Hysol GR30 | Black Epoxy Mold Compound

- Designed for TO220 & TO247

- Improved version of GR300

- Faster cycle time for Automold

Product Description

Hysol GR30 was formulated to have better electrical properties then its predecessor. This means that the GR30 passes higher levels of high-temperature reverse bias (HTRB) than the standard GR300 and offers excellent HTRB performance. Additionally, it is an environmentally "Green" product, meaning that it doesn't contain any bromine, antimony or phosphorus flame retardants. Previous MG-series EMC dominated the space for power semiconductors but used halogen-containing flame retardants. This next generation epoxy mold compound replaces these older generation products. It is designed to achieve JEDEC Level 1 requirements at 260°C reflow temperature on Nickel or Nickel-plated leadframes. And to top that up, it meets UL 94 V-0 Flammability at 1/8 inch (3.18mm) thickness. This product is an alternative that can easily replace the discontinued Kyocera KE-G300S.

Available Versions:

- GR350HT (High Thermal Conductivity of 1.95 W/mK)

Key Features

- Low thermal stress and excellent electrical stability.

- Excellent reliability performance on TC, PCT, etc.

- Meet with all type devices especially MOSFET, Schottky, etc.

- Good delam performance after stress test

- Good adhesion performance

- Excellent workability - 500 shots continuous molding

- Suitable for Conventional/MGP/Auto Mold type

- Green material without Br/Sb in compliance with ROHS.

- Meet UL94 V-0 flammability rate at 1/8 inch thickness.

Key Features for Rotor Magnet Fixing

- Good filling ability for gap around magnets in rotor.

- Good binding force for rotor and magnet.

- Excellent reliability performance at working temperature.

- Fast cure for high effective units per hour.

Technical Specifications

| General Properties | |

| Color Color The color | Black |

| Filler Content | 80 % |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 1.94 |

| Thermal Properties | |

| Glass Transition Temperature (Tg) Glass Transition Temperature (Tg) The glass transition temperature for organic adhesives is a temperature region where the polymers change from glassy and brittle to soft and rubbery. Increasing the temperature further continues the softening process as the viscosity drops too. Temperatures between the glass transition temperature and below the decomposition point of the adhesive are the best region for bonding. The glass-transition temperature Tg of a material characterizes the range of temperatures over which this glass transition occurs. | 178 °C |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 1.0 W/m.K |

| UL 94 Rating UL 94 Rating Flammability rating classification. It determines how fast a material burns or extinguishes once it is ignited. HB: slow burning on a horizontal specimen; burning rate less than 76 mm/min for thickness less than 3 mm or burning stops before 100 mm V-2: burning stops within 30 seconds on a vertical specimen; drips of flaming particles are allowed. V-1: burning stops within 30 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. V-0: burning stops within 10 seconds on a vertical specimen; drips of particles allowed as long as they are not inflamed. 5VB: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may develop a hole. 5VA: burning stops within 60 seconds on a vertical specimen; no drips allowed; plaque specimens may not develop a hole | V0 |

| Electrical Properties | |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 1.1x1016 Ohms⋅cm |

| Mechanical Properties | |

| Molded Shrinkage | 0.24 % |

| Chemical Properties | |

| Moisture absorption | 0.42 % |

| Physical Properties | |

| Spiral Flow @ 175°C | 66 cm |

| Curing Conditions | |

| Transfer Pressure | 40 - 100 kg/cm2 |

| Transfer Time | 5 - 30 s |

Additional Information

Designed for TO220 & TO247 devices

TO220 and TO247 are big, bulky packages, so molding these products with a standard mold compound is fairly easy without using any fine fillers. The trouble with these packages however is that epoxy mold compounds used typically fail Hig Temperature Reverse Bias (HTRB) testing, which exposes the device to humidity and temperature while the device is under BIAS. Devices often experience "gate leakage" under these conditions and fail catastrophically.

