Smart Cards

Smartcards and RFIDs are being used in the vast majority of cards and passes out there. Oyster cards? OV chipkaarts? Credit and debit cards with wireless functions? They are all smartcards, using a tiny IC to store and communicate your pass information. The visible side that you can see on your card is the contact side while from the flip side we have the chip that is pulling all the ropes.

A common assembly looks like the following

- Carrier substrate film or tape. This is typically a glass epoxy material that is metallized with Cu, Ni/Au or other metallizations.

- Die. Size ranging from 1 to 5 mm2 with a die thickness of 150-180um that keeps getting thinner.

- Plastic card body. Multiple materials such as ABS,PET or PVC are being used. These are ~0.7-1mm thick cards with a small cavity that accepts the IC.

The semiconductor die needs to be bonded to the substrate and the plastic body and be protected from the mechanical challenges that these cards are being exposed to on a daily basis.

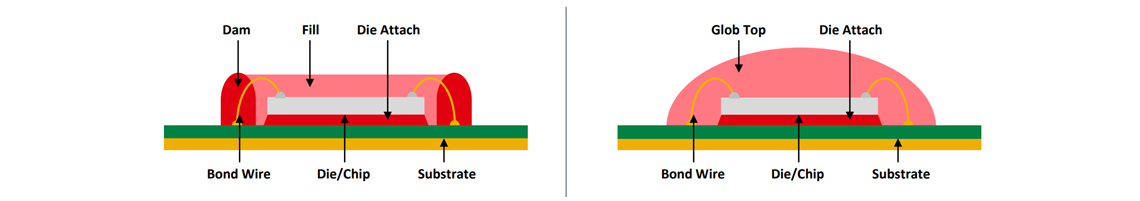

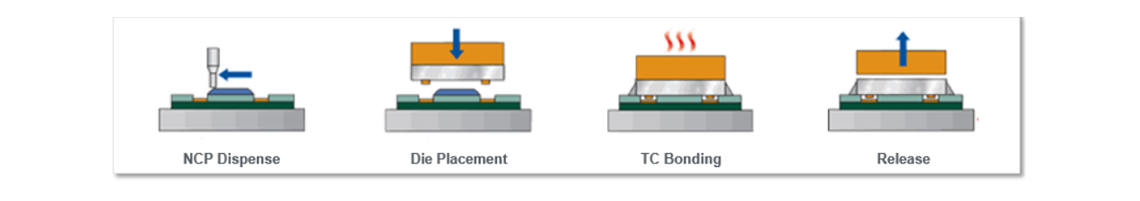

Die attach materials and Encapsulation are the main focus points when it comes to smartcard ICs, though we also offer Smartcard interleaver antistatic film. They are used to keep the die in place, protect the bare dies and wires (if we are not using a flip chip) and to mechanically and chemical protect from environmental hazards. There are glob top, dam and fill, underfill and transfer molding options with most of them being heat curable and with some of them being UV or even dual cured.

CAPLINQ offers a complete portfolio designed for smartcard modules. These product pass all the standard reliability tests such as HTS, LTS, Aging, Thermal shock, 3 wheel bend test etc.