Busbars

Why do we need Busbars?

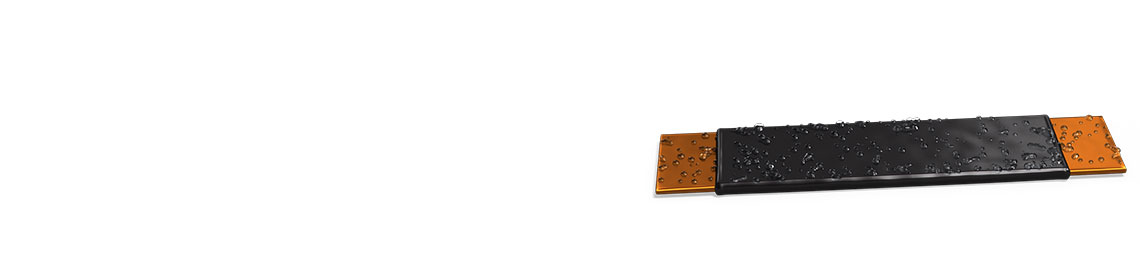

Busbars are metal bars that conduct a substantial current of electricity within a switchboard, distribution board, substation, battery bank or other electrical apparatus. Busbars are most commonly made of copper, aluminum or brass. The biggest disadvantages of copper over aluminum or brass are density and relative cost. For a given current and temperature rise, an aluminum conductor would be lighter and cheaper, even though its cross-section would be larger. Despite this and many attempts to replace it, copper still remains the predominant material choice for busbars.

Busbars are typically split into three families:

- Low Voltage Busbars

- Medium Voltage Busbar

- High Voltage Busbars (above 38,000V)

Low & medium voltage busbars are coated with an epoxy coating powder to provide electrical insulation and to reduce air spacing between busbars. This allows for safer, more efficient designs of switchgear equipment. High Voltage busbars are not easily if at all, covered by epoxy coating powders and require other methods of electrical insulation.

CAPLINQ has been actively developing, marketing and distributing epoxy coating powders for low and medium voltage power distribution. LINQSOL epoxy coating powders for busbars reduce the minimum busbar spacing requirement and are equally well suited for aluminum and copper busbars.

Key Application Considerations

Physical and Thermal Performance

- Impact resistance and flexibility

- Adhesion strength

- Moisture resistance

- Long-term thermal aging (RTI Rating)

- Flammability and ignition (UL94 V-0)

Electrical Performance

- High dielectric strength, surface/volume resistivity

- Excellent arc resistance, UL-CTI Rating

Environmentally Friendly

- Halogen-free and RoHS compliant

Great Manufacturing Productivity

- High build rate enables faster coating line speed

- Possible coating thickness to suit board voltage needs

Epoxy powder coating is a free-flowing, thermosetting dry powder. Epoxy Powder-Coated Insulation offers a high dielectric strength while creating durable insulation. Epoxy gives the bus bars a uniform thickness and smooth surface. The adhesive bond between the epoxy and bus bars results in lower thermal resistance and in a lower overall operating temperature.

Caplinq offers materials for all low & medium voltage power distribution purposes

For many years CAPLINQ has supplied a range of epoxy coating powders developed for medium voltage (600V – 38,000V) bus bar and switch gear applications. CAPLINQ is one of the few epoxy coating powder manufacturers with "switch panel-rated" material, meaning that their epoxy coating powders are qualified for use in Power Distribution Switch Boards. Given the critical nature of the application, the time and costs involved to pass UL-certification, major Power Management Companies reply on CAPLINQ and their family of UL-listed epoxy coating powders. All the products offered by CAPLINQ for busbar applications are internally tested and found to be UL-capable.

We offer epoxy coating powders that are specifically tailored for busbars, switchgear equipment, low and medium voltage applications and other power distribution applications. Key material properties of CAPLINQ's epoxy coating powders are:

- Powders that build to 3mm thickness for medium voltage

- Flexible powders for compact, low voltage distribution

- Smooth, uniform thickness for easy close-stack assembly

- Superior adhesion to copper or aluminum busbar

- Rapid build-rate improves cycles time and productivity

- Productivity and technical support

- Fine grinds to make-up particle size distribution

- Fluidizing aid to ensure uniform coverage

- Fluid Bed analysis to optimize quality, productivity & bed life

- Economical formulations enable flexible, one-powder, low & medium voltage manufacturing solutions

Performance expectations

Smooth Finish And Uniform Coating

It should achieve smooth, uniform coatings with either low or high thicknesses. No sagging is especially important for medium to high-voltage coating applications.