Furthermore, these devices are often used using a Nickel (Ni) plated Cu leadframe, which is very difficult to adhere to. Customer reliability testing on TO3P, TO220, and TO252 packages using GR30 has demonstrated excellent adhesion of the EMC to Nickel (Ni) plated Cu leadframe, with minimal to zero delamination observed after testing. Specifically, GR30 utilized in TO220 packages exhibited no delamination after TCT500 (-65°C to 150°C) and PCT96 tests. For GR30 in TO252 packages, only non-critical delamination was observed after the same TCT500 (-65°C to 150°C) and PCT96 tests.

GR30-ON for Automotive TO247/TO220

| Item | Unit | GR30 | GR30-ON |

|---|---|---|---|

| EMC Grade | - | GR30 | GR30-ON |

| Epoxy resin | - | EOCN + DCPD | EOCN + LSR* |

| Flame Retardant | - | Inorganic MH | Self Extinguish |

| Filler shape | - | Angular & Spherical | Angular & Spherical |

| Filler max sieving size | µm | 150 | 150 |

| Filler content | wt% | 80 ± 1 % | 84 ± 1 % |

| Spiral flow | inch | 24 | 27 |

| Gelation time @ 175°C | sec | 18 | 25 |

| Flexural strength @ 25°C | MPa | 110 | 110 |

| Flexural modulus @ 25°C | MPa | 15640 | 17600 |

| Tg | °C | 175 | 165 |

| Coefficient of thermal expansion α1 | ppm/°C | 14 | 10 |

| Coefficient of thermal expansion α2 | ppm/°C | 55 | 38 |

| Thermal conductivity | W/m·K | 1.0 | 0.9 |

| Specific gravity | g/cm³ | 1.94 | 1.90 |

| Na+ (extracted water) | ppm | 5 | 3 |

| Cl- (extracted water) | ppm | 8 | 11 |

| pH (extracted water) | - | 5.2 | 5.3 |

| Water absorption (PCT) | wt% | 0.45 | 0.38 |

| Flammability (UL94) | - | V-0 | V-0 |

Note:

1. LSR* stands for low stress resin with self extinguish property;

2. GR30-ON is commerical product for TO247/TO220 automotive application;

3. Property data are typical value for reference only, not to be used as quality guarantee

GR30 and GR30-ON are high-performance EOCN-based epoxy molding compounds with optimized filler loading, UL94 V-0 flammability, and a balanced set of mechanical, thermal, and electrical properties for reliable encapsulation. GR30 is well suited for applications that prioritize high Tg and stiffness, while GR30-ON, with its higher spiral flow and lower CTE, is ideal for more complex or stress-sensitive package designs allowing customers to select the grade that best matches their device, process, and reliability requirements.

