Transceivers

Fiber optic components are used to form the fiber optic networking system. Because the fiber system is much more complicated than the former copper wired system, components needed for a fiber-optic network also are sophisticated, they include but are not limited to industrial transceivers, transmitters, optical fiber, and receivers. They are designed to operate in environments requiring reliable data transmission.

Application Requirements

Key Application Requirements:

- High initial transmission @ 680nm

- Retention of transmission is less important as the signal can be boosted

- MSL data is critical

- Trade-offs of transmission for higher MSL data is possible

- -40°C ~85°C operation temperature

- Device MAY or MAY NOT be MAP-molded

Key Material Requirements:

- Clear, high transmission, specifically @ 680nm

- Low moisture absorption

- Possibly filled for lower CTE for better MSL performance

- High hot hardness to be removed properly from molds

- High adhesion to lead frames (Ag, NiPdAu & Cu)

- If MAP-molded, low CTE is required

Pluggable Transceiver Modules

With form factors like SFP, QSFP, and CFP, these transceivers support various transmission speeds and distances, leveraging technologies such as Wavelength Division Multiplexing (WDM) and Silicon Photonics. Their reliability depends on factors like thermal management and signal integrity, ensuring stable performance over time.

Form Factors: SFP, SFP+, QSFP, QSFP-DD, CFP, CFP2, CFP4

Applications: Data Centers, Telecom Networks, Optical Fiber Communications

Key Technologies: Wavelength Division Multiplexing (WDM), Coherent Optical Transmission, Silicon Photonics

Reliability Considerations: Thermal Management, Signal Integrity, Aging Effects

Performance Metrics: Transmission Speed, Power Consumption, Distance Coverage

Fiber Optic Transceiver Modules

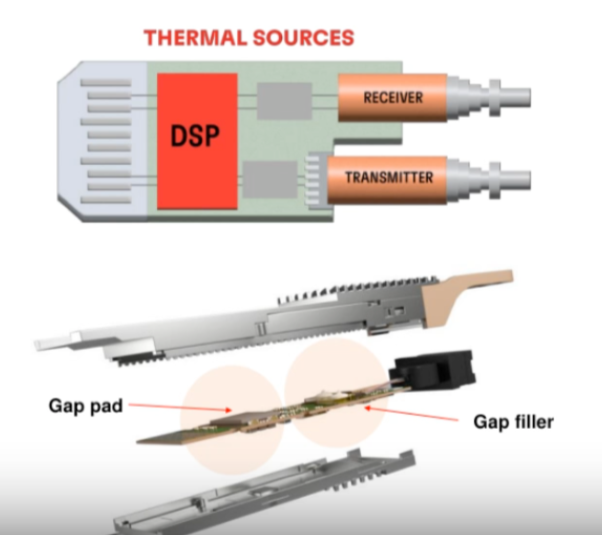

Fiber optic transceiver modules are the backbone of high-speed data communication, enabling fast and reliable optical signal transmission in data centers and telecom networks. These compact modules integrate key optoelectronic components including the transmitter (TOSA), receiver (ROSA), and DSP within limited board space.

As bandwidth demands rise and laser output increases 3–5 times, effective thermal management becomes crucial to avoid signal degradation and maintain long-term performance. Thermal Interface Materials (TIMs) such as gap pads and gap fillers are essential to dissipate heat from densely packed sources while meeting strict design constraints like finer pitches, low outgassing, and automation compatibility.

Thermal Management: Transceiver Modules

Thermal Challenges:

- Greater bandwidth

- Higher Density

- Compact Space Design (TOSA)

- Finer Pitches

- Increased Laser Power

Thermal Interface Material Requirements for Fiber Optic Transceiver Modules

- High Thermal Conductivity

- Low Oil Bleed

- Low Outgassing

- Process Automation

- High Reliability

- Thinner Bond Line

- Increased Product Life Cycle

Silicon-Free pads have been tested in various optical transciever device resulting in several degrees reduced temperatures

Products for Transceivers

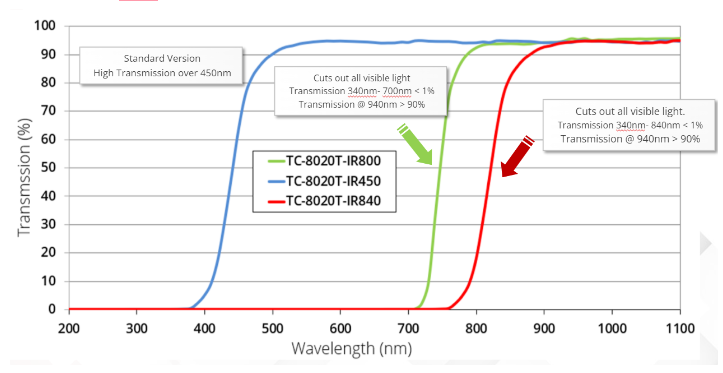

TC-8020 series is a high transmission, one component, optically clear epoxy molding compound that is specifically developed for sensor application and low-power LED encapsulation. Its excellent fluidity design helps it to become easily moldable and processable while offering excellent package performance and durability. This is supported by its long-term transmittance and post reflow reliability. We also provide various versions for TC-8020 to suit different application requirements.

PROPERTY | Units | XX-330HQ | TC-8020T | TC-8020L | TC-8020LS | TC-8020T-SR |

Standard | Low Stress Versions | Self-Release | ||||

Viscosity | Pa.s | 400 | 300 | 300 | 200 | 300 |

Spiral Flow @ 150°C | inches | 45 | 40 | 48 | 48 | 40 |

Hot Plate Gel Time @ 150°C | sec | 29 | 40 | 32 | 32 | 27 |

Glass Transition Temperature | °C | 125 | 125 | 115 | 100 | 125 |

CTE by TMA, Alpha1 CTE by TMA, Alpha2 | ppm/°C | 71 | 70 170 | 70 | 70 220 | 70 170 |

Moisture absorption PCT |

wt% | - | 0.17 | 0.16 | 0.17 | 0.17 |

2atm*100%RH*24hr@121°C | wt% | 2.9 | 3.2 | 3.2 | 3.8 | 3.2 |

Flexural Strength @25°C Flexural Modulus @25°C | MPa MPa | 130 | 135 3050 | 135 | 130 2950 | 135 3050 |

200°C * 4 hr, yellowing ∆b | - | 25 | 5 | 8 | 25 | 5 |

280°C * 30 min, yellowing ∆b | 49 | 33 | 42 | 45 | 37 | |

UV * 4 hr, yellowing ∆b | 26.5 | 11 | 16.5 | 16.5 | 11 | |

Transmittance @450nm,1mm | % | >90 | >90 | >90 | >90 | |

Refractive Index @633nm | - | 1.52 | 1.56 | 1.56 | 1.56 | 1.56 |

Comment | STD Item | STD Item for through-hole and surface mount component MSL3 | Low stress For better reflow performance MSL3 | Even lower stress for better reflow and thermal shock test performance MSL3 | Self-release technology without compromising vital properties | |