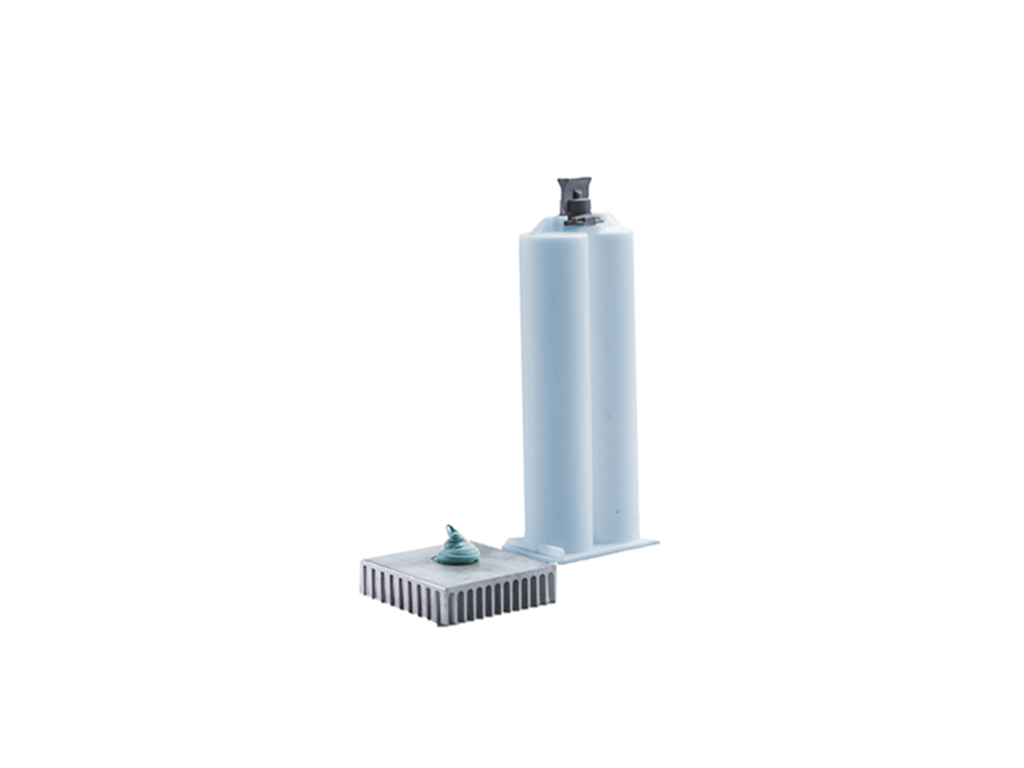

HLT 3500 | Two part Hybrid Thermal Gel

- Blue + White

- 3.5 Thermal Conductivity

- 0.44 Thermal impedance

Product Description

Honeywell HLT 3500 is a two-part hybrid gel product, dispensable and thermally conductive, which offers long-term reliability and superior softness. It exhibits low contact resistance, minimal oil bleeding at high temperatures and has very low thermal impedance under pressure. A balanced solution for vertical mounting that requires high TC before we go into the upper end of the product line. The enhanced bonding force between the polymer base and the filler largely improves the thermally conductive gel oil separation issue in storage. Prior to curing, the material maintains good thixotropic characteristics and low viscosity to be easily dispensed.

Related Product:

One-part hybrid gel does not requires curing, check HT3500. HT3500 shares the same thermal properties as HLT3500. However, some process properties are difference. Check the comparison between one-part and two-part hybrid thermal gel.

Key Features:

- Low contact resistance, BLT 0.1mm~5mm (TI vs Pressure curve)

- Easy to dispense (>100 g/min rate) and rework (with acetone, IPA or toluene)

- High compressibility for low stress applications (Thickness vs Pressure table)

- Long-term reliability, less oil separation, and low outgassing (<0.5%)

- No pump out, slump out and cracking

- Up to 200 °C applicable temperature

Typical Applications:

- Consumer electronics - gaming systems, portable devices

- Telecommunications equipment - routers, servers, memory modules, hard disk drives, solid state drives

- Automotive and aerospace - EV battery, power modules, capacitor cooling, lighting, charging units, ADAS

Curing Schedule:

HLT3500 can be cured at either 18 hours @room temperature or 30 minutes @100°C. You can optimize curing parameters for your own application needs. Check HLT Application Note to know storage and dispensing suggestions.

Technical Specifications

| General Properties | |

| Color Color The color | White - Blue |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 3.2 |

| Thermal Properties | |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 3.5 W/m.K |

| Thermal Impedance | 0.44 °C·cm²/W |

| Physical Properties | |

| Viscosity Viscosity Viscosity is a measurement of a fluid’s resistance to flow. Viscosity is commonly measured in centiPoise (cP). One cP is defined as the viscosity of water and all other viscosities are derived from this base. MPa is another common unit with a 1:1 conversion to cP. A product like honey would have a much higher viscosity -around 10,000 cPs- compared to water. As a result, honey would flow much slower out of a tipped glass than water would. The viscosity of a material can be decreased with an increase in temperature in order to better suit an application | 300,000 - 450,000 mPa.s |

Additional Information

HLT3500 Thermal Performance

HLT 3500 exhibits great Thermal impedance the more pressure you apply. At least 10psi pressure is suggested while applying it.

Additionally the oil bleeding is minimal. The test has been conducted by pasting a 25.4 x 25.4 x 1.5mm sample on A4 paper, either at Room temperature or at 125oC

Comparison between one-part and two-part hybrid gel

The HT series is one-part hybrid gel, which is already fully cross-linked before being applied. It could save time in assembly process and has longer shelf life. The HLT series products are two-part hybrid gels that can be cured in short-time after two-component mixing at room temperature. HLT products are cured in place, thus have better adhesion to components and are suitable for both horizontal and vertical applications. In total, the two series products share similar thermal and electrical properties.

Advantages Of Thermal Hybrid Gels