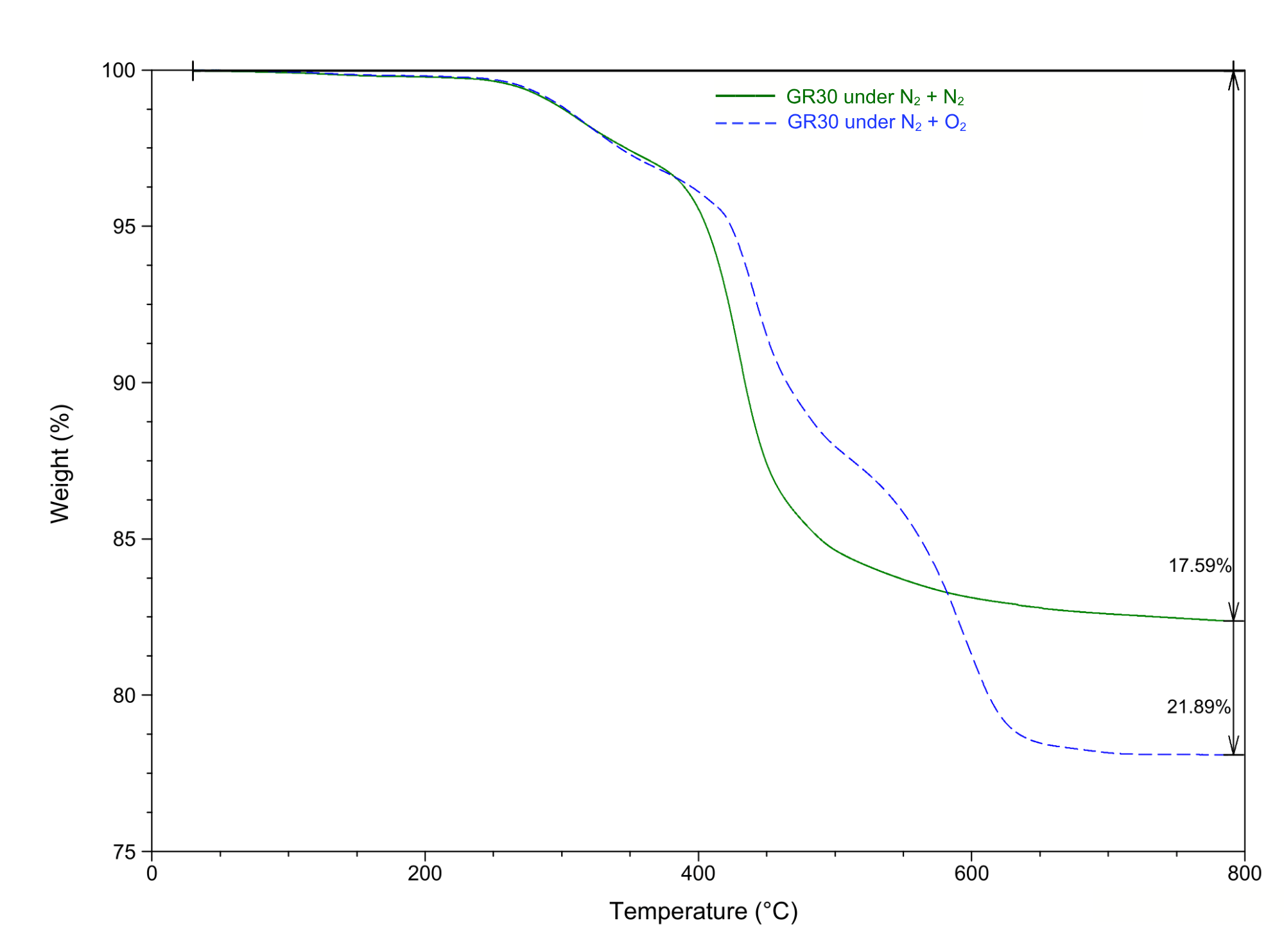

GR30 Thermal Degradation Performance

In a mixed oxidizing atmosphere, the main event shifts and broadens: T₅% = 424 °C, T₁₀% = 466 °C, and the DTG maximum moves to Tmax = 458 °C with a lower peak rate (0.0028 %/°C). The higher Tmax coupled with a reduced final residue (ash = 78.11 % at 800 °C, total mass loss = 21.89 %) reflects early-stage oxidative stabilization (which can delay the peak rate temperature) followed by oxidation of carbonaceous char at higher temperatures, increasing overall mass loss versus N₂. The tailing DTG in the 450–600 °C region captures progressive char burn-off typical for epoxy systems exposed to oxygen.

| Parameter | Under Pure N₂ | Under N₂ + O₂ | Notes |

|---|---|---|---|

| Initial Mass | 100 % | 100 % | Normalized baseline |

| T5% (5 % mass loss) | 406 °C | 424 °C | T5% determined from TGA curve crossing 95 % mass remaining |

| T10% (10 % mass loss) | 434 °C | 466 °C | T10% corresponds to 90 % remaining mass |

| Tonset (Extrapolated Tangent) | ≈ 405 °C | ≈ 420 °C | Intercept from first DTG inflection |

| Tmax (DTG peak) | 430 °C @ 0.00385 %/°C | 458 °C @ 0.0028 %/°C | Tmax = temperature of maximum mass-loss rate |

| Main Decomposition Range | 400–480 °C | 420–500 °C | Slightly delayed oxidation due to oxidative stabilization lag |

| Total Mass Loss (to 800 °C) | 17.59 % | 21.89 % | More oxidative degradation in mixed gas |

| Char/Ash Yield @ 800 °C | 82.41 % (char residue) | 78.11 % (oxidized ash) | Indicates higher carbonization in inert N₂ and greater oxidation under N₂ + O₂ |

