PEAM-1769 Difunctional (meth)acrylate

Harmonization Code : 3906909090 | Acrylic polymers in primary form Others>Others

Main features

- Ultra low modulus

- Thermal stability

- High adhesion to various substrates

Product Description

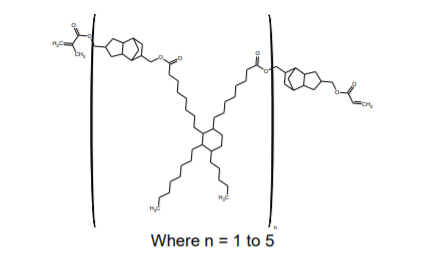

PEAM-1769 is a polyester acrylate/methacrylate that exhibits excellent adhesion, low warpage, and hydrophobicity. The oligomer has very high thermal stability and low volatility. It can be used as a base oligomer in a formulation or an additive. It is dark amber-colored, something that needs to be considered for light cure application.

PEAM-1769 is recommended for use as a base resin or an additive to reduce stress. It has excellent adhesion on most substrates with low stress and low shrinkage due to its high Tg polycyclic repeat units. The oligomer has good solubility in both aliphatic and aromatic solvents and monomers.

Technical Specifications

| General Properties | |

| Appearance Appearance Appearance at room temperature. | Amber liquid |

| Functionality | 2 |

| Molecular weight | 1769 g/mol |

| Thermal Properties | |

| Decomposition Temperature | >375 °C |

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | -40 °C |

| Weight Loss @ 300°C | 3.0 % |

| Other Properties | |

| Storage Temperature | 10 °C |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 20000 mPa.s |