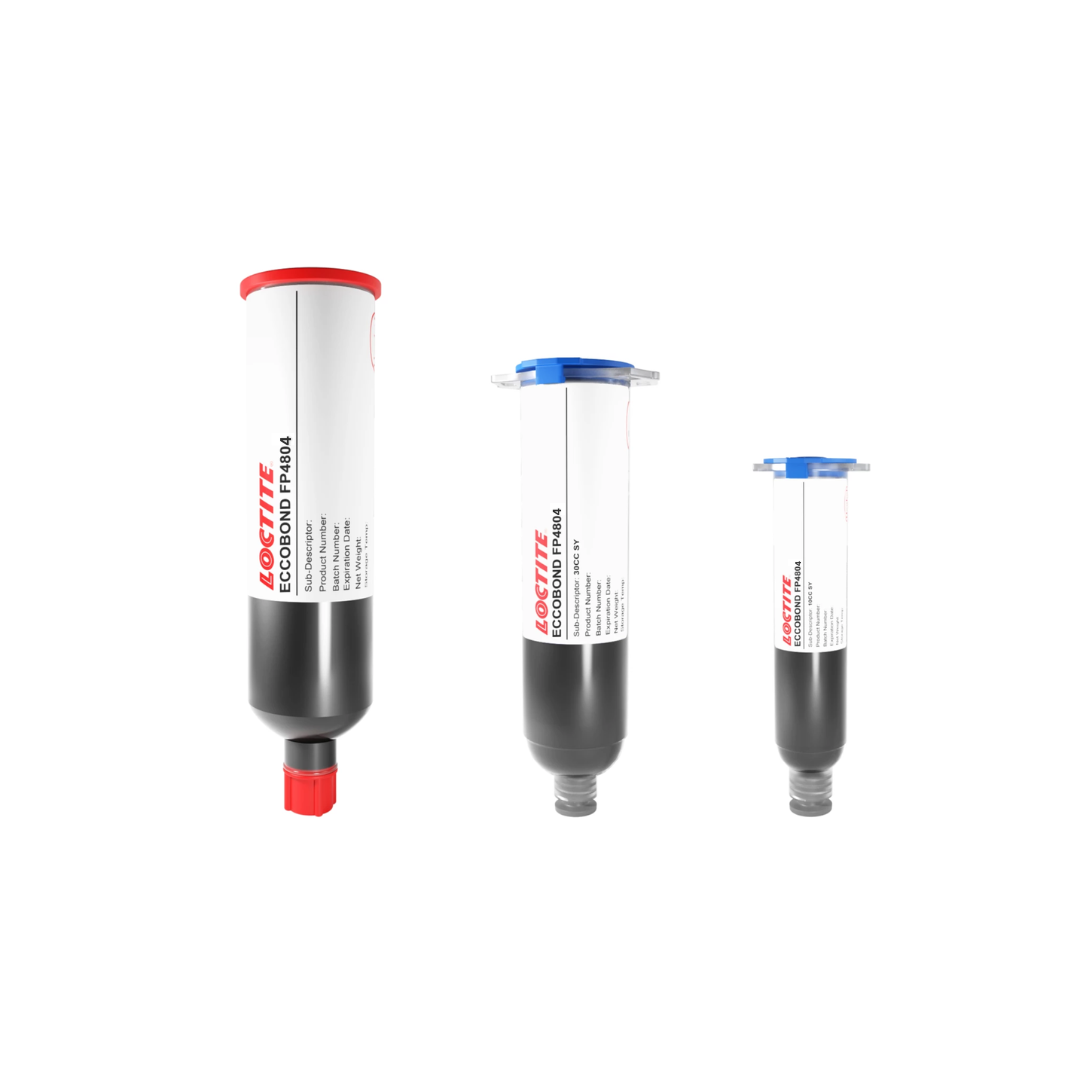

2. After removing from freezer, set the syringes to stand vertically while thawing.

3. Do not open the container before contents reach 22°C temperature. Moisture that collects on the thawed container should be removed prior to opening the container.

4. Do not re-freeze. Once thawed to 22°C, the adhesive should not be re-frozen.