| Property | Unit | 25 °C | 150 °C | 175 °C |

|---|---|---|---|---|

| Volume Resistivity | Ω·cm | 13 | 0.24 | 0.1 |

| Flexural Strength | MPa | 108 | 76 | 57 |

| Flexural Modulus | MPa | 16 702 | 2 273 | 1 893 |

| Adhesion Strength to Cu (post PMC) | N | 411 | 353 | 354 |

| Adhesion Strength to Cu (post MSL3) | N | 14 | 22 | 8 |

| Adhesion Strength to Cu (post PMC) | MPa | 7.12 | 6.11 | 6.13 |

| Adhesion Strength to Cu (post MSL3) | MPa | 0.24 | 0.38 | 0.14 |

| Property | Unit | GR30 |

|---|---|---|

| Glass Transition Temperature | °C | 179 |

| Coefficient of Thermal Expansion α1 | ppm/°C | 14 |

| Coefficient of Thermal Expansion α2 | ppm/°C | 54 |

| Ion Content | ||

| Chlorine (Cl−) | ppm | 6 |

| Sodium (Na+) | ppm | 3 |

| Potassium (K+) | ppm | 1 |

| Bromine (Br−) | ppm | 0 |

| Sulfate (SO42−) | ppm | 10 |

| Dielectric Constant at 1 MHz | — | 3.97 |

| Electrical Conductivity (oEW) | µS/cm | 17 |

| Thermal Conductivity | W/m·K | 1.09 |

GR30 has been successfully used for Magnet Fixing in Electric Vehicle Rotors

Epoxy molding compound is used to bond the magnet and rotor core by using a transfer molding method. There are several slots that go through the core. The permanent magnets are inserted in the slot and then the mold compound is filled into the gap to bind the magnet and the rotor core together.

The critical function of the material is to have a strong binding force between the magnet and the rotor core while also having a good filling capability. It should also have excellent reliability at working temperature. GR30 is a green material without Br/Sb, in compliance with ROHS that can cure fast for high Units per Hour.

Molding compounds have already been used in Rotors with Iron as a base material and with rotor working speeds up to 20000rpm and working temperatures up to ±150°C. They pass both Temperature cycling and High temperature ATF resistance tests while retaining 100% of their flexural strength and flexural modulus. This highlights the product's excellent property stability post post-automotive fluid resistance testing.

GR30 Properties

| PROPERTY | UNIT | GR30 |

| Filler Seiving Cut Size | um | 100 |

| Average Filler Size | um | 21 |

| Filler Content | % | 80 |

| Specific Gravity | - | 1.94 |

| Spiral Flow @175°C | cm | 66 |

| Hot Plate Gel Time @175°C | sec | 19 |

| Glass Transition Temperature | °C | 178 |

CTE by TMA, α1 CTE by TMA, α2 | ppm ppm | 14 54 |

Thermal Conductivity | W/m·K | 1.0 |

Flexural Strength @25°C Flexural Modulus @25°C | MPa Gpa | 110 15.6 |

| Mold Shrinkage | % | 0.24 |

| Flame Retardancy | UL-94 | V-0 |

| Shelf Life and Storage Condition | mon | 6 months at 5°C |

Device Information

| EMC | GR30 |

| Project Condition | LVM |

| Package Type | Rotor |

| Base Material | Fe |

| Rotor Working Speed | 20,000 rpm |

| Working Temperature | ≥ 150°C |

| Mold Model | Automold |

Reliability Test Procedure

| ATF Resistance | Test Condition |

| Temperature Cycling | 25°C → (155°C for 40hr → -45°C for 8hr) * 4 or 8 cycles → 25°C |

| High Temperature Test | 25°C → 155°C for 1000 hr or 2000 hr (cool down to room temperature every 200 hrs to add ATF) → 25°C |

GR30 Beta Site Reliability Test Results

ATF Resistance Test: Temperature Cycling

| Property | Property Retention after 16 days |

| Flexural Strength at RT | 100% |

| Flexural Modulus at RT | 100% |

| Flexural Strength at 260°C | 100% |

| Flexural Modulus at 260°C | 100% |