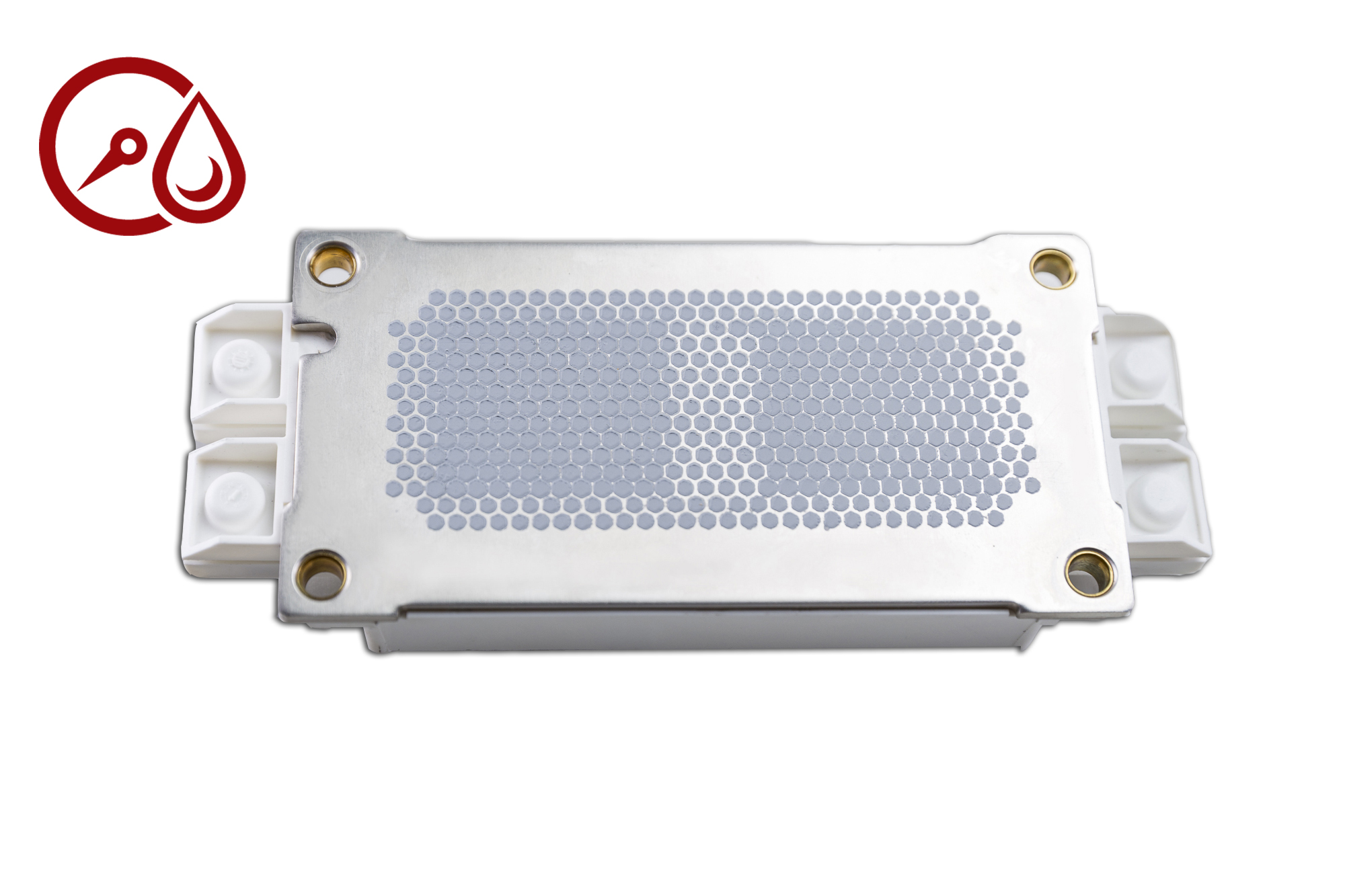

PTM 7950-SPS | Phase Change Paste

- 0.04 Thermal Impedance

- 8.5 Thermal Conductivity

- Slow drying solvent

Product Description

PTM7950SPS is an identical version of PTM7950-SP but with a slow drying solvent (S). PTM7950SPS is the paste version of PTM7950, a super highly thermally conductive Phase Change Material (PCM). It is designed to minimize thermal resistance at interfaces, maintain excellent performance through reliability testing, and provide scalable application at a competitive cost. Based on a novel polymer PCM system, PTM7950 exhibits excellent interface wettability during typical operating temperature ranges, resulting in extremely low surface contact resistance. PTM7950SPS is designed for automatic stencil printing manufacturing process, which largely helps with productivity and could be printed as low as 0.1mm. Check the comparison with pad version, PTM7950SPS needs extra drying steps after being printed and before assembly. Also, PTM7950SPS requires longer time for drying compared with standard PTM7950SP.

