Photovoltaics

Photovoltaics, or solar cells, work by converting sunlight into electricity. They do this through a process called the photovoltaic effect.

Here's how it works:

- Solar cells are made up of layers of semiconductor material, such as silicon.

- When sunlight hits the solar cell, it causes the semiconductor material to release electrons, creating a flow of electricity.

- The electricity is then collected by metal contacts on the surface of the solar cell and is sent to an inverter.

- The inverter converts the direct current (DC) electricity produced by the solar cell into alternating current (AC) electricity, which is the type of electricity used in homes and businesses.

- The AC electricity is then sent to the electrical panel, where it can be used to power appliances and other devices in the home or business.

Solar cells are a clean, renewable source of energy and are becoming increasingly popular as a way to generate electricity. They are also relatively easy to install and require minimal maintenance once they are set up.

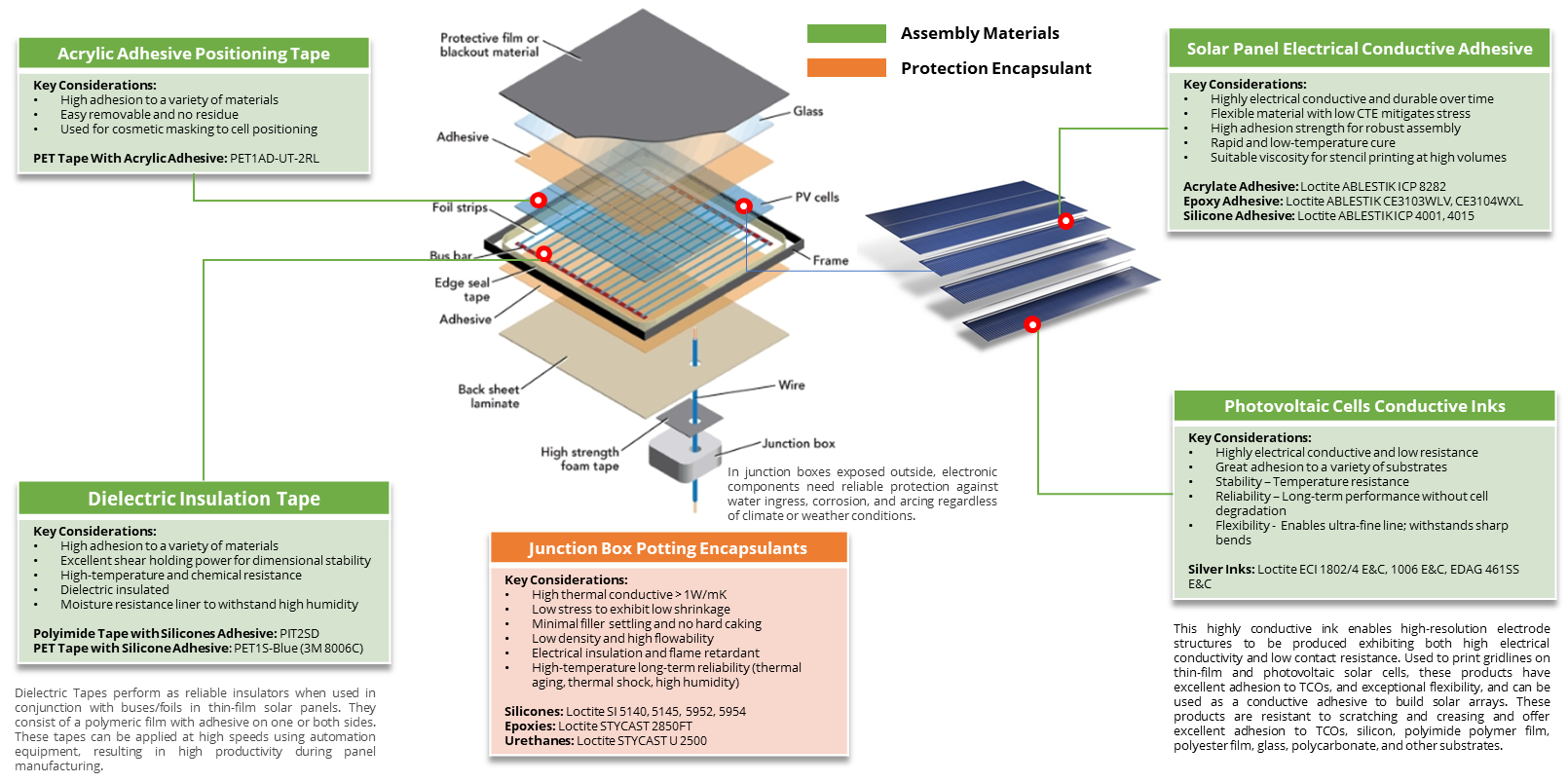

As Photovoltaic technology becomes more popular, so does the demand for high-performance solutions to facilitate this energy transition. Improved solar function, operation, and stability in extreme temperatures and UV exposures are of the utmost importance.

Moisture and weather-resistant sealants and adhesives are on the top of the list requiring long term reliability and adhesion.This adhesion needs to be excellent on glass and metal frames. Encapsulants that improve solar module performance are needed to protect from the weather conditions and to prevent corrosion and delamination. Finally, potting agents must be designed to withstand the elements, and be fire-resistant and stable over a wide range of temperatures.

| Solar Panel Electrically Conductive adhesives |

Key considerations:

|

| Photovoltaic cells conductive inks |

Key considerations:

|

ECI 1802/4, ECI 1006, EDAG 461SS |

Electrically conductive adhesives

These materials need to be flexible and provide high adhesion to non noble substrates. The throughput has to be very high as well as their electrical conductivity. Since these are mainly used for assembly, the adhesion must be reliable and robust to ensure continuous and

Recommended products

- LOCTITE ABLESTIK ICP 8282 | Acrylate. Snap curable for high throughput photovoltaic and solar panel interconnects

- LOCTITE ABLESTIK CE3103WLV | Epoxy. Pb-free alternative to solder for bonding Sn or AgSn coated Cu ribbon to front contact (TCO) of thin film PV cells

- LOCTITE ABLESTIK CE3104WXL | Epoxy. Pb-free alternative to solder for SMD component attach on non noble Sn, Sn/Pb and OSP coated CU substrates

- LOCTITE ABLESTIK ICP 4001 | Silicone. Bonding of noble passive components onto noble terminated lead frames & contact bonding of c-Si PV cells to Ag tracks

Flexibility and reliability under sharp bends is the main deciding factor for these materials. These silver-filled electrically conductive materials need to have very low resistance while also being able to bond without breaking on a variety of flexible substrates.

These highly conductive inks enable high resolution electrode structures to be produced exhibiting both high electrical conductivity and low contact resistance. Used to print gridlines on thin film and photovoltaic solar cells, these products have excellent adhesion to TCOs, exceptional flexibility and can be used as conductive adhesives to build solar arrays. These products are resistant to scratching and creasing and offer excellent adhesion to TCOs, silicon, polyimide polymer films, polyester film, glass, polycarbonate and other substrates.

Recommended products

- LOCTITE EDAG 461SS E&C | Flexible conductive ink for ITO coated films, membrane switches and flexible circuits