Flexibility For Thin Substrate

High toughness prevents cracks in coatings when thin conductors bend; Fine-grind high dielectric strength powders for spray applications

High Edge Coverage

High edge coverage enables powder build thickness, crack resistance, and corner toughness.

Build Thickness And High Build Rate

The build thickness capability brings thickening, adhesion across layers, and insulation voltage achieved. A high build rate of powder brings higher productivity yields.

Busbar coating guide

Here's our Busbar coating guide where we go over all the steps of the coating process. Cleaning, Masking, preheating, dipping, demasking and post curing are all discussed to give you optimization and troubleshooting ideas.

Linqsol Busbar Coating Products Selection Guide

| BCP-1000 | BCP-1504 | BCP-1507 | BCP-1509 | |

| Specific Gravity, g/cc | 1.45±0.05 | 1.52±0.05 | 1.50 | 1.50 |

| Glass Plate Flow | 18-22mm@150°C, 45° | 10-22mm@150°C, 60° | 19-20 mm@180°C | 19-20 mm@180°C |

| Hot Plate Gel Time | 70 sec@150°C | 45±15 sec@160°C | 60 sec@180°C | 60 sec@180°C |

| Edge Coverage, % | 45 | 45 | 45 | 45 |

| Hardness, shore D | >80 | >90 | - | - |

| Impact Resistance, cm | >50 | >50 | >50 | >50 |

| Dielectric Strength (kV/mm) | >42 | >35 | >35 | >35 |

| Flammability, UL94 | V-0 | V-0 | V-0 | V-0 |

| Min. Coating Thickness | 0.3mm | 0.3mm | 0.1mm | 0.3mm |

| Max. Coating Thickness | 1mm | 1mm | 2mm | 3mm |

| Electrostatic Spray | ■■■ | ■□□ | ■■■ | ■■■ |

| Dip Coating | ■□□ | ■■■ | ■■■ | ■■■ |

| Available Color | ●●●●● | ●● | ●●●●● | ● |

| Preheat Temperature | 180~240 °C | 150~180 °C | 180~230 °C | 180~230 °C |

| Curing Conditions | 200°C x 15min | 200°C x 15min | 200°C x 30min | 200°C x 30min |

Linqsol Busbar Coatings Guideline

| Part Geometry (width*thick) | Material | Voltage Rating | Required Coating Thickness (mils) | Preheat Temp (F) | Preheat Time (mins) | # of Dips | Cure Temperature (F) | Cure Time (mins) | Voltage |

|---|---|---|---|---|---|---|---|---|---|

| 2 to 8" * 1/4" | Copper | 600V | 20-30 | 340 | 20-24 | 1 | 380-400 | 20-24 | Low Voltage |

| Aluminum | 600V | 20-30 | 360 | 20-24 | 1 | 380-400 | 20-24 | ||

| 2 to 8" * 1/8" | Copper | 600V | 12-20 | 320 | 20-24 | 1 | 380-400 | 20-24 | |

| Aluminum | 600V | 12-20 | 320 | 20-24 | 1 | 380-400 | 20-24 | ||

| 1/4" | Copper | 5KV & 15 KV | 60-80 | 400-420 | 20-24 | 4 | 340-380 | 20-24 | Medium Voltage |

| 3/8" | Copper | 5KV & 15 KV | 60-80 | 390-410 | 20-24 | 3 | 340-380 | 20-24 | |

| 1/2" | Copper | 5KV & 15 KV | 60-80 | 370-385 | 20-24 | 3 | 340-380 | 20-24 | |

| 1/4" | Copper | 27 KV & 38 KV | 100-125 | 440-460 | 20-24 | 5 | 340-380 | 20-24 | |

| 3/8" | Copper | 27 KV & 38 KV | 100-125 | 420-440 | 20-24 | 4 | 340-380 | 20-24 | |

| 1/2" | Copper | 27 KV & 38 KV | 100-125 | 390-410 | 20-24 | 4 | 340-380 | 20-24 |