Available Versions: (Check the difference between pad and paste version)

- PTM7950 Pad, easy apply and no drying steps

- PTM7950-SP, paste version for automatic stencil printing

- PTM7950-SPS, paste version with slow drying solvent

Key Features:

- Super low thermal impedance (TI vs Pressure Curve PTM7950)

- Silicone-free, no pump out, bleed out, dry out issue

- Industry proven superior long-term reliability (Reliability Report PTM7950)

- Min BLT~20um, typical BLT is below 50um (BLT vs Pressure Curve PTM7950)

- 30~40 psi pressure is needed for usage (PCM Application Note)

Highly Recommend For:

- Power modules/inverters in e-mobility and power distribution

- High performance IT/enterprise computing devices

- Consumer electronics, high performance IC

- High power LED applications

Know More about PTM7950's superior thermal performance and long-term reliability.

Drying Schedule:

- 10 mins at 120°C or

- 25 mins at 100°C or

- 48 hours at Room temperature

PTM7900 and PTM7950 are closely related thermal interface materials with slight differences in performance. PTM7950 features a softer composition, higher thermal conductivity, and lower thermal impedance, enhancing its overall thermal performance. Aside from these improvements, both materials share similar characteristics.

Technical Specifications

| General Properties | |

| Specific Gravity Specific Gravity Specific gravity (SG) is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. For liquids, the reference substance is almost always water (1), while for gases, it is air (1.18) at room temperature. Specific gravity is unitless. | 2.5 |

| Thickness range | 0.25 mm |

| Thermal Properties | |

| Specific Heat Capacity Specific Heat Capacity Specific heat capacity is the amount of heat energy required to raise the temperature of a substance per unit of mass. The specific heat capacity of a material is a physical property. It is also an example of an extensive property since its value is proportional to the size of the system being examined. | 0.97 J/g.K J/(g⋅°C) |

| Thermal Conductivity Thermal Conductivity Thermal conductivity describes the ability of a material to conduct heat. It is required by power packages in order to dissipate heat and maintain stable electrical performance. Thermal conductivity units are [W/(m K)] in the SI system and [Btu/(hr ft °F)] in the Imperial system. | 8.5 W/m.K |

| Thermal Impedance | 0.04 °C·cm²/W |

| Electrical Properties | |

| Volume Resistivity Volume Resistivity Volume resistivity, also called volume resistance, bulk resistance or bulk resistivity is a thickness dependent measurement of the resistivity of a material perpendicular to the plane of the surface. | 2.1x1014 Ohms⋅cm |

Additional Information

Honeywell PTM7950 is one of the most successful TIM products used in high power inverters and high performance computing devices. Ultra-low thermal impedance with minimum achievable BLT and superior long-term reliability make PTM7950 stand out from the competitors. PTM7XXX series also presents stability among vertical applications and pass automotive standard vibration test (Check the Vibration & Shock Test Report), thus PTM7XXX is currently widely used in automotive applications such as power inverters.

What is the difference between PTM7950 and PTM7950SP, PTM7950SPS?

PTM7950SP is the paste version of PTM7950 pad, they share exact the same properties. PTM7950SP has been added solvent to make it printable, thus needs extra drying step before assembly. Solvents can be adjusted so that the drying process is faster or slower. PTM7950SPS is slow drying version of PTM7950SP, it is designed for those who would like to have longer working windows.

How to achieve the minimum thermal resistance of PTM7950?

To achieve as low thermal resistance as possible for your device, you choose the material with high thermal conductivity, minimize the bondline thickness, and also improve the surface wettability. PTM7950 excels at the thermal performance since it could achieve minimum bondline as 17um and high TC as 8.5 W/m.K. Clamping pressure (30~40 psi) and temperature (at least 30mins@60°C) are suggested to achieve a minimum bond line thickness of the phase change material, typically less than 1.5 mil (0.038mm) for best performance. The material must go through the phase change temperature to exhibit entitlement performance. (Check PCM Application Note) .

The figures below shows the TI achieved using PTM7950.

What are the reliability expectations of the PTM7950?

All the 7XXXseries (PTM7000, PTM7900 & PTM7950) pass the three major reliability tests with flying colours. Honeywell does not test beyond 1000 cycles, 92 hrs HAST and 1000 hrs HTS. However, anecdotally, some automotive customers have taken 7900 to beyond Honeywell’s limits and have found it to pass shock and vibration, longer temperature cycling and longer temperature and humidity soak. (Check Reliability Report PTM7950)

If your lifetime performance is defined mainly by power cycling, then you also check the PTM6000 series which will have the longest life. The main difference between the 7XXX products is the filler content which makes PTM7950 the most conductive.